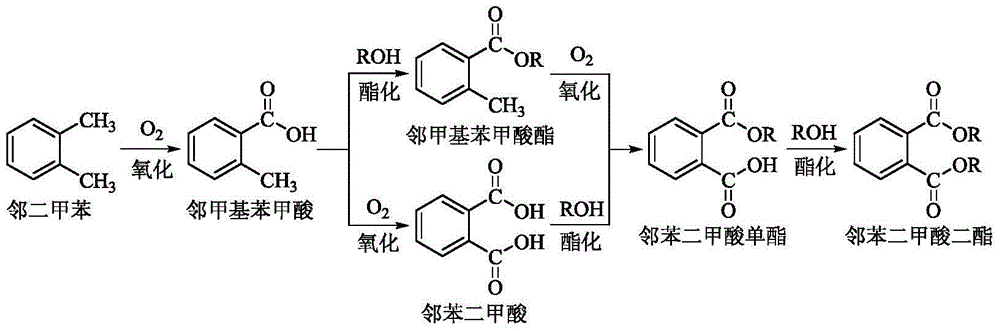

Method for preparation of diester phthalate by o-xylene liquid-phase oxidation and esterification coupling

A technology of phthalic acid diester and xylene liquid, which is applied in the field of preparing phthalic acid diester by coupling liquid-phase oxidation and esterification of o-xylene, which can solve the problems of raw material consumption, energy consumption, complicated operation, and poor safety. , achieve the effect of reducing energy consumption and simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

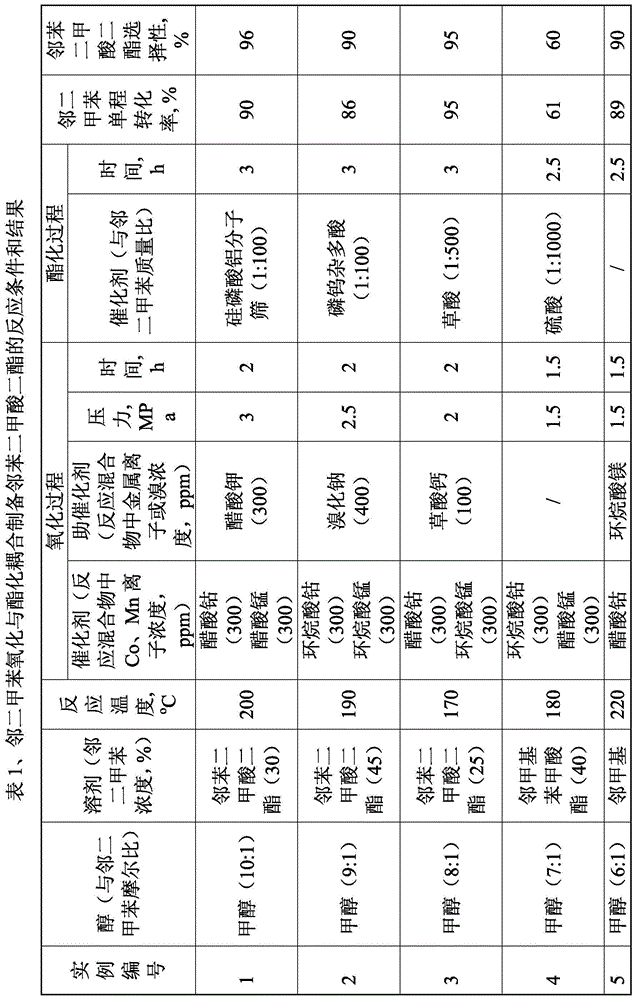

Embodiment 1

[0021] In the continuous reaction device, the mixture of o-xylene, dimethyl phthalate, manganese acetate, cobalt acetate, and potassium acetate is pumped into the oxidation reaction tube (the concentration of cobalt, manganese, and potassium ions in the reaction mixture are each 300ppm, The concentration of o-xylene is 30%), filled with 3MPa oxygen, oxidation occurs at 200°C, and the reaction residence time is 2h. The mixture of the oxidized mixture and methanol is pumped into the esterification reaction tube equipped with silicoaluminophosphate molecular sieve (the molar ratio of methanol to the starting o-xylene is 10:1, the mass ratio of the silicoaluminophosphate molecular sieve to the starting o-xylene 1:100), esterification occurs at 150°C, and the reaction residence time is 3h. After the esterification reaction, the mixture is pumped into the oxidation reaction tube to oxidize the second methyl group on the benzene ring, and then pumped into the esterification reaction ...

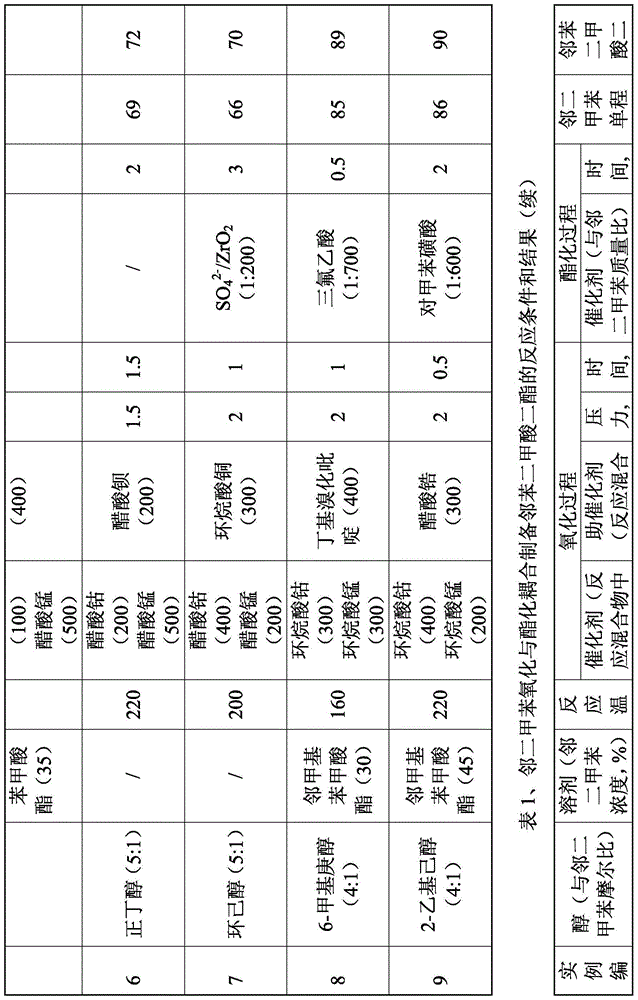

Embodiment 2~18

[0023] The specific method of Examples 2-18 is similar to that of Example 1, and the specific reaction conditions and results are listed in Table 1.

[0024] As can be seen from the above examples, using o-xylene and alcohol as raw materials, under the reaction conditions shown in Table 1, the coupling of liquid-phase oxidation and esterification is carried out, that is, the o-xylene is mainly oxidized to o-methyl Benzoic acid, after the esterification reaction, the second methyl group on the benzene ring is oxidized to a carboxyl group, and then the esterification reaction occurs, which can realize the process of converting o-xylene into dimethyl phthalate. The reaction temperature is 150-230°C. Compared with the gas-phase oxidation method, the reaction conditions are milder and the CO is greatly reduced. 2 Generation and discharge, low raw material consumption and energy consumption, good safety; intermediate products do not need to be separated and purified, the operation i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com