Aluminum plastic membrane of polymer lithium-ion power cell and shell punching method of aluminum plastic membrane

A power battery and aluminum-plastic film technology, which is applied in the field of lithium-ion batteries, can solve problems affecting the quality of polymer lithium-ion batteries, corrosion of aluminum-plastic films, and outgassing of batteries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

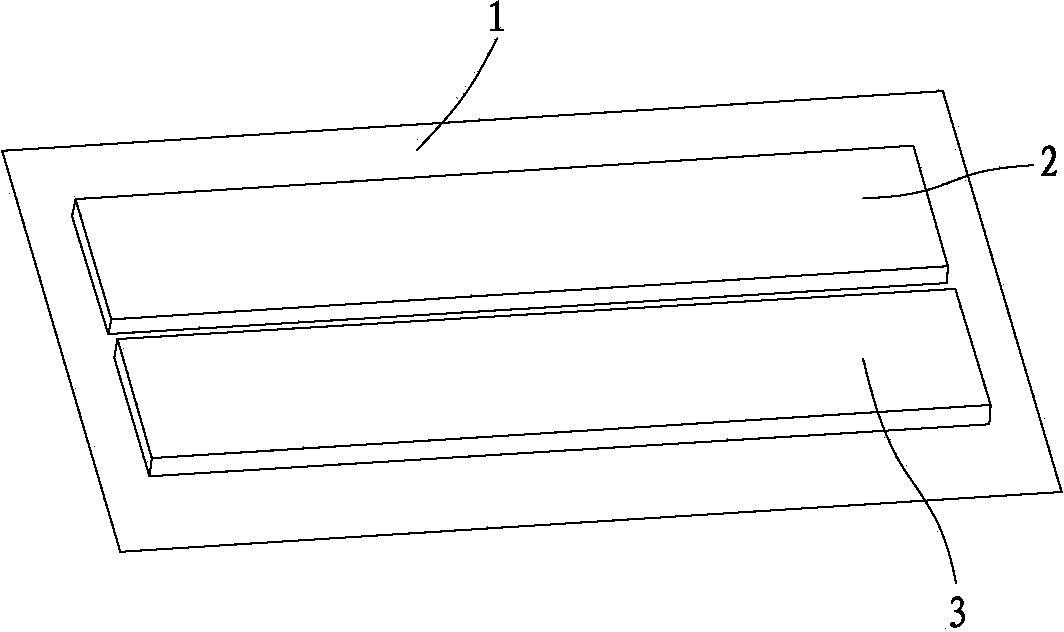

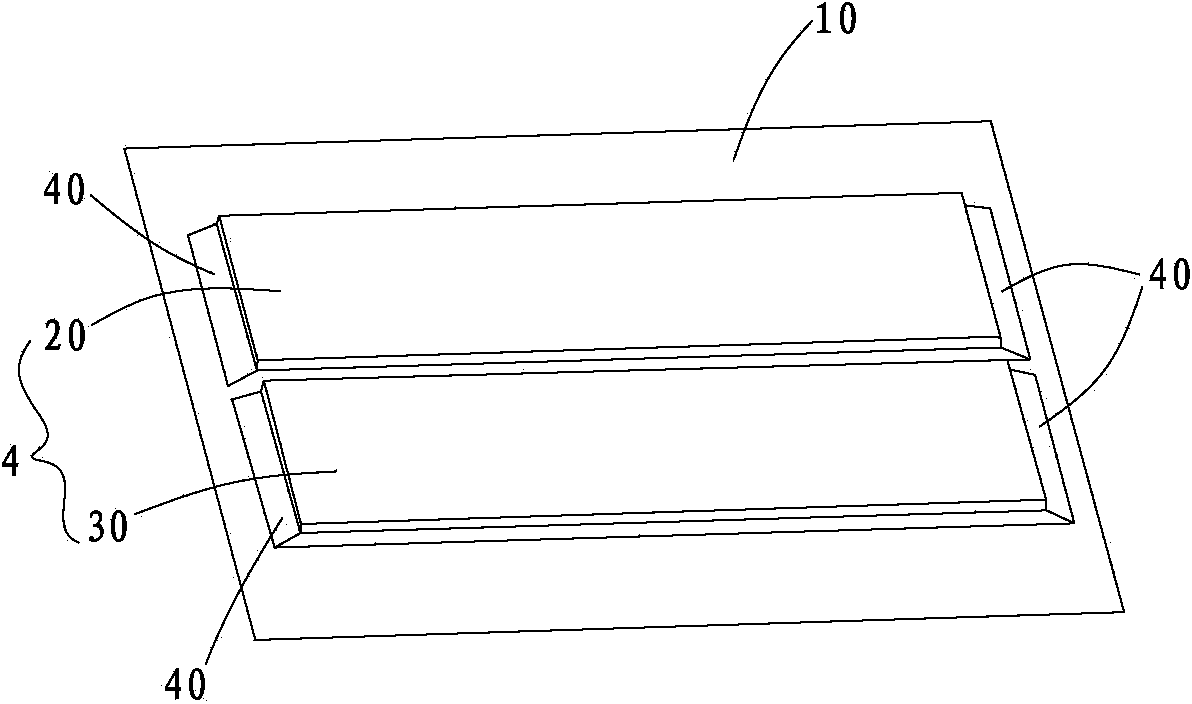

[0022] Specific implementation mode 1, like figure 2 As shown, an aluminum-plastic film of a polymer lithium-ion power battery includes an aluminum-plastic film body 10 and a groove 4 arranged on the aluminum-plastic film body 10, and the groove 4 includes a first groove 20 and the first groove 20. 20 are parallel to the second grooves 30 , both ends of the first groove 20 and the second groove 30 are provided with slopes 40 , and the structural dimensions of the slopes 40 at each place are the same. When the slope 40 is set as a linear slope, the slope of the slope 40 is 15-35°, and the length of the slope 40 is 5-10 mm. When the slope and length of the slope 40 are selected in this range, it is convenient for the electric core body to better cooperate with the first groove 20 and the second groove 30 on the aluminum-plastic film body 10, and avoid the aluminum-plastic film from wrinkling. Corrosion, swelling and leakage inside the battery.

[0023] Generally, the depth ...

specific Embodiment approach 2

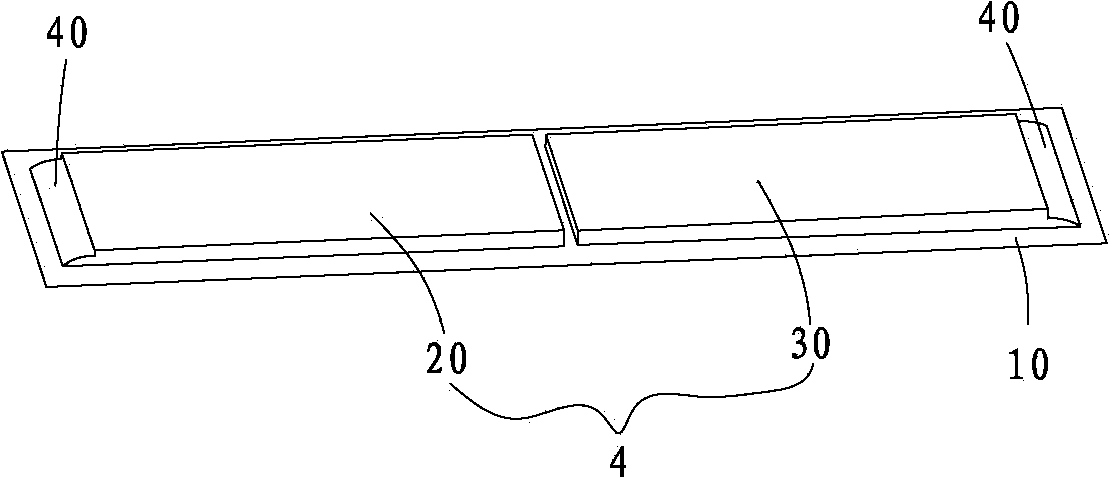

