Non-thermal preparation method of fruit and vegetable juice and beverage thereof

A fruit and vegetable juice and vegetable technology, applied in the field of non-thermal preparation of fruit and vegetable juice and its beverages, can solve the problems of restricting the commercial application of HHP, poor sterilization effect, equipment loss, etc., to ensure product quality, functional nutrition, and small nutritional loss , Guarantee the effect of safety and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

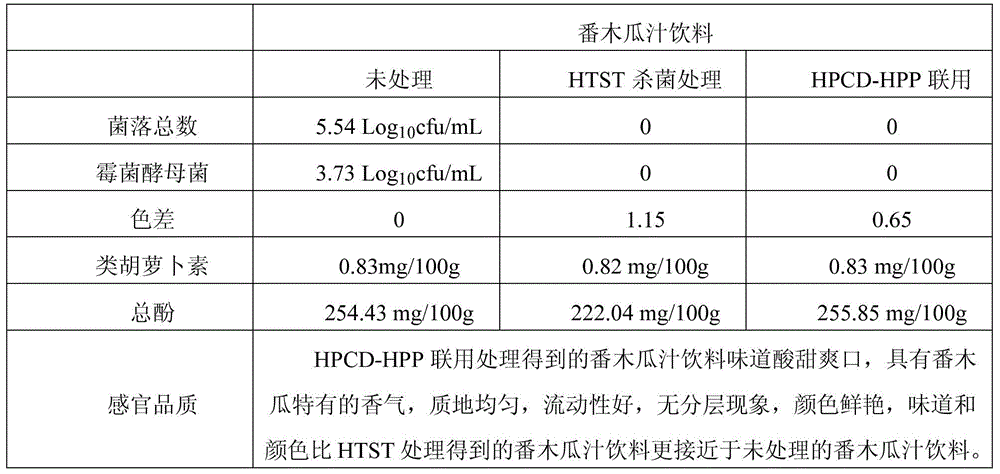

[0044] Example 1. Processing of HPCD-HHP papaya juice beverage

[0045] (1) Raw material pretreatment: select mature, no rot, no diseases, insect pests and mechanical damage of papaya, clean it, peel the clean papaya, remove the seeds, and cut into slices about 4mm;

[0046] (2) Blanching: slice the papaya, blanch it with steam for 5 minutes, and cool it quickly with drinking water;

[0047] (3) Beating: Mix the blanched papaya slices with drinking water at a mass ratio of 1:4, and use a beater to beat to obtain papaya juice;

[0048] (4) Blending: Add food grade white sugar and food grade citric acid to the papaya pulp for flavoring. The addition amount of white sugar and citric acid is based on the quality of the papaya pulp juice, and the amount of white sugar added is the papaya juice. 8% of the quality of papaya juice, and the amount of citric acid added is 0.2% of the quality of papaya juice;

[0049] (5) Gum milling, homogenization, and degassing: use a colloid mill and a homoge...

