Crosswind utilized type cooling tower

A cooling tower and cross-wind technology, applied in the direction of water shower coolers, direct contact heat exchangers, heat exchanger types, etc., can solve the problems of cold air backflow, reduced outlet section, uncontrollable direction and wind speed, etc. , to achieve the effect of improving the suction effect and strengthening the suction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

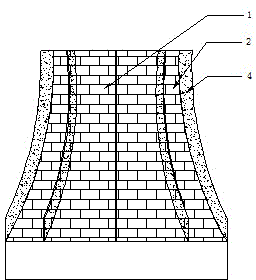

[0018] figure 1 Structural schematic (front view) of a cooling tower utilizing a crosswind with deflectors. The side wind utilizes a cooling tower, including a conventional cooling tower (1) and a diversion baffle (4), and is characterized in that a plurality of diversion baffles are installed at different angles in the circumferential direction on the side wall (2) of the cooling tower. The diversion partitions are installed vertically along the direction of the cooling tower bus. The guide baffles are evenly installed on the side walls around the cooling tower, or concentratedly installed on the side of the cooling tower that suffers from strong winds for a long time. The cross section of the diversion baffle can be designed in the shape of rectangle, trapezoid or triangle.

[0019] A kind of concrete implementation of the present invention is as follows: firstly according to cooling tower characteristic parameter, local environment side wind speed, temperature, sunshine ...

Embodiment 2

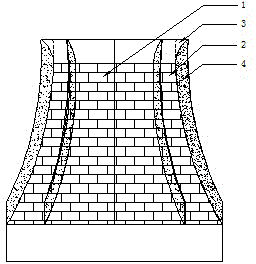

[0023] figure 2 Structural schematic (front view) of a cooling tower for a crosswind utilization with deflectors and deflector crowns. The side wind uses a cooling tower, including a conventional cooling tower (1), a diversion crown (3) and a diversion partition (4), which is characterized in that multiple Diversion partition. The diversion partitions are installed vertically along the direction of the cooling tower bus. The guide baffles are evenly installed on the side walls around the cooling tower, or concentratedly installed on the side of the cooling tower that suffers from strong winds for a long time. The cross section of the diversion baffle can be designed in the shape of rectangle, trapezoid or triangle. A diversion crown is installed on the periphery of the outlet of the cooling tower, its lower edge is installed close to the side wall of the cooling tower, and its outer surface replaces the side wall of the cooling tower covered by it to intersect with the div...

Embodiment 3

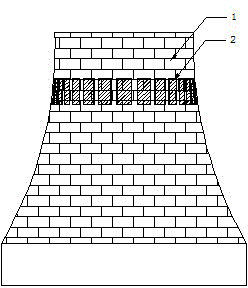

[0028] image 3Structural schematic (front view) of a cooling tower for a crosswind utilization with side windows. The side wind utilizes a cooling tower, including a conventional cooling tower (1) and a side window (5), and is characterized in that: the side window is provided on the cooling side wall. The side window is set at the waist or above the waist, and a backstop damper is installed on the side window.

[0029] A kind of concrete implementation of the present invention is as follows:

[0030] First, select the material of the side window frame, such as plastic, metal, alloy, foam filling material, etc., according to the characteristic parameters of the cooling tower, the local environmental side wind speed, temperature, sunshine and other weather conditions. Then, according to the characteristic parameters of the cooling tower and the wind force, temperature, sunshine and other parameter requirements, optimize the design of the basic data and processing drawings su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com