[0024] Specific implementation mode 2, like image 3 As shown, the difference from the specific embodiment 1 is that in this embodiment, one end of the first groove 20 and the second groove 30 is provided with a slope 40, and the slope 40 is configured as an arc-shaped slope. The main reason is that when the cell body is relatively thick, if the linear slope of Embodiment 1 is adopted, it may cause the slope 40 of Embodiment 1 to collapse while the sides of the slope still bulge. A sharp corner is formed at the junction of the surface and the top edge, which eventually leads to easy damage to the sharp corner after packaging. When this happens, it is necessary to make the slope 40 into a certain radian, so that the handover position between the slope 40 and the top sealing edge after packaging is relatively gentle without sharp corners, thereby avoiding the risk of damage to the aluminum-plastic film.

[0025] Preferably, when the slope 40 is set as an arc-shaped slope, the...

specific Embodiment approach 3

[0027] Specific embodiment 3, like figure 2 and 3 As shown, an aluminum-plastic film shell punching method for a polymer lithium-ion power battery in Embodiment 1 or Embodiment 2 is to punch out two symmetrically on both sides of the center line of the aluminum-plastic film body 10 for encapsulating the polymer. The groove 4 of the lithium-ion battery core, and the slope 40 at the connection between the groove 4 and the aluminum-plastic film body 10 .

[0028] Preferably, the aluminum-plastic film body 10 is arranged in a square structure or a strip structure. When the aluminum-plastic film body 10 is arranged in a square structure, the first groove 20 and the second groove 30 are arranged longitudinally, and both ends of the first groove 20 and the second groove 30 are provided with slopes 40, such a structure It is suitable for the case where the tabs are distributed on the exposed parts at both ends of the battery core body. When the aluminum-plastic film body 10 is a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com