High-superficial-area porous adsorption material and preparation method and application of high-superficial-area porous adsorption material

A porous adsorption material and high surface area technology, applied in chemical instruments and methods, adsorption water/sewage treatment, other chemical processes, etc., can solve the problems of high cost, unsatisfactory realization of the third step, etc., and achieve easy preparation and low density , large size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

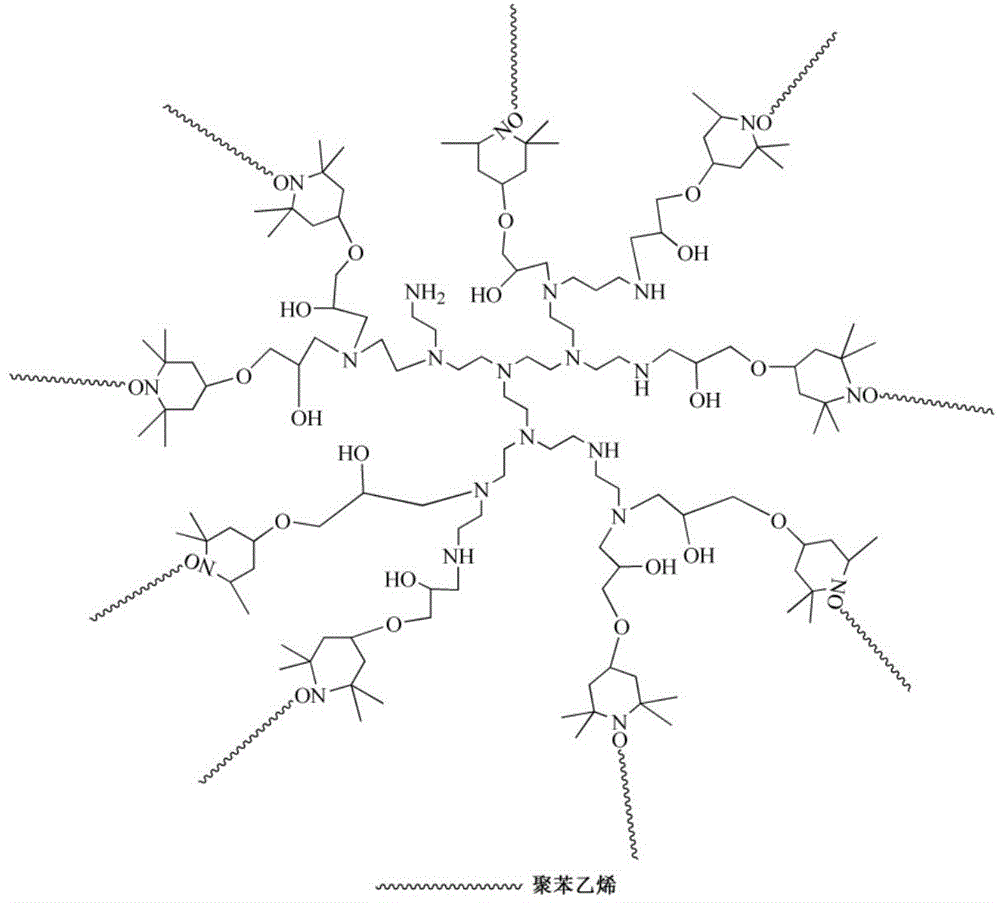

[0035] Glyceryl ether polystyrene alkylated PEI (referred to as PEIPS, the structure see figure 1 , figure 1 In , PEI has an average of 232 repeating units, only a few are drawn for clarity) as a stabilizer. Among them, 30% of the amino hydrogen of PEI (product of Aldrich Company, molecular weight 10000) is alkylated by glyceryl ether polystyrene (PS, molecular weight 1900). The compound was synthesized according to literature (Wan DC, Yuan JJ, Pu HT. Macromolecules 2009, 42, 1533).

