Spindle synchronous motor with wide speed regulation range for lathe

A technology of synchronous motor and wide speed regulation, which is applied in the field of permanent magnet motor and lathe spindle synchronous motor. Speed range, stability improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

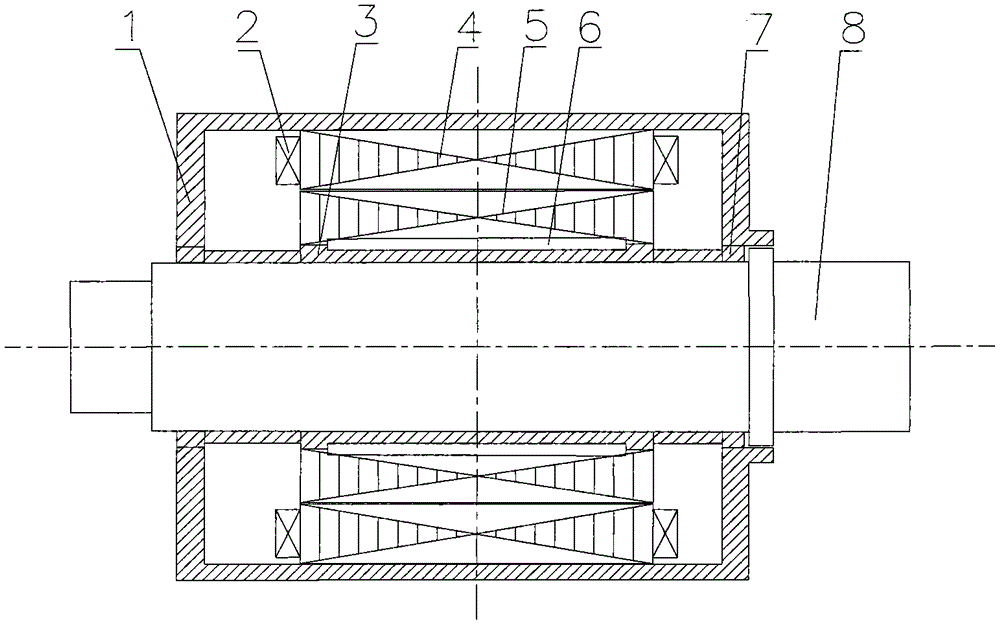

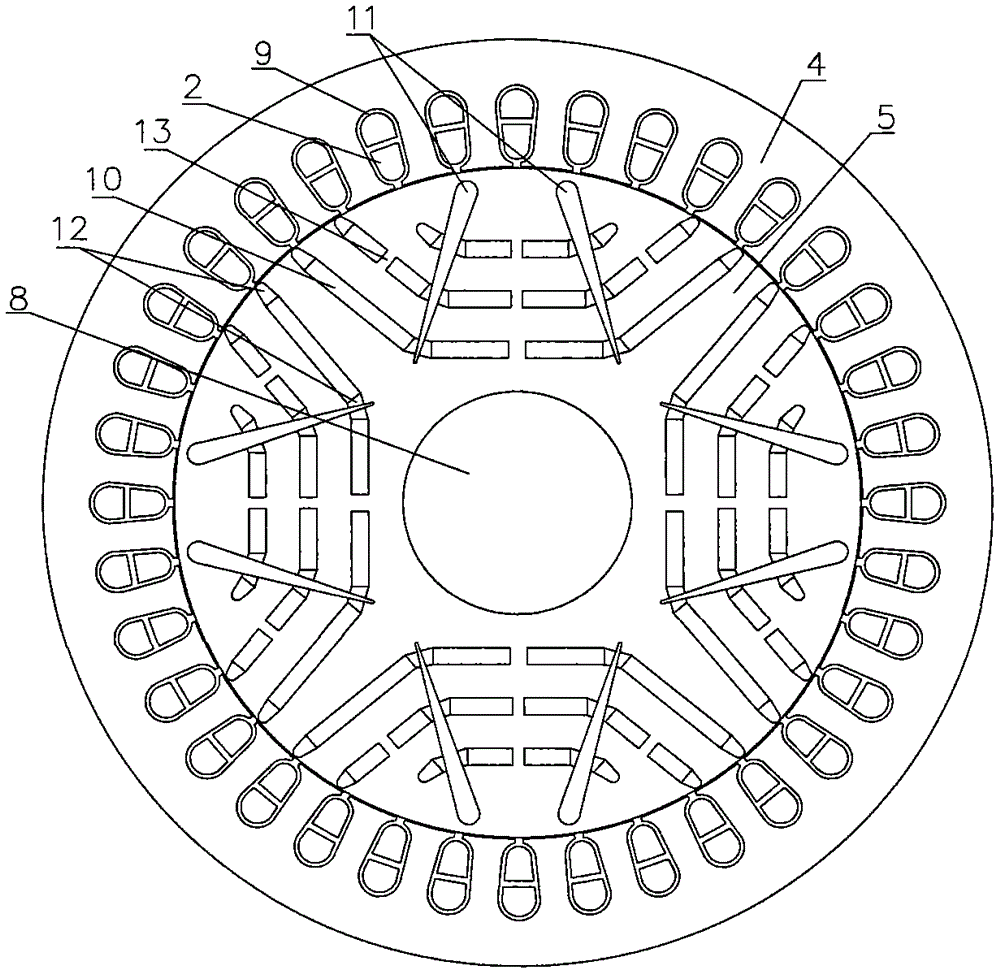

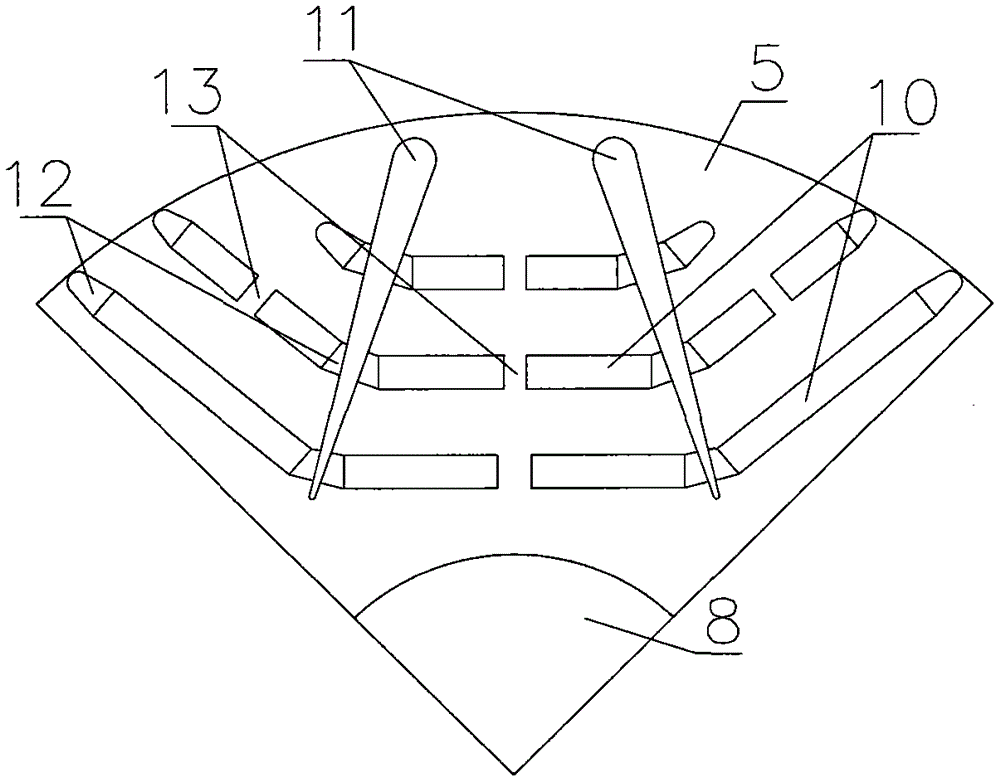

[0017] This patent is a kind of spindle synchronous motor with wide speed regulation range for lathe, such as figure 1 As shown, the rotor core 5 is installed on the inner side of the stator core 4, the stator core 4 and the rotor core 5 are both made of laminated silicon steel sheets, the stator slot 9 located in the stator core 4 is filled with the three-phase winding 2, and the inside of the rotor core 5 Embedded permanent magnet 10 is installed. The rotor structure diagram is as follows figure 2 , image 3 As shown, the rotor core 5 is embedded with three layers of permanent magnets 10 that are radially separated from each other. There are magnetic bridges between the permanent magnets and the circumference of the rotor, and between the permanent magnets and the double-layer magnetic barrier 11 formed by the elongated hollow holes. 12....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com