A device for recovering associated gas in a cluster well group and its recovery method

A recovery method and associated gas technology, applied in earthwork drilling, wellbore/well components, and production fluids, etc., can solve the problems of not forming an economical utilization scale, wasting precious resources, polluting the environment, etc., and achieve social and economic benefits Significant, reducing the effect of flare venting and protecting the ecological environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

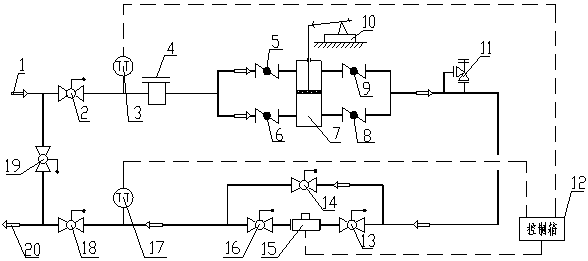

[0020] The associated gas recovery device for the cluster well group provided by the present invention, such as figure 1 As shown, it includes a first ball valve 2, a filter 4, a booster system, and a fifth ball valve 18 connected in sequence from the associated gas input end 1 to the associated gas output end 20, wherein the booster system is composed of an increaser pressure device 7 and four check valves, the filter 4 is connected to the upper and lower air inlets on one side of the booster device 7 through the first check valve 5 and the second check valve 6 respectively, and the other side of the booster device 7 The upper air outlet and the lower air outlet are respectively connected to the fifth ball valve 18 through the third check valve 8 and the fourth check valve 9, and the top end of the piston rod of the supercharging device 7 is hinged with the beam of the pumping unit 10.

[0021] After the associated gas recovery device is connected according to the above-menti...

Embodiment 2

[0034] A flow meter 15 is arranged between the pressurization system of this embodiment and the fifth ball valve 18, the pressurization system is connected to the flow meter 15 through the second ball valve 13 through a pipeline, and the flow meter 15 is output with the associated gas through the fourth ball valve 16 The fifth ball valve 18 at end 20 is connected through pipelines, and the pressurized system is also directly connected to the fifth ball valve 18 through the third ball valve 14 .

[0035] Open the second ball valve 13 and the fourth ball valve 16, close the third ball valve 14, the pressurized associated gas passes through the second ball valve 13, is measured by the flow meter 15, and then is output through the fourth ball valve 16 and the fifth ball valve 18 respectively. , and finally mixed with crude oil to the downstream; when metering is not required, the second ball valve 13 and the fourth ball valve 16 are closed, the third ball valve 14 is opened, and th...

Embodiment 3

[0039] The associated gas supercharging device 7 hinges the cylinder part of the supercharging device 7 with the support of the pumping unit 10 by measuring the upper and lower dead center positions of the oil beam of the pumping unit 10, and the upper part of the piston rod of the supercharging device 7 is connected with the oil pumping unit. The beam of the pumping unit 10 is hinged; the pumping unit 10 drives the piston rod of the device to go up or down through the up and down strokes to suck and compress the gas.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com