Efficient probiotics microcapsule as well as preparation method and application thereof

A microcapsule, high-efficiency technology, applied in applications, animal feed, animal feed, etc., can solve problems such as the influence of probiotic survival rate, and achieve the effects of improving tolerance, increasing the number of viable bacteria, and reducing losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

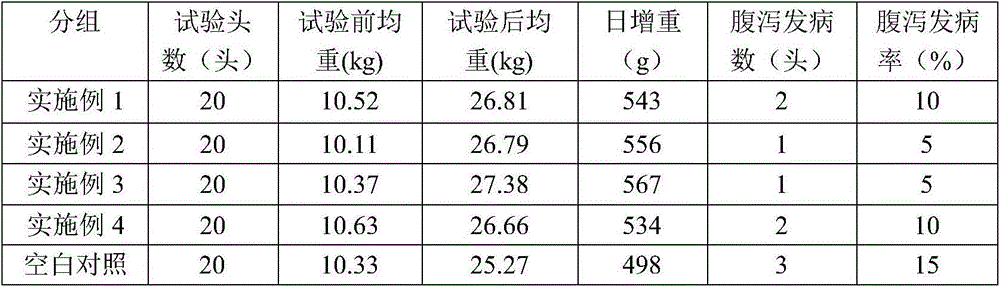

Examples

Embodiment 1

[0018] Example 1 Preparation of Saccharomyces cerevisiae microcapsules.

[0019] Saccharomyces cerevisiae seed solution was inoculated on the culture medium at an inoculation amount of 3wt%, cultivated at 37°C and 120r / min for 16h, centrifuged at 6000r / min for 5 minutes, and added 2wt% of porous starch and 10% of Skimmed milk powder, mixed with a high-speed homogenizer to obtain the core material; weigh sodium alginate and add it to distilled water to prepare a 3wt% sodium alginate aqueous solution, autoclave to obtain the first layer of wall material, and add the core material after cooling to room temperature. Mix well, the volume ratio of core material and wall material is 1:2, pass through Equl microcapsule generator, and add 8g / l CaCl dropwise 2 , solidified for 40 min, and collected the microcapsules by filtration. The microcapsules were suspended in distilled water at a concentration of 10 wt%. It was fluidized spray embedded with 5 wt% gelatin. The parameters are th...

Embodiment 2

[0020] Example 2 Preparation of Lactobacillus acidophilus microcapsules.

[0021] Inoculate the seed solution of Lactobacillus acidophilus in the culture medium at an inoculum amount of 3wt%, cultivate at 37°C and 120r / min for 14h, centrifuge at 8000r / min for 5 minutes, and add porous starch accounting for 2% of the total weight of Lactobacillus acidophilus cell precipitation Mix with 10wt% skimmed milk powder with a high-speed homogenizer to obtain the core material; add 3wt% sodium alginate to distilled water and mix, autoclave to obtain the first layer of wall material, cool to room temperature, add the core material and mix well , the volume ratio of the core material to the wall material is 1:2, through the Equl microcapsule generator, and 8g / l CaCl is added dropwise 2 , solidified for 40 min, and collected the microcapsules by filtration. Suspend the microcapsules in distilled water at a concentration of 10 wt%. It was fluidized spray embedded with 5 wt% gelatin. The ...

Embodiment 3

[0022] Example 3 Preparation of Enterococcus faecium microcapsules.

[0023] Inoculate the seed solution of Enterococcus faecium on the culture medium at an inoculum amount of 3wt%, cultivate at 37°C and 120r / min for 14h, centrifuge at 8000r / min for 5 minutes, add porous starch and 10wt% of the total weight of Enterococcus faecium thallus % skimmed milk powder, mixed with a high-speed homogenizer to obtain the core material; weigh sodium alginate and add it to distilled water to prepare a 3wt% sodium alginate aqueous solution, and autoclave to obtain the first layer of wall material, and add the core material after cooling to room temperature Mix the material well, the volume ratio of the core material and the wall material is 1:2, pass through the Equl microcapsule generator, and add 8g / l CaCl dropwise 2 , solidified for 40 min, and collected the microcapsules by filtration. The microcapsules were suspended in distilled water at a concentration of 10 wt%. It was fluidized s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com