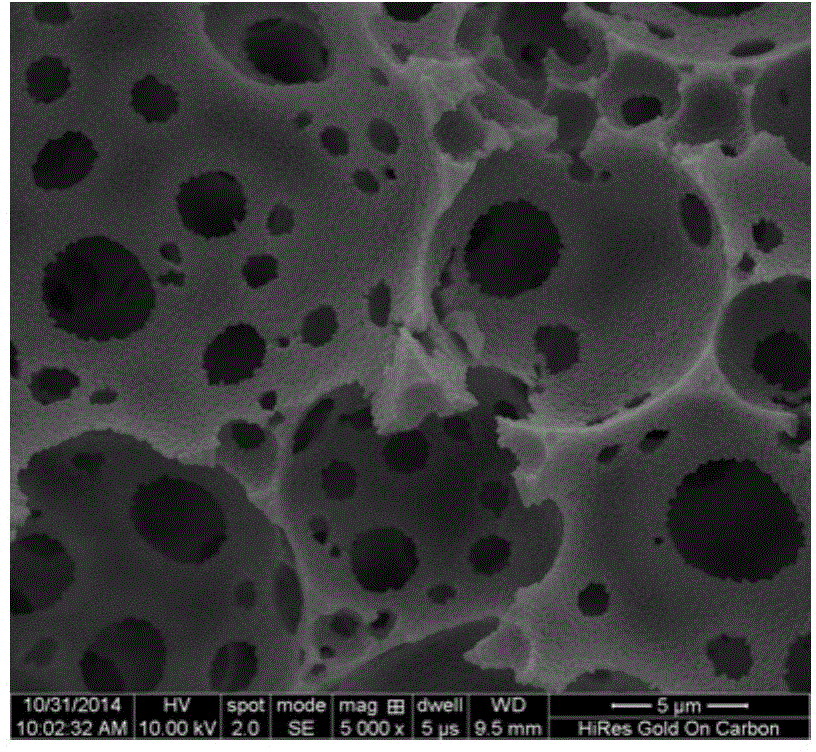

[0036] The oil phase is composed of styrene St, divinylbenzene DVB, toluene, AIBN initiator and PEIPS, and the specific composition is: St / DVB: 60% (St / DVB=8:2), toluene: 30%, PEIPS: 10% ; AIBN: 1% of the mass of the oil phase. Another 9 times the volume of water (composed of phosphate buffer (0.01M) solution, pH 7.4) was taken, and the water phase was dropped into the oil phase under vigorous stirring of the oil phase. Stirring was continued for several minutes after the drop was complete, a...

Embodiment 2

[0038] The PEI amphiphile as a stabilizer was prepared by the reaction of PEI and 1,2-epoxy-9-decene. PEI (1 gram, product of Aldrich Company, molecular weight 10000) and 1,2-epoxy-9-decene (2.5 grams) were stirred in chloroform for 30 hours, and the chloroform was distilled off to obtain a highly viscous liquid. Similar to Example 1, the high-viscosity amphiphile is used instead of PEIPS, and a porous high-surface material can be obtained similarly.

Embodiment 3

[0039] Embodiment 3: the purification treatment of the wastewater containing anionic dye

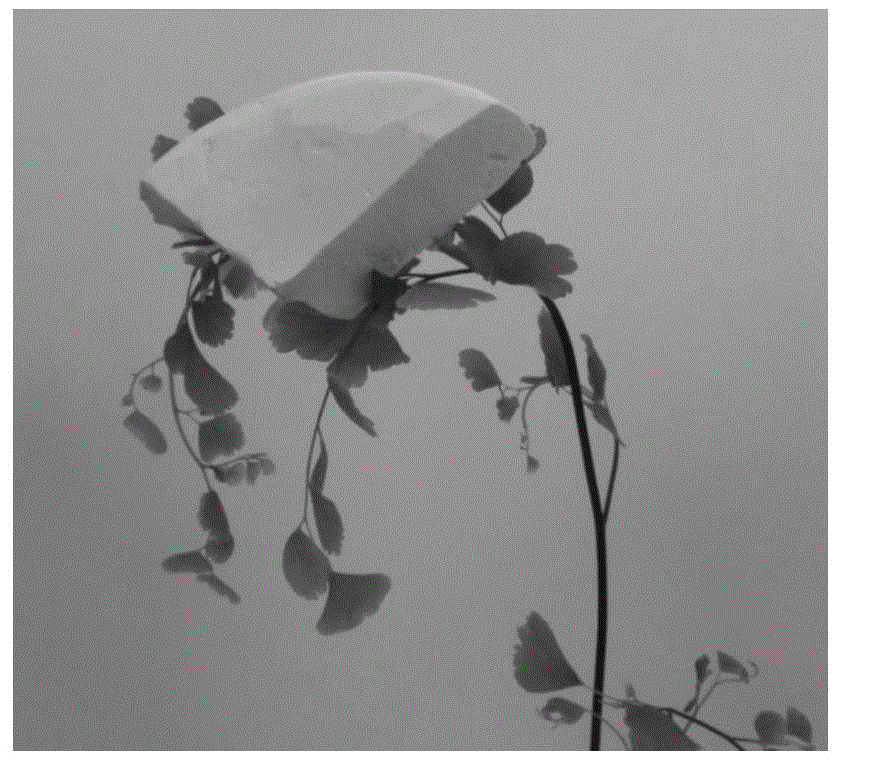

[0040]Taking the anionic dye methyl orange as an example, make it into a concentration of 2.5×10 -5 M solution (6 milliliters, UV absorbance is about 1), add a small piece of porous material (0.2 gram) that embodiment 1 makes, after standing for 2 days, utilize UV-Vis spectrometry to measure residual absorbance (if necessary, water phase Concentrated and then determined). According to the Lambert-Beer law and the molar absorptivity of the dye, the test shows that the residual concentration of methyl orange in water is 1.5×10 -7 M. Cutting the adsorbent, it can be found that the color of the adsorbent gradually becomes lighter from the outside to the inside, indicating that the material is open-pored. Cutting the adsorbent into small pieces can speed up the adsorption process to some extent. Adsorption treatment was similarly performed on Rose Red RB, Potato Red EB, Eosin EY, Bromophe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com