A kind of face cream with anti-aging effect and preparation method thereof

An anti-aging and efficacy technology, applied in skin care preparations, pharmaceutical formulations, cosmetic preparations, etc., can solve the problems of unsatisfactory anti-aging effects, achieve strong film-forming and moisture absorption capabilities, easy skin absorption, and good The effect of scavenging free radicals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

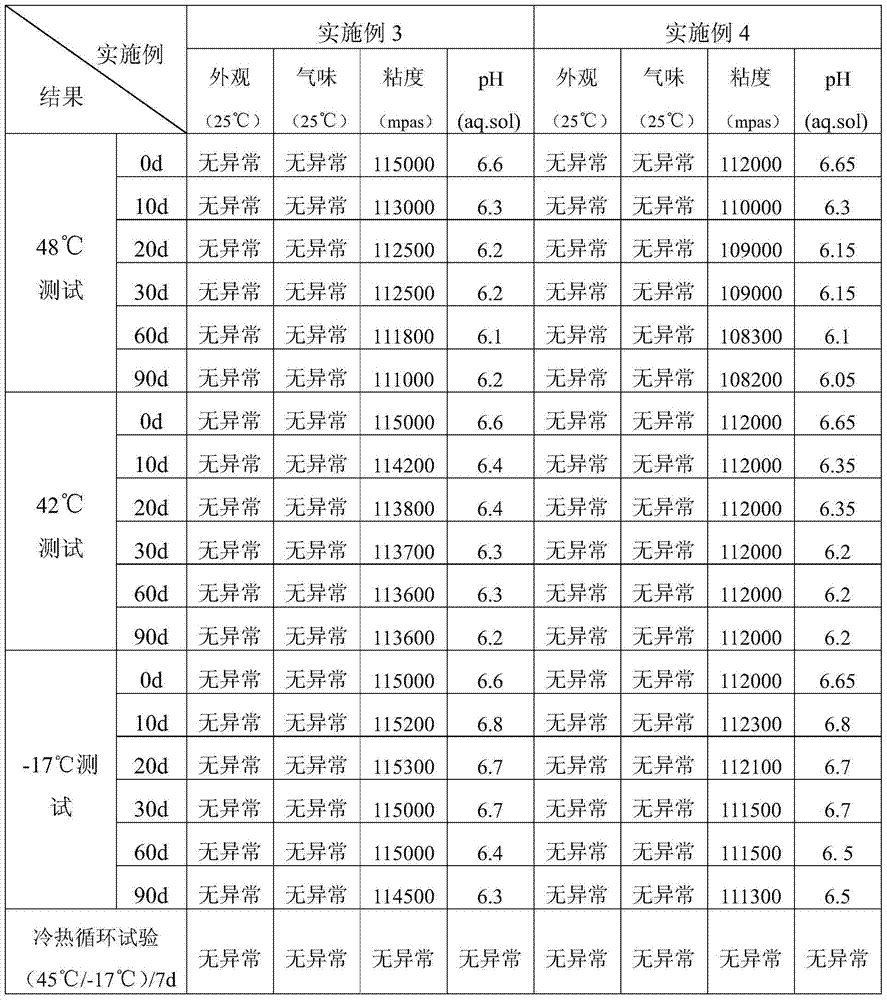

Examples

preparation example Construction

[0042] The preparation method of the above-mentioned compound plant anti-aging agent is as follows: after each extract is weighed according to the mass ratio, the mixture is uniformly mixed.

[0043] The INCI name of the Carbo resin is: acrylic (ester) / C10-30 alkanol acrylate cross-linked polymer, product model: Nuoyu Carbopol ETD 2020, manufacturer: Lubrizol Corporation of the United States.

Embodiment 1

[0045] (1) Under 1200rpm / min homogenization, slowly sprinkle 0.03 parts by mass of xanthan gum, 0.08 parts by mass of allantoin, 0.18 parts by mass of carbo resin, and 0.02 parts by mass of sodium hyaluronate into 50.03 parts by mass. Part of cold deionized water, turn off homogenization, turn on 300rpm / min stirring, heat up to 60℃, homogenize at 1200rpm / min for 10min, until the material is completely dispersed;

[0046] (2) Add 0.08 parts by mass of methyl paraben, 3.5 parts by mass of glycerin, and 2.5 parts by mass of 1,3-butanediol to the material obtained in step (1); continue heating to 82°C, -0.05 Homogenize under MPa vacuum at 1200rpm / min for 2~5min, keep heat for 15min under the same vacuum to defoam;

[0047] (3) 1.8 parts by mass of cetearyl glucoside, 1.8 parts by mass of glyceryl monostearate, and 0.3 parts by mass of C 20-22 Alkyl phosphate, 1.2 parts by mass of C16 / 18 alcohol, 1.8 parts by mass of cyclopentadimethylsiloxane, 2.8 parts by mass of hydrogenated polyisob...

Embodiment 2

[0056] (1) Under 1500rpm / min homogenization, slowly sprinkle 0.07 parts by mass of xanthan gum, 0.12 parts by mass of allantoin, 0.22 parts by mass of carbo resin, and 0.04 parts by mass of sodium hyaluronate into 64.76 parts by mass. Part of cold deionized water, turn off homogenization, turn on 500rpm / min stirring, heat up to 65℃, homogenize at 1500rpm / min for 15min, until the material is completely dispersed;

[0057] (2) Add 0.12 parts by mass of methyl parahydroxybenzoate, 4.5 parts by mass of glycerin, and 3.5 parts by mass of 1,3-butanediol to the material obtained in step (1); continue heating to 85°C, -0.1 Homogenize at 1500rpm / min for 5min under MPa vacuum, and keep for 20min under the same vacuum to defoam;

[0058] (3) Combine 2.2 parts by mass of cetearyl glucoside, 2.4 parts by mass of glyceryl monostearate, and 0.8 parts by mass of C 20-22 Alkyl phosphate, 1.8 parts by mass of C16 / 18 alcohol, 2.2 parts by mass of cyclopentadimethylsiloxane, 3.2 parts by mass of hydro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com