Apparatus for manufacturing three-dimensional objects

A technology for three-dimensional objects and equipment, applied in the directions of additive manufacturing, processing and manufacturing, and manufacturing tools, can solve problems such as uneven temperature distribution, and achieve the effect of implementing manufacturing processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

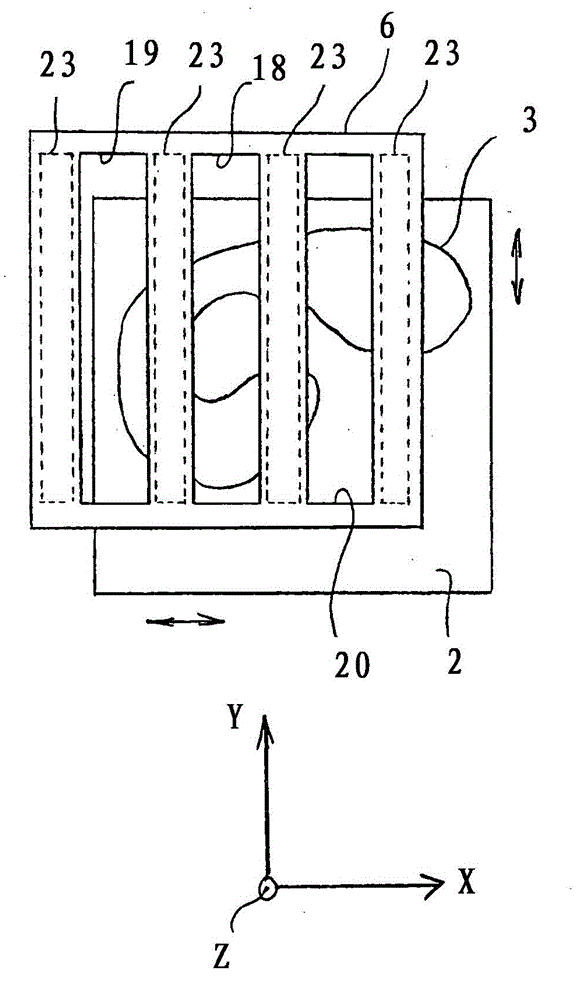

[0033] All figures do not show the invention to scale, but only schematically and only essential components thereof. In this case, the same reference numerals correspond to elements having the same function or a similar function.

[0034] according to figure 1 and 2 By way of example, a device 1 for laser sintering is described as a device for producing at least one three-dimensional object by selectively hardening a building material applied layer by layer. However, the present invention is not limited to this particular method. The present invention is also applicable to other lamination methods such as laser melting, mask sintering, drop-on-powder / dorp-on-bed, stereolithography or similar methods.

[0035] In the description of the present invention an orthogonal coordinate system (x, y, z) is used.

[0036] The device 1 for laser sintering comprises a build platform 2 arranged in the x-y plane, on which a three-dimensional object 3 is produced layer by layer in a known...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com