Embodiment 2

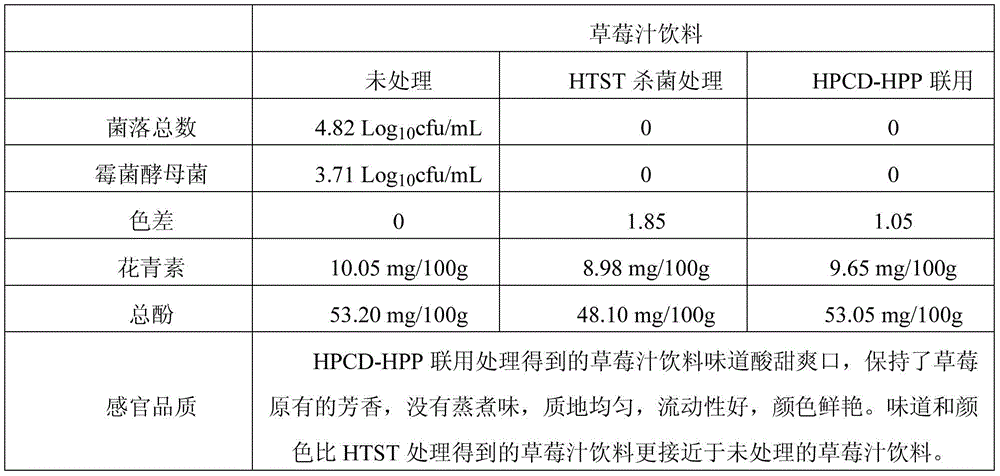

[0058] Example 2. Processing of HPCD-HHP strawberry juice beverage

[0059] (1) Raw material pretreatment: select fresh, complete, and non-rotted strawberries, wash them, remove the leaves, and cut into slices of about 4 mm;

[0060] (2) Blanching: slice the strawberries, blanch them with steam for 2 minutes, and cool them quickly with drinking water;

[0061] (3) Beating: Mix the blanched strawberry slices with drinking water in a ratio of 1:1.5, and use a beater to beat to obtain strawberry juice;

[0062] (4) Blending: Add food-grade white sugar and food-grade citric acid to the strawberry syrup for flavoring. The amount of white sugar and citric acid added is based on the quality of the strawberry syrup, and the amount of white sugar added is the strawberry syrup 10% of the mass, the addition of citric acid is 0.3% of the mass of papaya juice;

[0063] (5) Glue milling, homogenization, and degassing: use a colloid mill and a homogenizer to glue and homogenize the prepared strawberr...

Embodiment 3

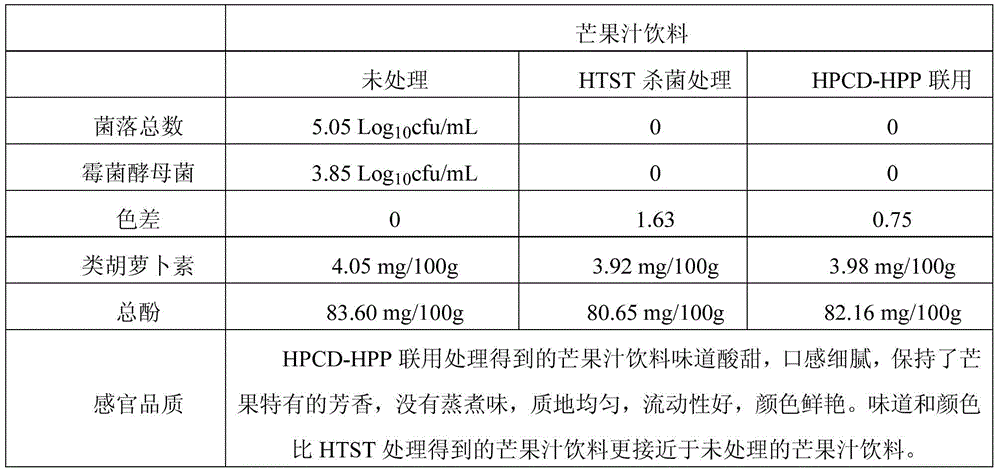

[0073] Example 3 Processing of HPCD-HHP mango juice beverage

[0074] (1) Raw material pretreatment: select fresh, complete, and non-rotted mangoes, clean them, and cut them into slices of about 4 mm;

[0075] (2) Blanching: slice the mango, blanch it with steam for 3 minutes, and quickly cool it with drinking water;

[0076] (3) Beating: Mix the blanched mango slices with drinking water in a ratio of 1:3, and use a beater to beat to obtain mango juice;

[0077] (4) Blending: Add food-grade white sugar and food-grade citric acid to the mango syrup for flavoring. The amount of white sugar and citric acid added is based on the quality of the mango syrup, and the amount of white sugar added is the mango syrup. 9% of the mass, and the amount of citric acid added is 0.2% of the mass of mango juice;

[0078] (5) Glue milling, homogenization, and degassing: use a colloid mill and a homogenizer to glue and homogenize the prepared mango slurry in sequence, the number of glue grinding is 3 times...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com