Cubic boron nitride sintering body cutting tool and manufacturing method of the same

A technology of cubic boron nitride and cutting tools, which is applied in the field of cubic boron nitride sintered cutting tools and its manufacturing, can solve the problems of low adhesion strength, easy chipping of the tool tip, shortened tool life, etc., and achieve improved wear resistance sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

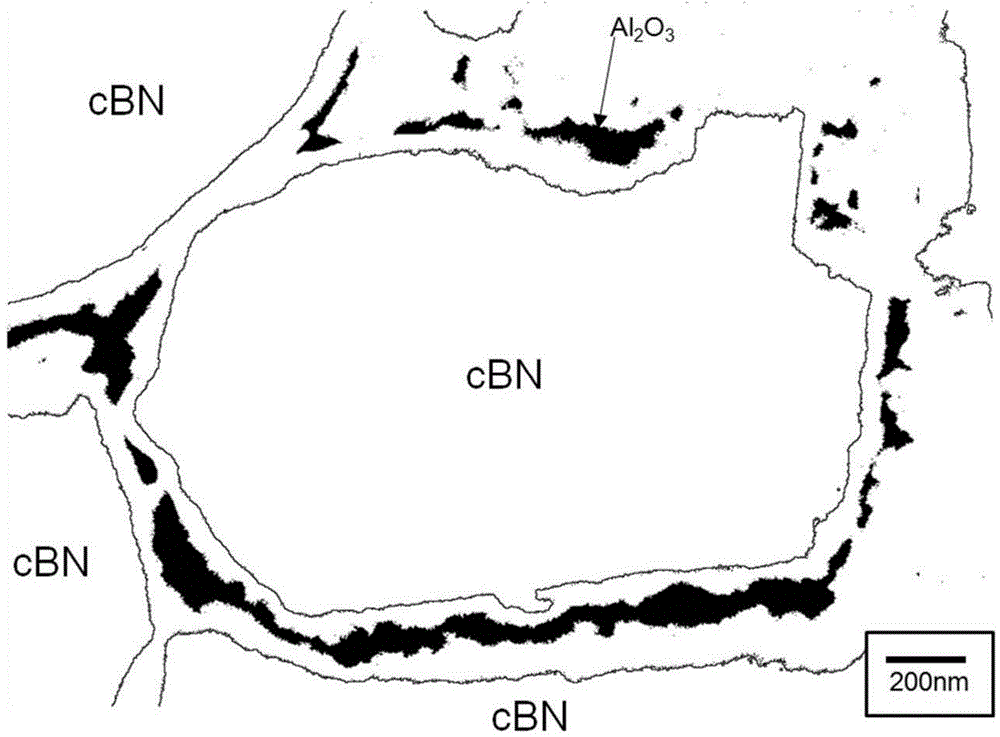

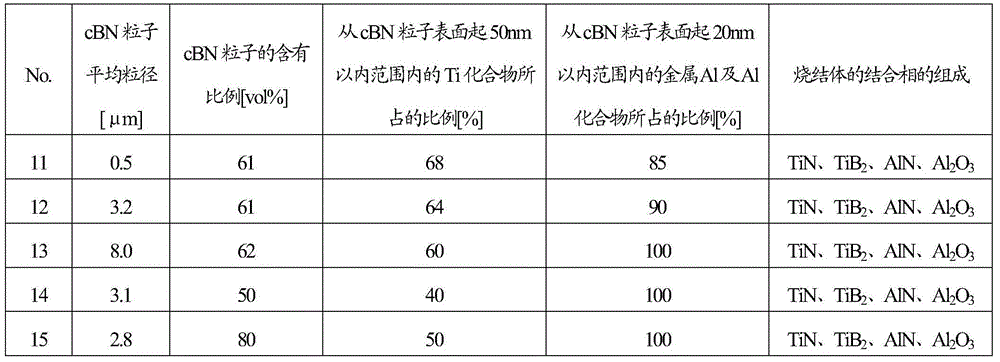

[0059] Production of cBN particles as raw material powder:

[0060] Using cBN particles with an average particle size of 0.5 to 8.0 μm as the substrate, the ALD method (Atomic Layer Deposition: which is to make the molecules of the raw material compound react layer by layer on the substrate in the vacuum chamber and repeat the process by Ar and nitrogen) The method of forming a film by purging the raw material compound is a kind of CVD method) It is coated with TiO to form a thin layer 2 Floor. More specifically, cBN particles with an average particle size of 0.5 to 8.0 μm are loaded into the furnace, and the temperature in the furnace is raised to 350° C., and Ti[N(CH 3 ) 2 ] 4 , and using H as the reactive gas 2 O, the following (1) to (4) is regarded as one cycle, and this cycle is repeated until the target layer thickness is reached, so that the surface of the cBN particle is coated with TiO with a predetermined layer thickness. 2 Floor.

[0061] (1)Ar+Ti[N(CH 3 ) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com