grain seeder

A seeder and grain technology, which is applied in the field of millet seeder, can solve the problems of long profiling distance, poor uniformity, and low reliability, and achieve the effects of small secondary disturbance, saving seeds, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to enable those skilled in the art to better understand the present invention, the present invention will be further clearly and completely described below in conjunction with the accompanying drawings.

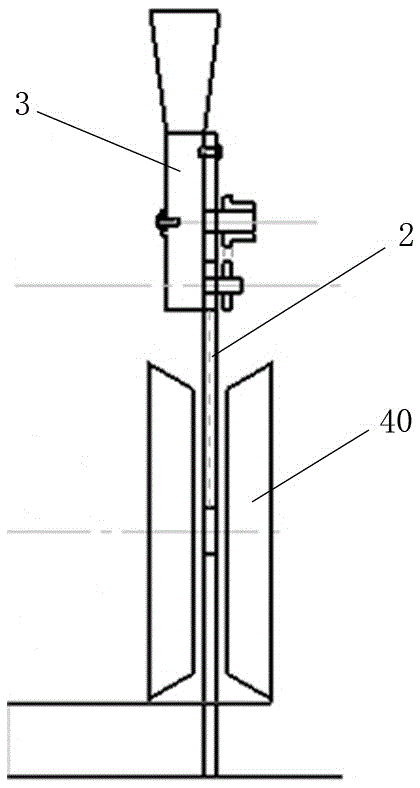

[0019] figure 1 The grain seeder shown includes a frame 1 and one or more individual sowing groups connected with one frame 1 .

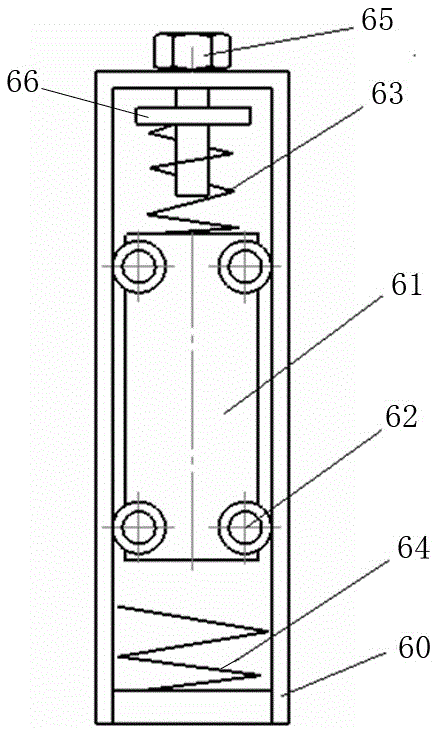

[0020] The single sowing group includes: single steel frame 2, seed meter assembly 3, suppression mechanism 4, sheath type seeder 5 and slider profiling structure 6, and the seed meter assembly 3 is fixed on the single steel frame 2 The top and the bottom of the seed meter assembly 3 are connected with the seed pipe 7, the suppression mechanism 4 is fixed on the bottom of the single steel frame 2, the suppression mechanism 4 and the seed meter assembly 3 are connected by a chain transmission mechanism 8, and the sheath seeder 5 Be fixed on seed pipe 7 bottoms.

[0021] The seed metering device assembly adopts a wheeled millet seed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com