Method for processing rolled stock in a rolling mill

A technology of rolling mill and rolling stock, applied in the field of processing rolling stock in rolling mill, can solve the problems of knotting of wire rod rolling stock, asynchronous driving device or rolling speed, and rolling stock quality can no longer meet the requirements, etc. Realize the effect of dynamic correction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

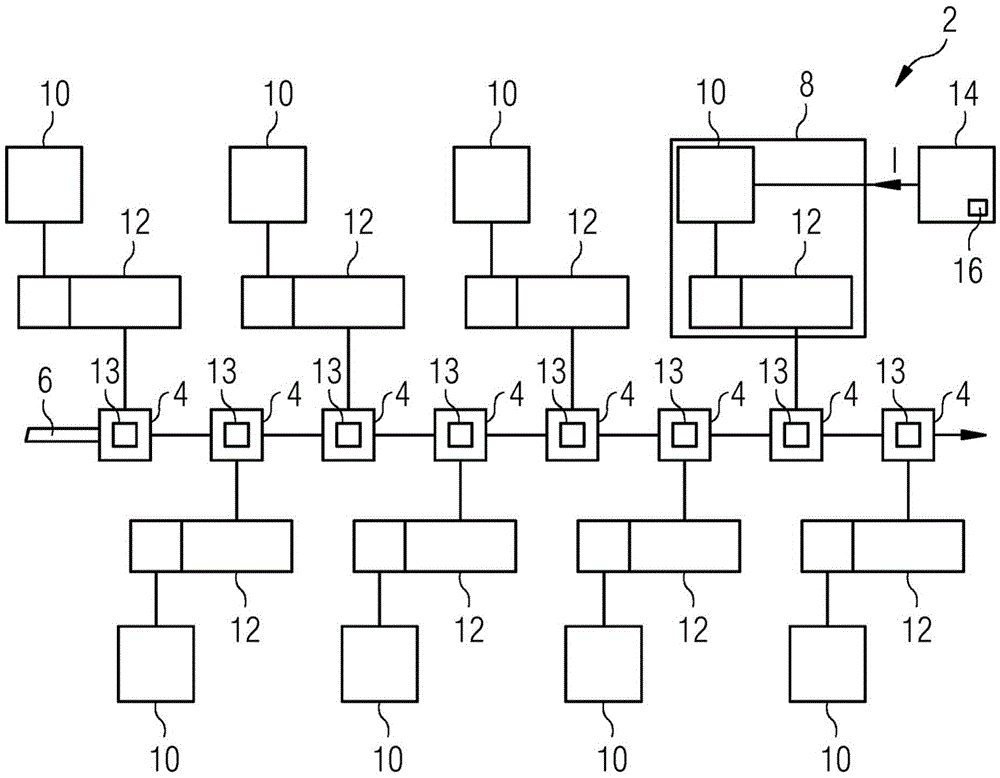

[0024] figure 1 A cross-sectional view of a rolling train 2 with rolling stands 4 arranged one behind the other is shown, wherein the rolling stands are used for processing a rolling stock 6 . exist figure 1 8 schematically shows eight rolling stands 4 arranged one behind the other, through which a rolling stock 6 passes, for example a bar as rolling stock is rolled into a wire rod.

[0025] Each rolling stand 4 is assigned a separate drive 8 comprising an electric motor 10 and a gear 12 , only the drive 8 being shown in the drawing for the sake of clarity. The drive is supplied with the desired current I by means of a rectifier 14 with a control unit 16 . Each rolling stand 4 also includes at least one roll 13 , which is driven by a corresponding drive 8 at a preset speed n, which is taken from a pass table, for example.

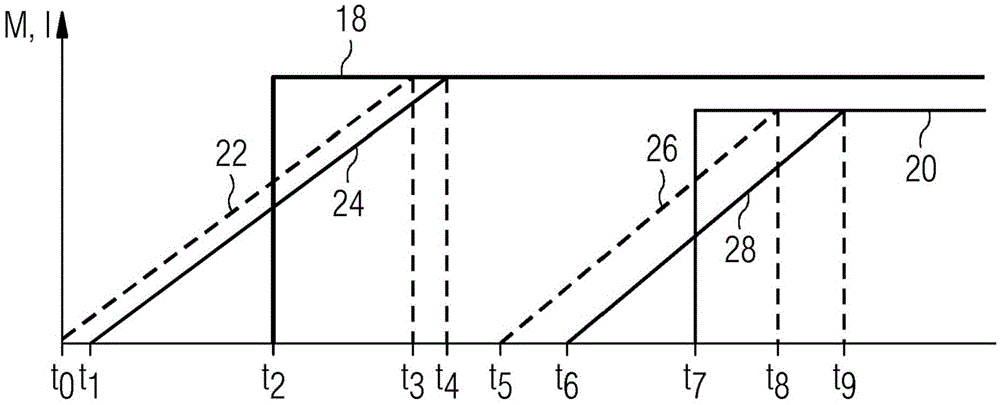

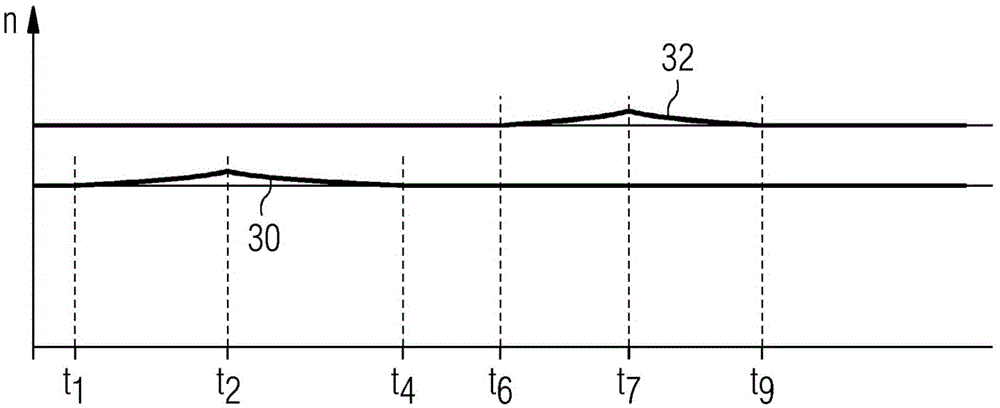

[0026] If the rolling stock 6 is placed on the rolls 4 of the rolling stand 13, a load moment M is applied to the drive 8 of the corresponding rolling s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com