Manufacture method of multi-layer aluminum base sandwich printed circuit board

A manufacturing method and technology of printed boards, applied in the direction of printed circuit manufacturing, printed circuit, processing steps sequence, etc., can solve the problems of resin voids in holes, insufficient glue filling, easy corrosion of aluminum base, etc., and achieve lamination bonding force Good, easy to tear glue, good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The specific embodiment of the present invention is further described below in conjunction with accompanying drawing:

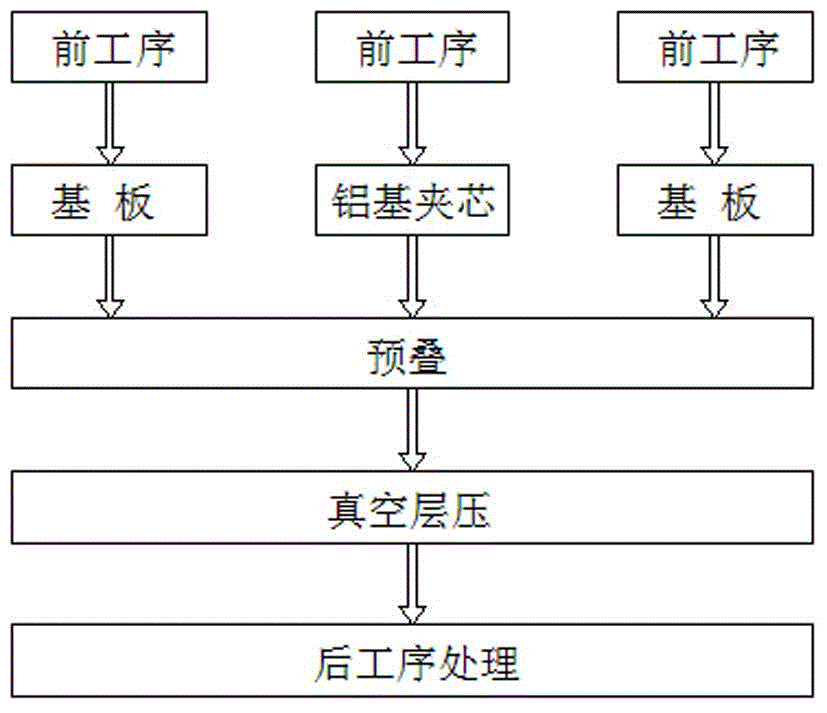

[0039] like figure 1As shown in the process flow chart of the manufacturing method of the multilayer aluminum-based sandwich printed board of the present invention, aluminum material is selected as the aluminum-based sandwich, and copper-clad foil is used as the upper and lower substrates, and the present invention is implemented according to the following steps:

[0040] First, prepare the upper and lower substrates, choose copper clad foil as the upper and lower substrates, and prepare the upper and lower substrates as conventional printed board substrates, mainly including substrate cutting, drilling positioning holes, drilling blind buried holes, copper plating, The steps of inner layer circuit making, blind hole electroplating, inner layer etching, inner layer melting, etc.

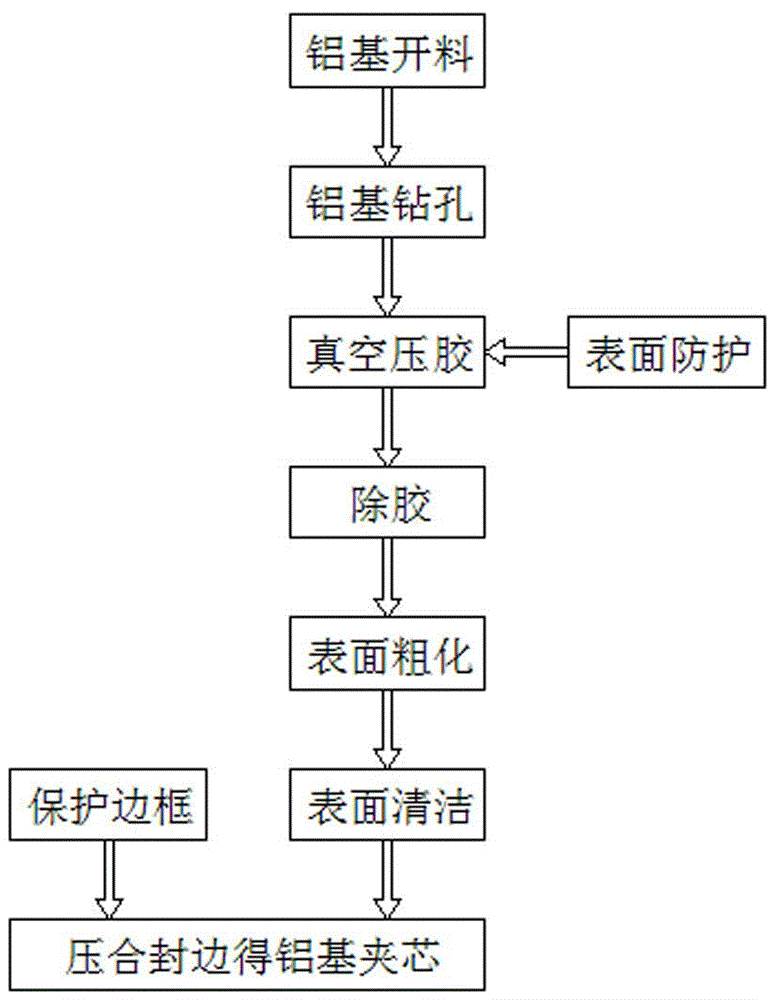

[0041] Secondly, the aluminum-based sandwich core is prepared, combined...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com