Negative electrode material for lithium ion secondary battery, method for producing same, negative electrode for lithium ion secondary battery using same, and lithium ion secondary battery

A secondary battery and negative electrode material technology, applied in the direction of secondary batteries, battery electrodes, non-aqueous electrolyte battery electrodes, etc., can solve the problems that the cycle characteristics of the practical level cannot be obtained, and the expansion of metal materials cannot be fully alleviated, and achieve excellent Effects of initial charge and discharge efficiency, high discharge capacity, and moderate swelling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0110] [Production of negative electrode material]

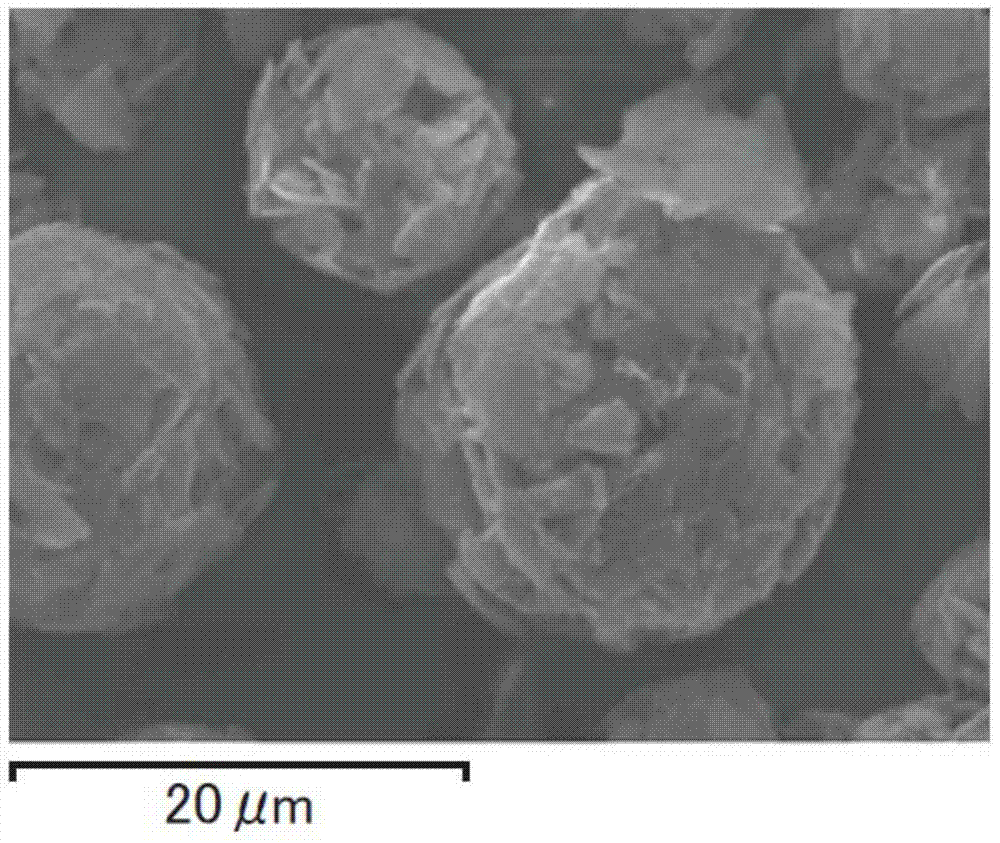

[0111] Scaly graphite particles with an average particle size of 5 μm and an average flatness of 20 and silicon particles with an average particle size of 0.2 μm were dispersed in an aqueous polyacrylic acid solution, and spray-dried by a spray drying device to obtain a spherical composite precursor. Next, using a planetary mixer, a tar-in-oil solution of coal tar pitch was added to the composite precursor and kneaded, and then calcined at 1000°C in an inert atmosphere of nitrogen to obtain a negative electrode as the target composite. Material. With respect to the compounding quantity of each raw material, as shown in Table 1, the respective abundance ratio in the complex which is a final product was adjusted. Spray drying was performed under the conditions shown in Table 2. The average particle diameter of the complex measured by a laser particle size distribution analyzer was 10 μm. The average aspect ratio of the comp...

Embodiment 2

[0137] Preparation of a composite, preparation of a negative electrode and an evaluation battery, and evaluation of battery characteristics were performed in the same manner as in Example 1, except that the compounding ratio when preparing the composite was adjusted as shown in Tables 1 and 2.

