Punching hole distance adjustable compound die for double-long-hole workpiece

An adjustable and composite mold technology, applied in the field of composite molds, can solve the problems of lower production efficiency, less than guaranteed accuracy, waste of time and labor, etc., and achieve the effects of improving precision and quality, prolonging service life, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

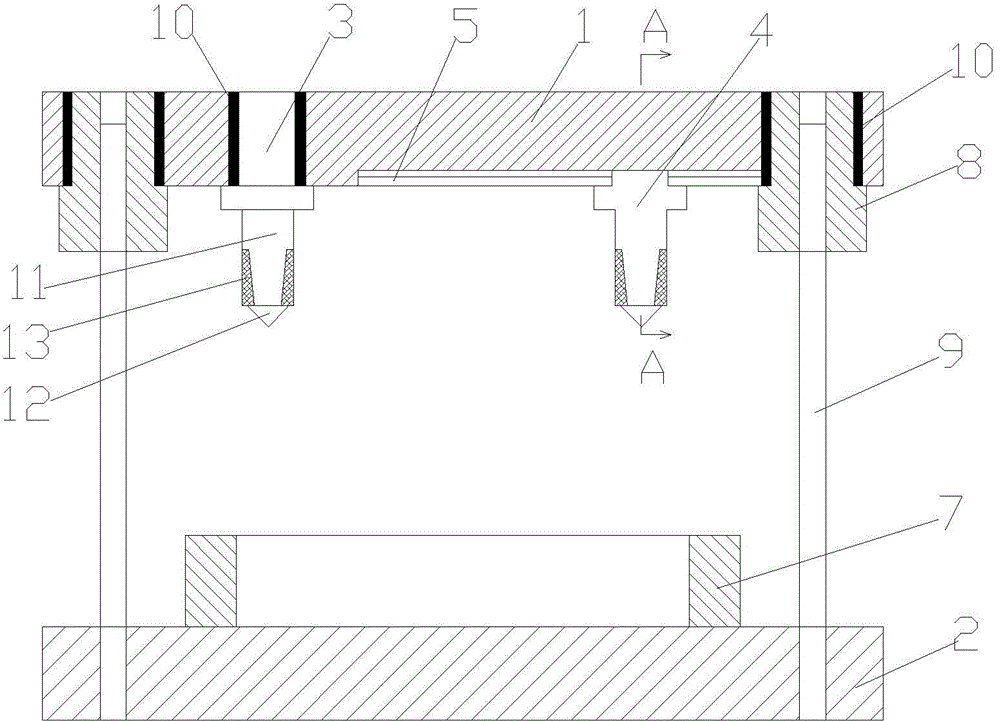

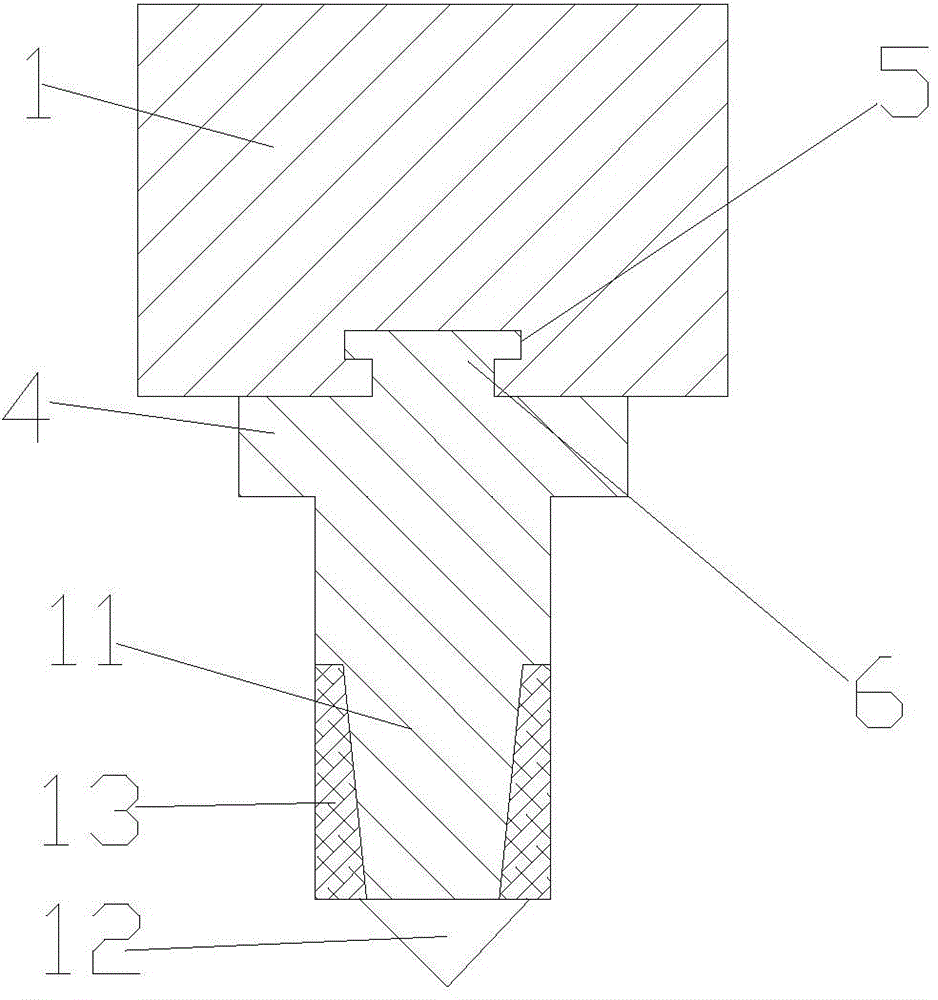

[0012] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0013] attached figure 1 , 2 It is a compound die with adjustable punching distance for a double long-hole workpiece according to the present invention, which includes an upper die base 1 and a lower die base 2 installed oppositely, and a fixed punch 3 is arranged at an interval at the bottom of the upper die base 1 and a movable punch 4; the upper mold base 1 is provided with a dovetail groove 5; the upper part of the movable punch 4 is provided with a dovetail block 6; the dovetail block 6 is arranged in the dovetail groove 5; the lower Die base 2 is provided with die 7, and described punch comprises guiding part 11 and working part 12; Described guiding part 11 is arranged on the below of working part 12; Described guiding part 11 is a cone, and described working part 12 An alloy ring 13 is provided on the outer periphery of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com