A kind of nano black selenium peroxide mimetic enzyme and preparation method thereof

A technology of black selenium peroxide and peroxidase, applied in chemical instruments and methods, physical/chemical process catalysts, elemental selenium/tellurium, etc., can solve problems such as difficult purification, high price, and easy inactivation of natural enzymes , to achieve the effect of easy separation and purification, low price and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] 1. Preparation of nanometer black selenium peroxide mimetic enzyme:

[0031] step:

[0032] Weigh 0.222g selenium dioxide (SeO 2 ), dissolved in 5 mL of deionized water at room temperature, added 0.8 mL of concentrated sulfuric acid with a mass concentration of 98%, stirred for 5 minutes, added 30 mL of glycerol, continued to stir for 30 minutes, transferred the mixture to an autoclave, and reacted at 180 ° C After 6 hours, the product was centrifuged, and the centrifuged precipitate was washed three times with deionized water and ethanol respectively, and then vacuum-dried at 60° C. to obtain nano black selenium powder.

[0033] result:

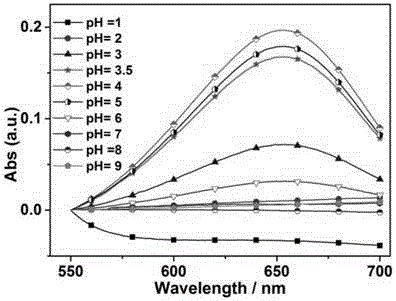

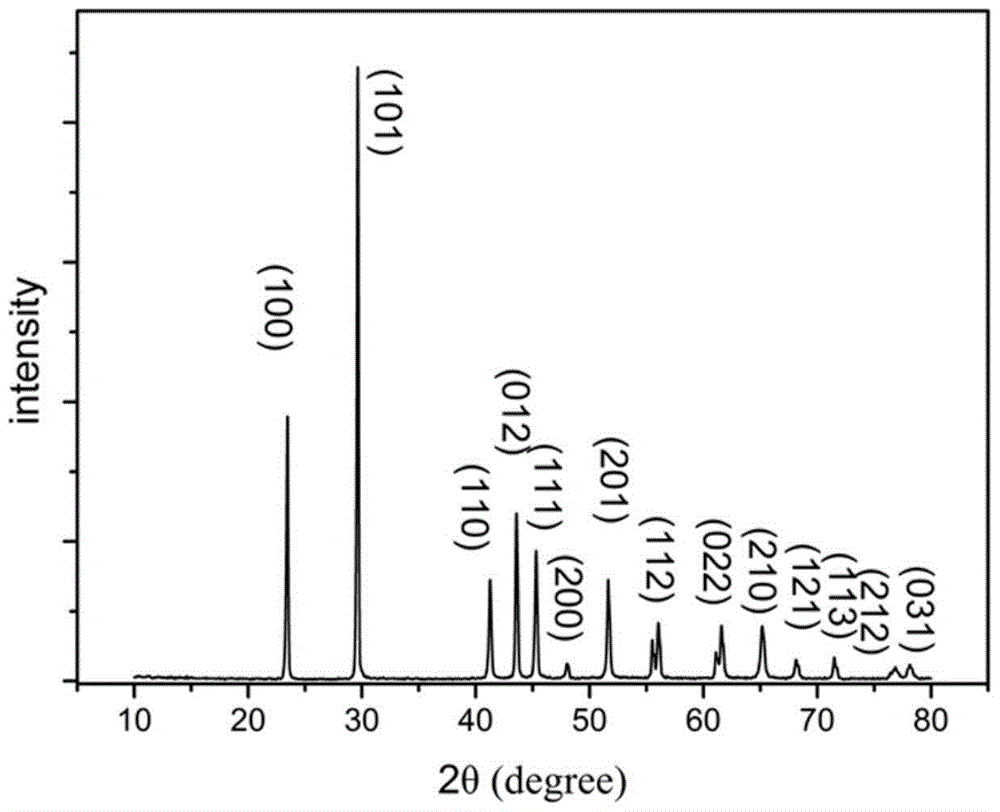

[0034] attached by figure 1 It can be seen that the prepared product is simple selenium with high purity.

[0035] attached by figure 2 It can be seen that the prepared black selenium is a spherical particle with a size between 500 nm and 10 μm.

[0036] 2. Test of the simulated activity of nano black selenium peroxidase:

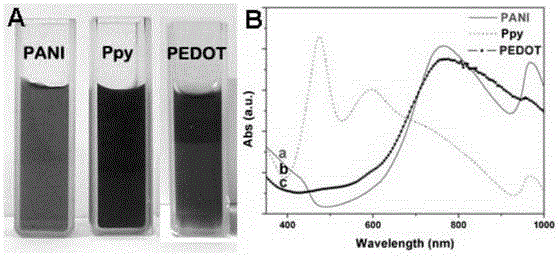

[0...

Embodiment 2

[0063] Weigh 0.111g selenium dioxide (SeO 2 ), dissolved in 5 mL of deionized water at room temperature, added 0.4 mL of concentrated sulfuric acid with a mass concentration of 98%, stirred for 5 minutes, added 30 mL of glycerol, continued to stir for 30 minutes, transferred the mixture to an autoclave, and reacted at 120 ° C After 10 hours, the product was centrifuged, and the centrifuged precipitate was washed three times with deionized water and ethanol respectively, and then vacuum-dried at 60° C. to obtain nano black selenium powder.

Embodiment 3

[0065] Weigh 0.022g selenium dioxide (SeO 2 ), dissolved in 7.5mL of deionized water at room temperature, added 0.08mL of concentrated sulfuric acid with a mass concentration of 98%, stirred for 5 minutes, added 30mL of glycerol, continued to stir for 30 minutes, transferred the mixture to an autoclave, and heated at 150°C After reacting for 8 hours, the product was centrifuged, and the centrifuged precipitate was washed three times with deionized water and ethanol respectively, and vacuum-dried at 60° C. to obtain nano black selenium powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com