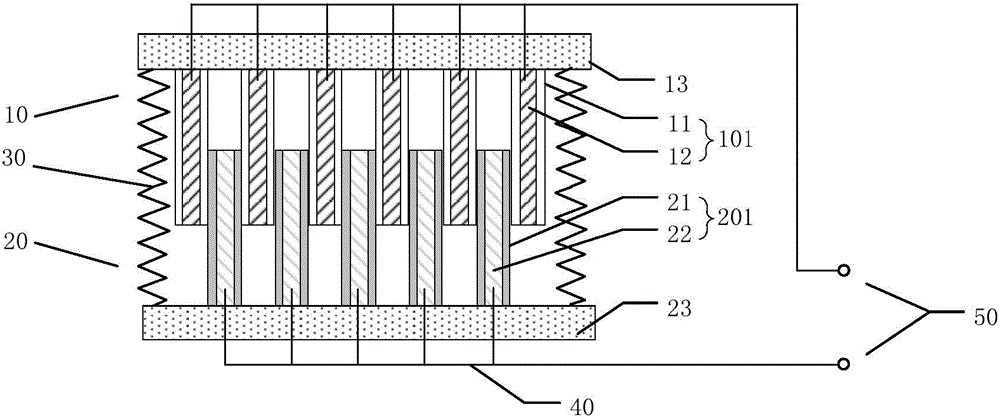

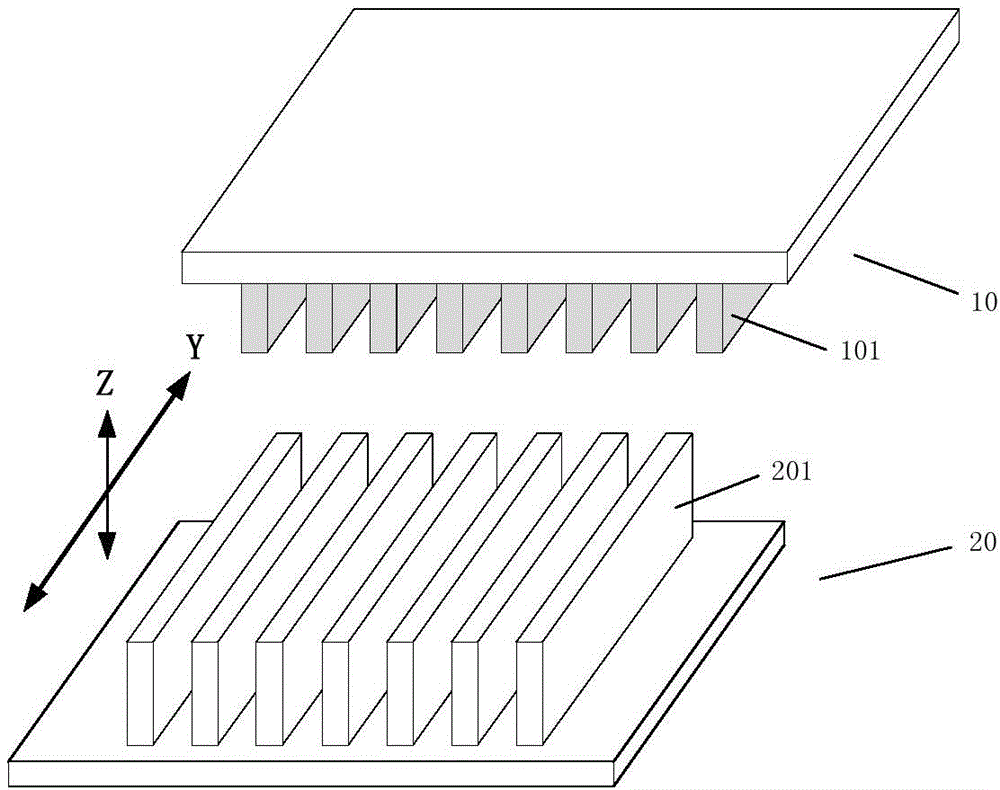

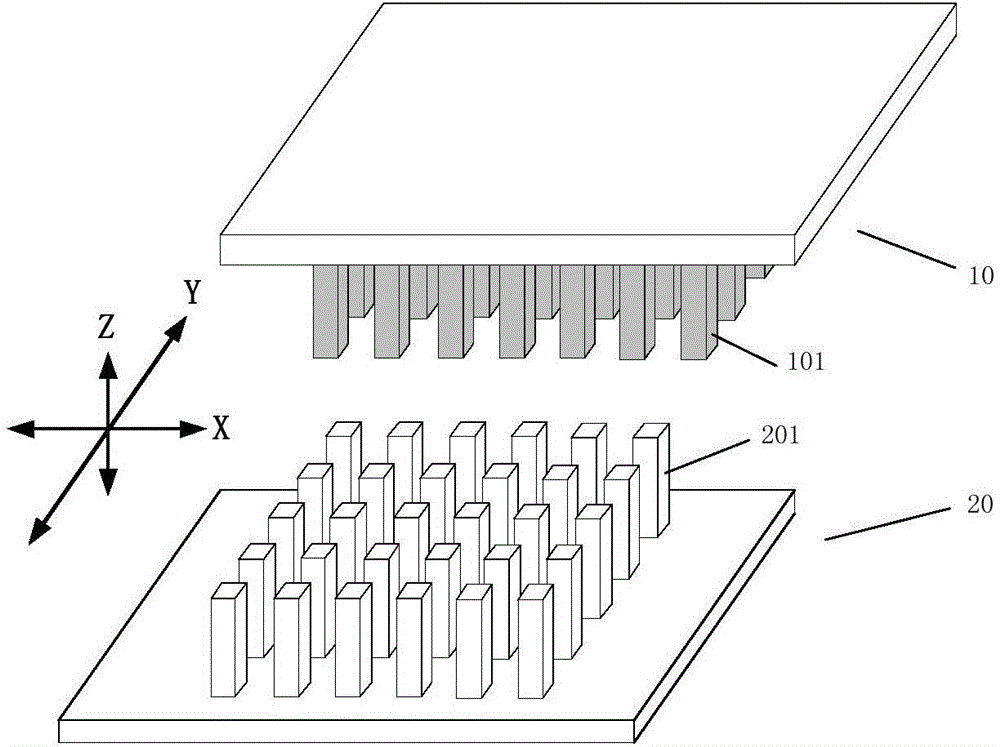

Friction nanometer power generator with gear shaping structure

A technology of nano generators and generators, applied in the direction of friction generators, etc., to achieve the effects of solving insufficient contact, increasing friction area, and improving output performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0068]A sheet-like polyimide (Kapton) film is used as the first friction layer 11 , and a layer of copper film is deposited on its surface as the first electrode 21 to form a composite sheet of the friction layer and the electrode. By folding the film, the composite sheet is formed into a tooth-shaped first friction unit and fixed on the base made of copper-plated polymethyl methacrylate (PMMA) plate, so that the Kapton film becomes the core of the first friction unit. Outer surface; the first electrode is located at the center of each tooth structure after extrusion molding, and its fixed end that is in contact with the copper-plated side of the PMMA substrate is connected to the copper conductive thin layer with each other, thus completing the first component preparation. The second component is prepared in the same way, the only difference is that the second friction layer 21 and the second electrode 22 use the same material—aluminum foil. Therefore, it is only necessary t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com