Solar cell resisting potential-induced degradation and preparation method thereof

A potential-induced attenuation, solar cell technology, applied in the field of solar cells, can solve the problems of poor battery anti-potential-induced attenuation performance, unsatisfactory battery anti-potential-induced attenuation performance, affecting power output of power stations, etc., to improve battery conversion efficiency, The effect of improving the anti-potential induced decay performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

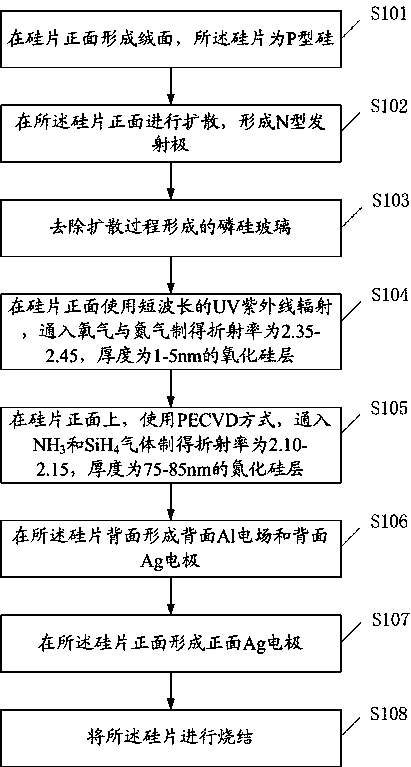

[0049] Correspondingly, see figure 2 , the invention provides a method for preparing a solar cell resistant to potential-induced decay, comprising:

[0050] S101, forming a textured surface on the front surface of the silicon wafer, where the silicon wafer is P-type silicon.

[0051] The textured surface of the silicon chip adopts HF and / or HNO 3 solution to form an ideal suede structure and reduce reflectivity.

[0052] S102, performing diffusion on the front surface of the silicon wafer to form an N-type emitter.

[0053] The N-type emitter can be formed by methods such as thermal diffusion or ion implantation, wherein the diffusion of the silicon wafer is preferably made of phosphorus oxychloride.

[0054] S103, removing the phosphosilicate glass formed in the diffusion process.

[0055] Removing the phosphosilicate glass is beneficial to ensure the photoelectric conversion efficiency of the battery.

[0056] S104, using short-wavelength UV ultraviolet radiation on th...

Embodiment 1

[0067] Forming a suede surface on the front side of the silicon wafer, the silicon wafer is P-type silicon;

[0068] Diffusion is performed on the front side of the silicon wafer to form an N-type emitter;

[0069] Removal of phosphosilicate glass formed by the diffusion process;

[0070] Use short-wavelength UV ultraviolet radiation on the front of the silicon wafer, and pass oxygen and nitrogen to prepare a silicon oxide layer with a refractive index of 2.35 and a thickness of 1nm. The reaction temperature is 50°C, the oxygen flow rate is 15L / min, and the nitrogen flow rate is 10L / min, deposition time 8s;

[0071] On the front side of the silicon wafer, using the PECVD method, first pass the reaction gas NH 3 3.5 slm and SiH 4 900 sccm, the reaction time is 200 s to form the first layer of silicon nitride film; then, change the NH 3 and SiH 4 flow, the NH 3 Flow rate is set to 4.5 slm, SiH 4 The flow rate is set to 500 sccm, the reaction time is 390s, and the second...

Embodiment 2

[0076] Forming a suede surface on the front side of the silicon wafer, the silicon wafer is P-type silicon;

[0077] Diffusion is performed on the front side of the silicon wafer to form an N-type emitter;

[0078] Removal of phosphosilicate glass formed by the diffusion process;

[0079] Use short-wavelength UV ultraviolet radiation on the front of the silicon wafer, and pass oxygen and nitrogen to prepare a silicon oxide layer with a refractive index of 2.37 and a thickness of 2nm. The reaction temperature is 52°C, the oxygen flow rate is 17L / min, and the nitrogen flow rate is 12L / min, deposition time 9s;

[0080] On the front side of the silicon wafer, using the PECVD method, first pass the reaction gas NH 3 3.7 slm and SiH 4 950 sccm, reaction time 205 s to form the first layer of silicon nitride film; then, change the NH 3 and SiH 4 flow, the NH 3 Flow rate is set to 4.8 slm, SiH 4The flow rate is set to 600 sccm, the reaction time is 400s, and the second layer o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com