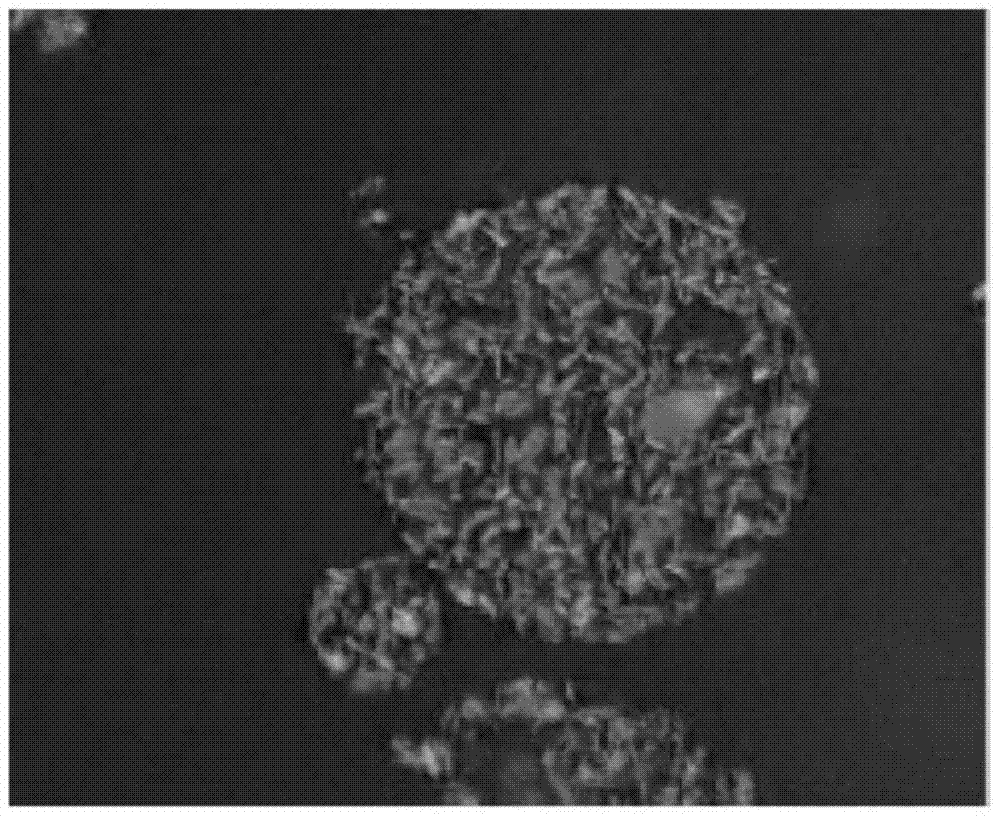

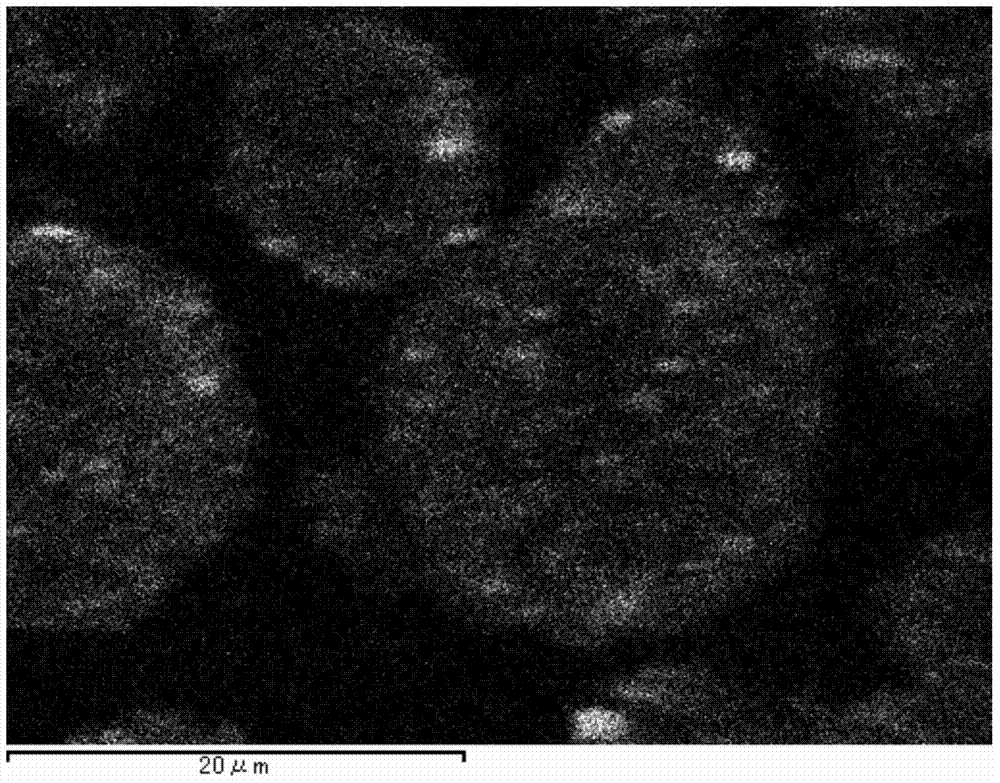

[0138] From the SEM image of the composite, it can be seen that the scaly graphite particles are oriented concentrically on the surface, and from the polarized light microscope image of the cross section of the composite, it can be seen that there are voids inside, and the scaly graphite particles are non-parallel to each other. . In addition, from the EDX mapping image, it can be seen that silicon particles exist dispersedly.

Embodiment 3、4

[0140] In the ratio shown in Table 1, flake graphite particles with an average particle size of 5 μm and an average flatness of 20, silicon particles with an average particle size of 0.2 μm, and graphite fibers were added to an aqueous polyacrylic acid solution and mixed. In the same manner as in Example 1, preparation of a composite, preparation of a negative electrode and an evaluation battery, and evaluation of battery characteristics were performed.

[0141] From the SEM image of the composite, it can be seen that the scaly graphite particles are oriented concentrically on the surface, and from the polarized light microscope image of the cross section of the composite, it can be seen that there are voids inside, and the scaly graphite particles are non-parallel to each other. . In addition, from the EDX mapping image, it can be seen that silicon particles exist in a dispersed manner. It can also be seen from the appearance of the composite and the SEM image of the cross s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com