Kitchen garbage treatment system and kitchen garbage treatment method

A kitchen waste and treatment system technology, which is applied in the fields of organic fertilizer, climate change adaptation, solid waste removal, etc. efficiency and other issues, to achieve the effect of automatic operation, simplification of sewage treatment, and reasonable equipment selection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In the present invention, the term "water" means a mixture mainly containing water, which may also include, for example, grease, waste residue and the like. In some cases herein, the term "water" and the term "liquid waste" have the same meaning, and the term "garbage" and the term "waste" have the same meaning.

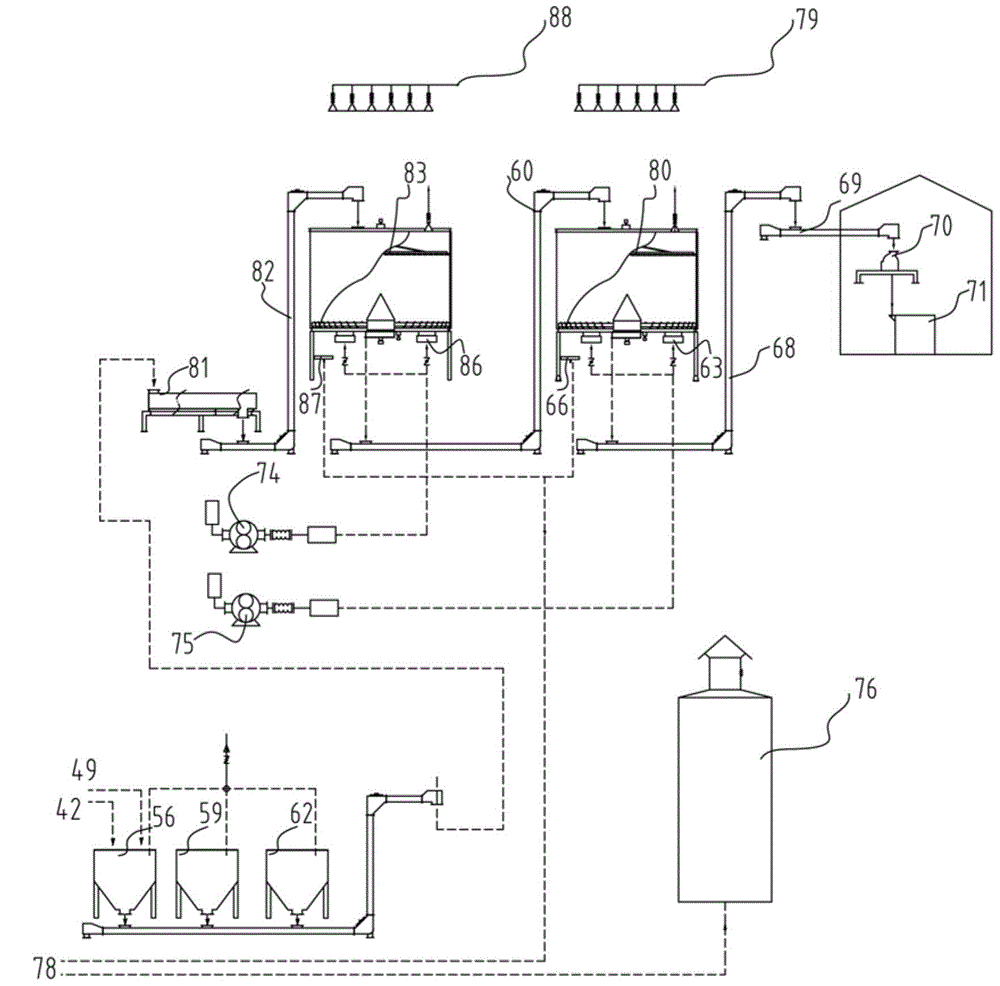

