TFET (Tunneling Field Effect Transistor) and forming method thereof

A tunneling field effect and transistor technology, which is applied in the fields of semiconductor devices, semiconductor/solid-state device manufacturing, electrical components, etc. The effect of increasing the current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0077] This embodiment provides a method for forming a tunneling field effect transistor, including:

[0078] refer to figure 2 , providing a substrate 110 .

[0079] The substrate 110 may be a silicon substrate, a silicon germanium substrate or other semiconductor substrates known in the art.

[0080] In this embodiment, the substrate 110 is not doped.

[0081] In other embodiments, the second type of doping can be performed on the bottom of the substrate 110 first, and a deep doped well is formed at the bottom of the substrate 110; then, the first type of doping is performed on the substrate 110 above the deep doped well. impurity, forming the first type doped well. The first type of doping and the second type of doping are different.

[0082] The purpose of forming deep doped wells and first type doped wells is to avoid latch-up and other reliability problems.

[0083] In this embodiment, the first type of doping is p-type, and the second type of doping is n-type.

...

no. 2 example

[0152] The difference between this embodiment and the first embodiment is:

[0153] refer to Figure 9 , after forming the source 161, on the upper surface of the substrate 110, the gate structure, the channel fin 130 and the source 161, and the gate structure, the underlying fin 120, the channel fin 130 and the source 161 The sidewalls form a mask layer having a window exposing the channel fin 130 and the underlying fin 120 on the other side of the gate structure;

[0154] performing heavily doped ion implantation on the channel fin 130 through the window to form a drain 162 in the channel fin 130;

[0155] removing the second patterned mask layer.

[0156] In other embodiments, the drain 162 may also be formed first, and then the source 161 is formed.

[0157] The method for forming the TFET is described above by taking the source 161 across the channel fin 130 on one side of the gate structure as an example.

[0158] In other embodiments, heavily doped ion implantation ...

no. 3 example

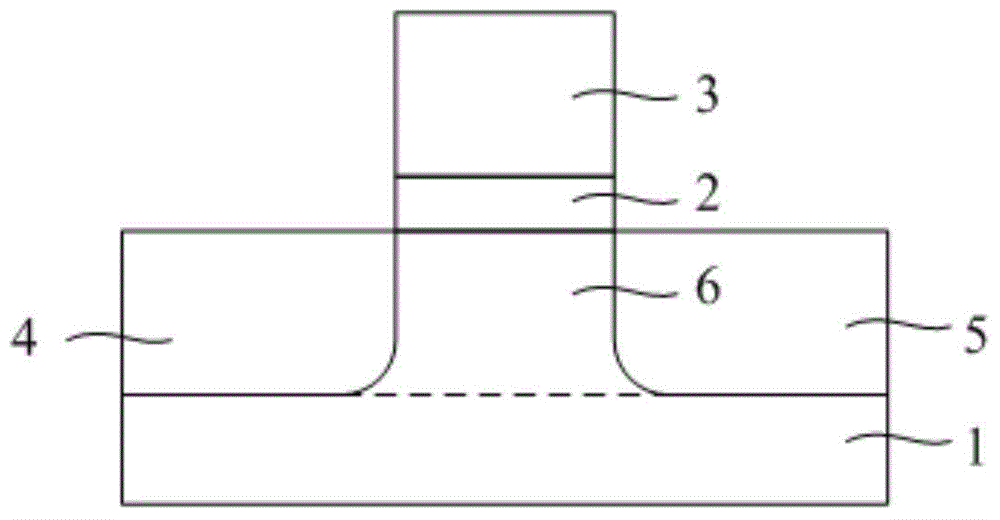

[0162] refer to Figure 8 , this embodiment provides a tunneling field effect transistor, including:

[0163] base 110;

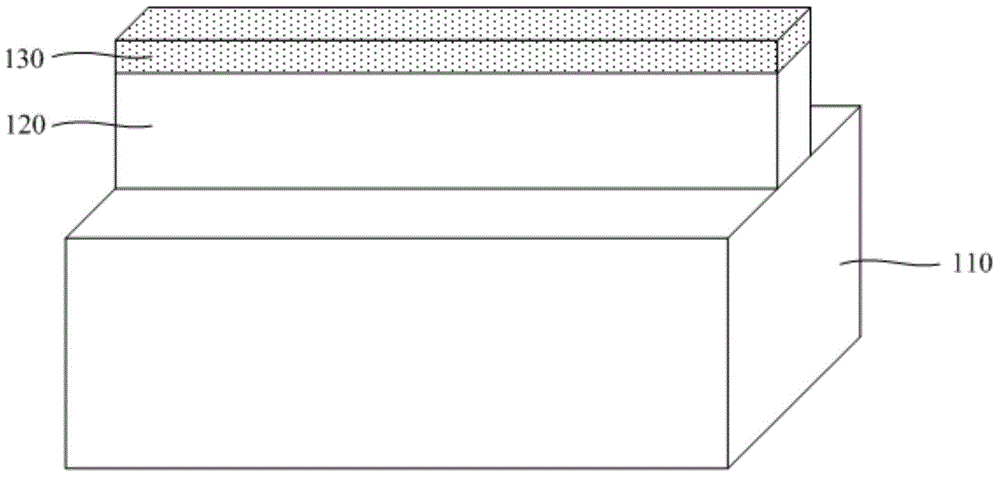

[0164] a bottom fin 120 on the substrate 110, the bottom fin 120 has a first type of doping;

[0165] The channel fin 130 located on the upper surface of the bottom fin 120, the channel fin 130 has a second type of doping, the second type of doping is different from the first type of doping, the channel fin 130 The electron mobility of is greater than the electron mobility of the bottom fin 120;

[0166] a gate structure spanning the channel fin;

[0167] a source 161 having a first type of doping;

[0168] The drain 162 has the second type of doping.

[0169] The source 161 straddles the channel fin 130 . In other embodiments, the source 161 may also be located in the channel fin 130 .

[0170] The drain 162 straddles the channel fin 130 . In other examples, refer to Figure 9 , the drain 162 may also be located in the channel fin 130 .

[0171] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com