Construction method for pedestal piles

A construction method and bottom-expanding pile technology, which is applied in sheet pile walls, foundation structure engineering, construction, etc., can solve problems such as large vibration and noise, difficult sinking of pile bottoms, and adverse effects, and achieve low excitation force and noise, Guarantee the effect of pile quality and high bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

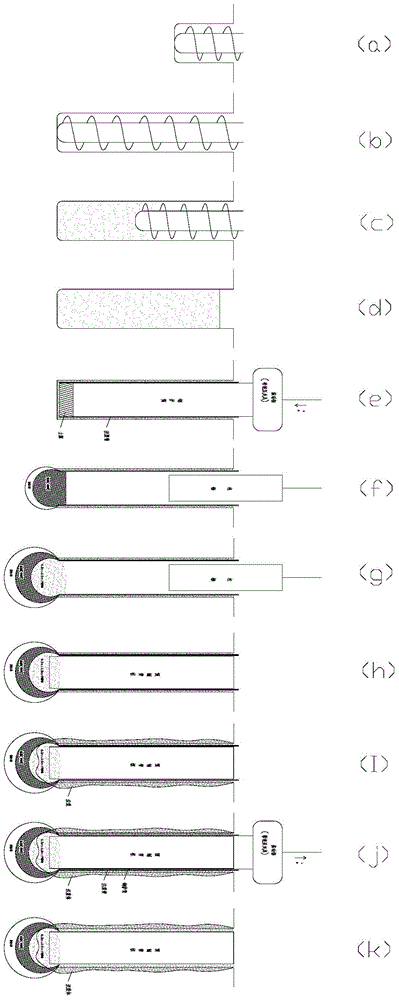

[0039] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0040] Such as figure 1 As shown, a kind of construction method of bottom expansion pile provided by the present embodiment comprises the following steps:

[0041] ① On the predetermined pile position, use the drilling rig to drill to the set depth and press fill the filling body into the drill hole; use the long helical drilling and filling process or the two-way spiral extrusion process to complete the filling body. In the helical drilling pressure irrigation process, after the drilling is completed, the drill pipe is lifted up while the filler is pumped into the drilled hole;

[0042] The filling body is composed of one or more of mud, cement soil, cement sand soil and cement fly ash sand soil, and the filling body is liquid, and the input amount of the filling body is 40%-60% of the drilling volume;

[0043] Insert the steel casing into the above-mentioned dri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com