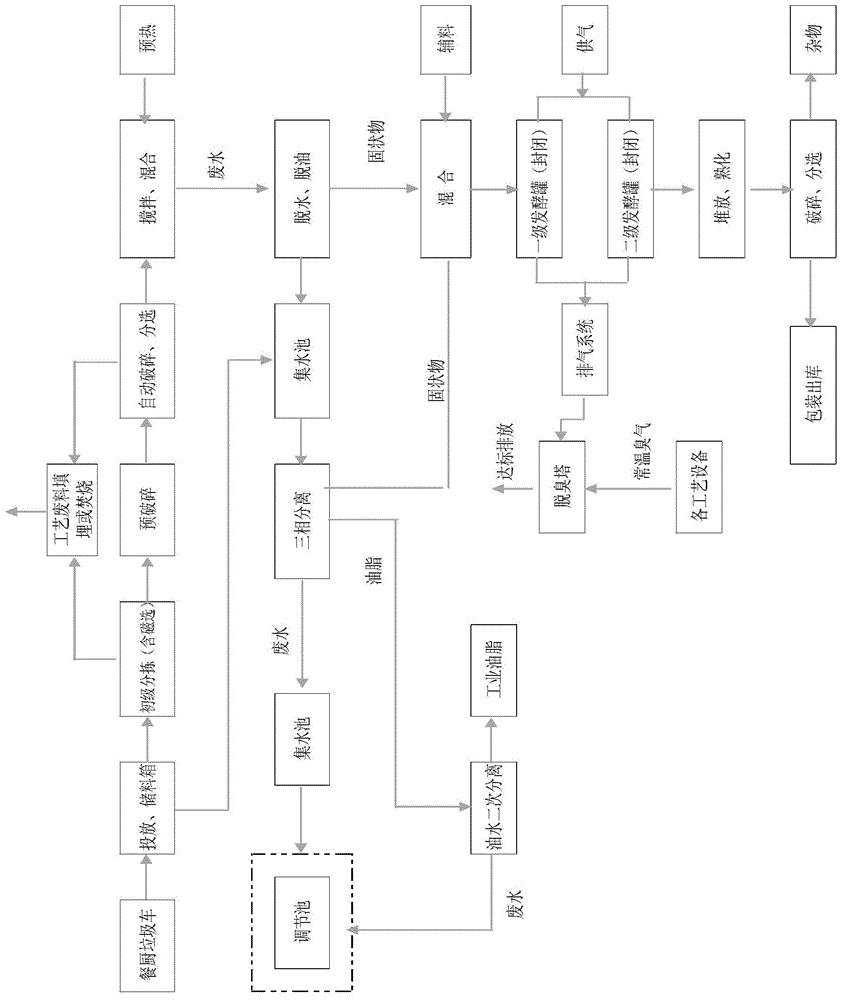

[0027] A food waste treatment system according to an embodiment of the present invention mainly includes a pretreatment subsystem, a fermentation subsystem and an auxiliary treatment subsystem. These subsystems cooperate with each other to complete the treatment of kitchen waste.

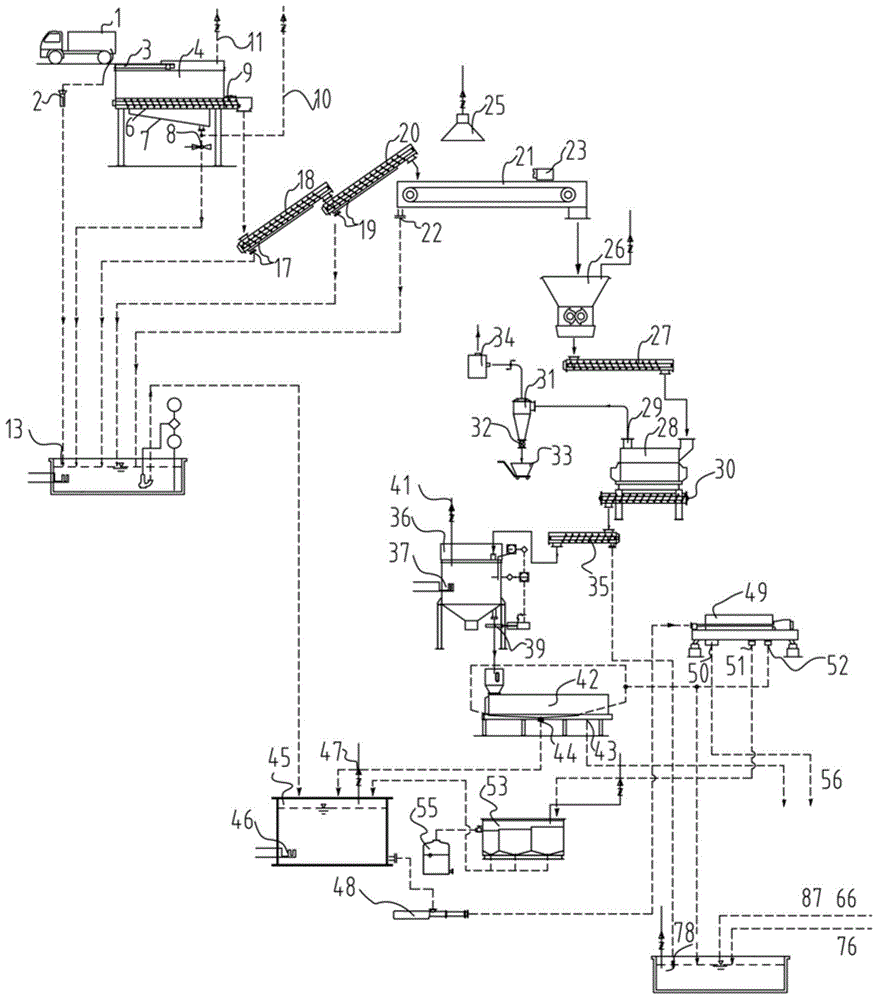

[0028] refer to figure 1 , the workflow of the preprocessing subsystem and the corresponding equipment for realizing the workflow will be described in detail below.

[0029]The food waste truck with a sewage tank (1) transports the food waste to the starting point of the pretreatment subsystem of the food waste treatment system, in which the food waste is roughly divided into soli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com