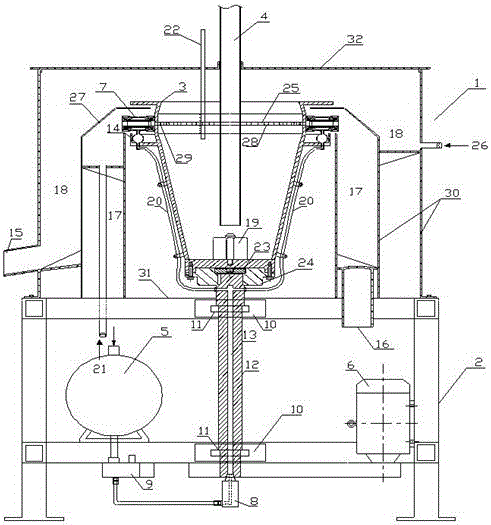

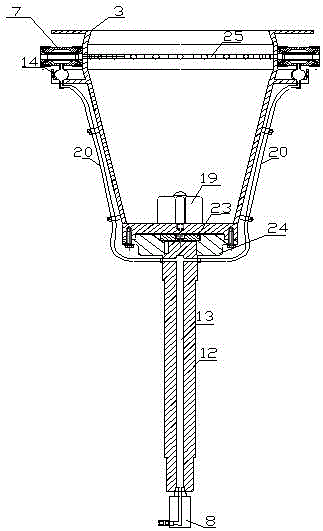

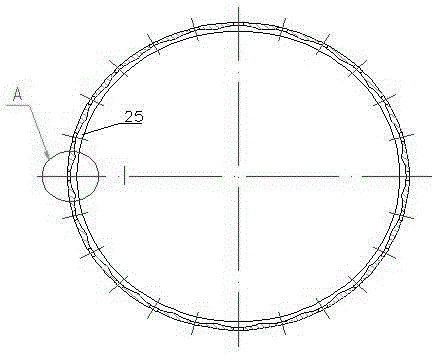

A kind of centrifugal beneficiation device and beneficiation method thereof

A technology of centrifugation and centrifugal drum, which is applied in the direction of centrifuges, chemical instruments and methods, centrifuges with rotating drums, etc., which can solve the problems of limited application range and low sorting efficiency, and reach the lower limit of sorting particle size Low, improve concentrate grade and production capacity, high separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0077] The selected raw ore contains 0.19% tungsten. The tungsten minerals in the raw ore mainly exist in the form of scheelite and wolframite. Only 6.47%, tungsten recovery rate is only 53.38%. A kind of centrifugal beneficiation device and its beneficiation method of the present invention are used for separation. When the ore feeding concentration is 25%, the ore feeding speed is 1.82L / min, the rotating speed of the centrifugal drum is 650r / min when the centrifugal drum is working normally, and the ore pulp is fine When the concentration is -0.074mm and the content accounts for 70%, after the above steps of separation, the obtained tungsten concentrate contains 17.35% tungsten and the recovery rate of tungsten is 80.18%.

Embodiment 2

[0079] The selected raw ore contains 0.23% tungsten. The tungsten minerals in the ore mainly occur in wolframite, and the embedded distribution characteristics are relatively complicated, and the embedded distribution particle size is relatively fine. The tungsten concentrate obtained by conventional centrifugal separation technology contains only 8.91% tungsten. The recovery rate of tungsten is only 61.55%. A kind of centrifugal beneficiation device and its beneficiation method of the present invention are used for separation, when the ore feeding concentration is 23%, the ore feeding speed is 2.15L / min, the rotating speed of the centrifugal drum is 580r / min when the centrifugal drum is working normally, and the ore pulp is fine When the concentration is -0.074mm and the content accounts for 68%, after the above steps of separation, the obtained tungsten concentrate contains 20.28% tungsten and the recovery rate of tungsten is 83.65%.

Embodiment 3

[0081] The selected raw ore contains 0.25% tungsten. The tungsten minerals in the ore are mainly scheelite, with a small amount of black tungsten ore. The tungsten concentrate obtained by advanced centrifugal beneficiation technology contains only 5.38% tungsten, and the recovery rate of tungsten is only 55.68%. A kind of centrifugal beneficiation device and its beneficiation method of the present invention are used for separation. When the ore feeding concentration is 20%, the ore feeding speed is 1.95L / min, the rotating speed of the centrifugal drum is 710r / min when the centrifugal drum is in normal operation, and the ore pulp is fine When the concentration is -0.074mm and the content accounts for 75%, after the above steps of separation, the obtained tungsten concentrate contains 24.63% tungsten and the recovery rate of tungsten is 86.21%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com