An OLED device structure and 3D printing technology based multiple-spray-head printing method thereof

A device structure, multi-nozzle technology, applied in the direction of electric solid device, semiconductor device, semiconductor/solid state device manufacturing, etc., can solve the problems of reducing production cost, troublesome and time-consuming filling of layer-by-layer printing materials, etc., to reduce working time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments are described in detail in conjunction with the accompanying drawings.

[0026] The present invention will be further described in detail through specific examples below.

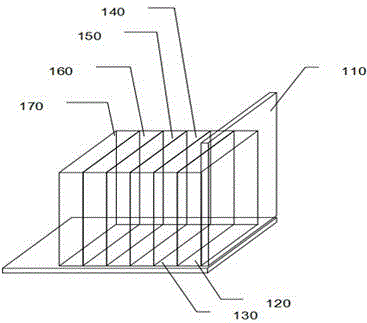

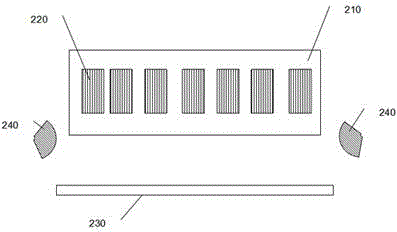

[0027] refer to Figure 1 to Figure 5 , The invention relates to an OLED device structure, comprising a glass substrate arranged on the bottom layer, on which an anode layer, a hole transport layer, an organic light-emitting layer, an electron injection buffer layer, a cathode layer and an encapsulation film layer are sequentially arranged.

[0028] The above-mentioned anode layer is made of ITO powder; the hole transport layer is made of NPB powder, TPD powder or a mixture of two kinds; the organic light-emitting layer is made of Alq 3 powder; the electron injection buffer layer is made of LiF powder; the cathode layer is made of Al powder, Ag powder or a mix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com