Making method of spherical layered antimony sulfide film

A thin film preparation, antimony sulfide technology, applied in chemical instruments and methods, coatings, inorganic chemistry, etc., can solve the problems of organic solvent carbon pollution, expensive equipment, high assembly cost, and achieve simple preparation process, low price, and overcome the The effect of high temperature and high pressure environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] A method for preparing a spherical layered antimony sulfide thin film, comprising the steps of:

[0022] ① Substrate pre-processing

[0023] The cut glass substrates were ultrasonically cleaned in 50ml distilled water, 50ml acetone, and 50ml absolute ethanol for 30 minutes, then soaked in piranha solution for 5-60 minutes, and then dried with nitrogen for later use; the piranha solution was H 2 SO 4 with H 2 o 2 Mix the solution, the volume ratio of the two is 3:1;

[0024] ② Thin film precursor solution preparation

[0025] Analytical pure 0.003mol Na 2 S 2 o 3 ·5H 2 O was dissolved in deionized water, and analytically pure 0.002mol SbCl 3 2H 2 O was dissolved in concentrated HCl, then the two solutions were mixed and the volume was adjusted to 100ml, the solution was stirred on a magnetic stirrer for 5 minutes, ammonia water was added dropwise to adjust the pH value of the precursor solution between 2-5; the two solutions were mixed and volume was reached to...

Embodiment 1

[0030] The cut glass substrates were ultrasonically cleaned in 50ml distilled water, 50ml acetone, and 50ml absolute ethanol for 30 minutes, then soaked in piranha solution for 10 minutes, and dried with nitrogen for later use; analytically pure 0.003mol Na 2 S 2 o 3 ·5H 2 O was dissolved in deionized water, and analytically pure 0.002mol SbCl 3 2H 2 Dissolve O in concentrated HCl, then mix the two solutions to 100ml, stir the solution on a magnetic stirrer for 5 minutes, add ammonia water dropwise to adjust the pH value of the precursor solution to 2.0; place the treated substrate in the prepared precursor solution Thin film deposition was carried out at 8 h at a deposition temperature of 30°C; the deposited thin film was heat-treated at 200°C for 2 h to obtain a spherical layered antimony sulfide thin film.

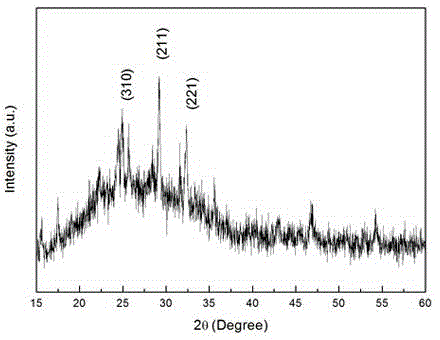

[0031] The XRD test of the successfully prepared antimony sulfide thin film see figure 1 , the diffraction peaks in the figure correspond to the characteristic pea...

Embodiment 2

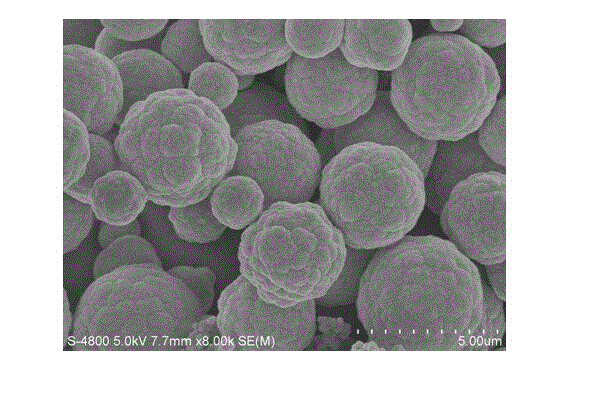

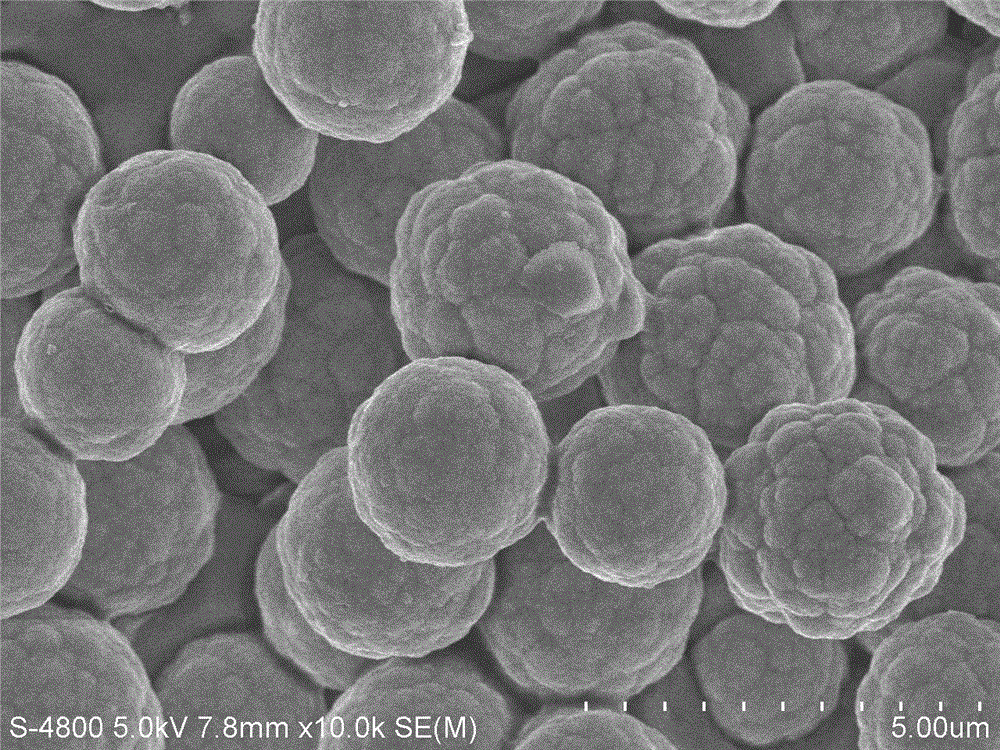

[0033] The cut glass substrates were placed in 50ml of distilled water, 50ml of acetone, and 50ml of absolute ethanol for 30min ultrasonic cleaning, then soaked in piranha solution for 30min, and dried with nitrogen for later use; analytically pure 0.003mol Na 2 S 2 o 3 ·5H 2 O was dissolved in deionized water, and analytically pure 0.002mol SbCl 3 2H 2 Dissolve O in concentrated HCl, then mix the two solutions to 100ml, stir the solution on a magnetic stirrer for 5 minutes, add ammonia water dropwise to adjust the pH value of the precursor solution to 5.0; place the treated substrate in the prepared precursor solution Thin film deposition was carried out at 12 h at a deposition temperature of 50°C; the deposited thin film was heat-treated at 400°C for 2 h to obtain a spherical layered antimony sulfide thin film. Spherical lamellar morphology see image 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com