Chemical gas regulating agent and preparation method thereof

A gas-conditioning agent and chemical technology, applied in the field of chemical gas-conditioning agent and its preparation, can solve the problems of deoxidizer agglomeration, affecting deoxidation ability, poor fluidity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

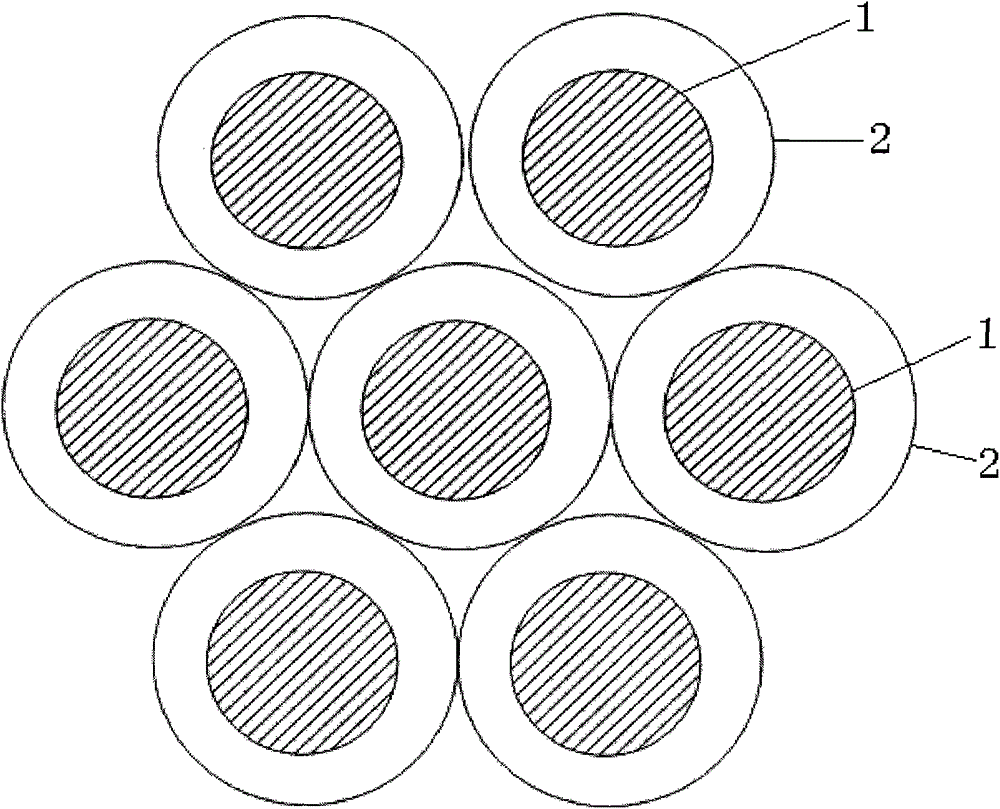

[0031] This embodiment provides a chemical air conditioning agent, which includes an inner core and a shell disposed outside the inner core, the inner core is a deoxidizer, and the outer shell includes a catalyst capable of catalyzing the deoxidizing reaction of the deoxidizer and a binder. In the chemical air conditioning agent, the inner core deoxidizer chemically reacts with oxygen, thereby deoxidizing. The catalyst in the chemical atmosphere control agent can catalyze the deoxidation of the deoxidizer. In order to form the core-shell structure of the chemical atmosphere control agent, the catalyst needs to be placed on the outer layer of the core deoxidizer to form a shell, but there is no stickiness between the catalyst and the deoxidizer. Therefore, it is necessary to bond the catalyst to the outer layer of the core deoxidizer through an adhesive, so that the shell provided outside the core deoxidizer includes a catalyst and a binder. The shell including the catalyst and ...

Embodiment 2

[0037] Such as figure 1 As shown, this embodiment provides a chemical atmosphere control agent, which includes an inner core 1 and a shell 2 disposed outside the inner core 1, and the particle size of the chemical atmosphere control agent is 80 mesh sieve particles.

[0038] The inner core 1 is iron powder as a deoxidizer, and the outer shell 2 includes a catalyst lithium chloride capable of catalyzing the deoxidizing reaction of the deoxidizer, and a binder sodium alginate. The mass of the catalyst lithium chloride accounts for 0.001% of the mass of the chemical air conditioning agent, and the mass of the binder sodium alginate accounts for 0.1% of the mass of the chemical air conditioning agent.

[0039] This embodiment also provides a method for preparing a chemical atmosphere control agent, including the following steps:

[0040] Put the deoxidizer iron powder into the fluidized bed so that the inlet air temperature of the deoxidizer iron powder in the fluidized state is 45℃, th...

Embodiment 3

[0045] The present embodiment provides a chemical air conditioning agent, which includes an inner core and a shell arranged outside the inner core, and the particle size of the chemical air conditioning agent is particles passing a 200 mesh sieve.

[0046] The inner core is a mixture of zinc powder as a deoxidizer and copper powder as a deoxidizer (the mass ratio of zinc powder to copper powder is 1:1), and the outer shell includes a catalyst sodium nitrate capable of catalyzing the deoxidizer to undergo deoxidation reaction, and viscous Binder carboxymethyl cellulose and binder hydroxymethyl cellulose (the mass ratio of carboxymethyl cellulose and hydroxymethyl cellulose is 3:4). The mass of the catalyst sodium nitrate accounts for 10% of the mass of the chemical air conditioning agent, and the mass of the binder carboxymethyl cellulose and the binder hydroxymethyl cellulose accounts for 15% of the mass of the chemical air conditioning agent.

[0047] This embodiment also provides...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com