Silver tin mercury alloy particle and preparation technology thereof

A preparation process, amalgam technology, applied in coating and other directions, can solve problems such as increasing the difficulty and complexity of the process, affecting the purity of the amalgam, affecting the quality of the amalgam, achieving accurate and reliable mercury content, eliminating secondary pollution, shortening The effect of the production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] The silver-tin amalgam is mixed according to the weight ratio Ag:Sn:Hg=2:48:50 to prepare silver-tin amalgam particles with an average weight of 1.5 mg.

[0055] The preparation method of silver-tin amalgam particles:

[0056] 1) Under an argon atmosphere, add raw materials: 0.2Kg of silver powder, 4.8Kg of tin particles and 5Kg of liquid mercury into a closed container, heat up to 380°C to melt the raw materials, and mix under a pressure of 20psi for 1.5 hours until the mixture is uniform The alloy solution is obtained; in an inert gas atmosphere, by applying pressure, the pressure is controlled at 55psi, the alloy solution is pressed out, and the alloy liquid droplets are formed through the vibrating nozzle, and the frequency and amplitude are controlled at 600Hz and 0.3mm respectively, and the alloy solution is made into an alloy Liquid droplets, the diameter of alloy droplets is 0.65-0.75mm;

[0057] 2) indirectly cooling the inert gas flow with liquid nitrogen, an...

Embodiment 2

[0067] The silver-tin amalgam is proportioned by weight Ag:Sn:Hg=6:40:54 to prepare silver-tin amalgam particles with an average weight of 3 mg.

[0068] The preparation method of silver-tin amalgam particles:

[0069] 1) Under an argon atmosphere, add raw materials: 0.6Kg of silver powder, 4Kg of tin particles and 5.4Kg of liquid mercury into a closed container, heat up to 350°C to melt the raw materials, and mix under a pressure of 20psi for 1.5 hours until uniform The alloy solution is obtained; in an inert gas atmosphere, by applying pressure, the pressure is controlled at 55psi, the alloy solution is pressed out, and the alloy liquid droplets are formed through the vibrating nozzle, and the frequency and amplitude are controlled at 600Hz and 0.3mm respectively, and the alloy solution is made into an alloy Liquid droplets, the diameter of the alloy droplets is 0.8-0.9mm;

[0070] 2) indirectly cooling the inert gas flow with liquid nitrogen, and condensing the alloy dropl...

Embodiment 3

[0079] The preparation process is the same as that of the comparative example, except that the condensation temperature used is -140°C.

[0080] The following tests were carried out on the amalgam dripped at these three temperatures:

[0081] Forming condition: the amalgam may fall to the bottom and condense into large pieces due to insufficient coldness of the amalgam;

[0082] Degree of sticking: If the formed amalgam is very sticky, it will affect the subsequent powder coating and screening process, resulting in complicated powder coating and screening failure, and it may even affect the smooth infusion of amalgam for lamp manufacturers.

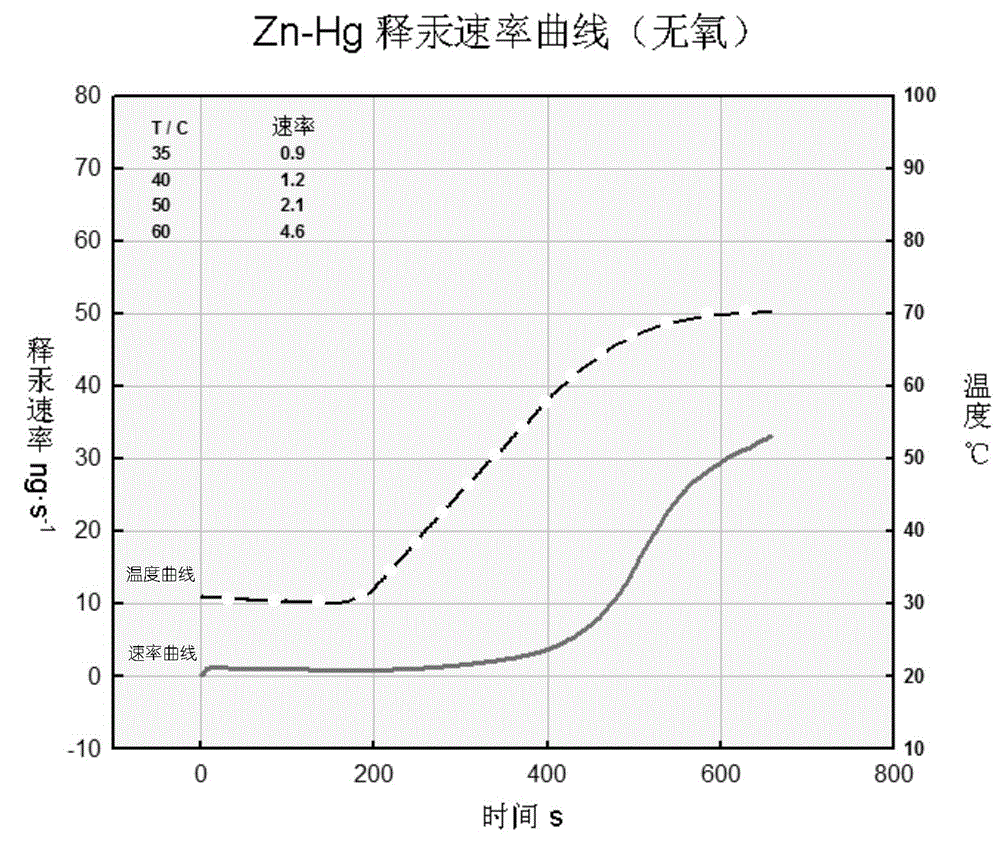

[0083] Mercury release characteristics: The speed of mercury release determines the time for the amalgam fluorescent lamp to reach the standard luminous flux within the specified time. The mercury is released quickly, and the luminous flux of the lamp rises quickly, which reflects the user experience of the end consumer. The test method ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com