Method for catalytically converting biomass into lactic acid by using modified beta-molecular sieve

一种β分子筛、催化转化的技术,应用在乳酸领域,能够解决产物与催化剂分离未解决等问题,达到制备过程简易、乳酸产率高、反应原料低廉易得的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Catalyst preparation: mix β molecular sieve with concentrated nitric acid at a mass ratio of 1:110, at a temperature of 100 o Stirring and dealumination at C for 20 h, centrifugation and washing 8 times, 80 o C drying for 2 h, then 150 o C dried for 10 h to obtain dealuminated β molecular sieves, mixed 1 g of dealuminated β molecular sieves with 83.85 mg copper acetate (0.42 mmol Cu), and ground for 15 min at a temperature of 550 o C, Calcined in the air atmosphere for 6 h, the aluminum-free Cu-β molecular sieve catalyst can be obtained.

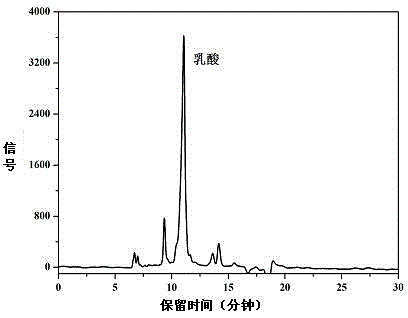

[0025] Catalytic reaction: The reaction was carried out in a stainless steel reactor lined with polytetrafluoroethylene, weighed 225 mg of glucose, 160 mg of aluminum-free Cu-β molecular sieve catalyst, and 10 g of deionized water, and directly placed the reactor in the The reaction was carried out in a rotary oven, the rotation speed of the rotary oven was 20 r / min, and the temperature was 190 o C, the reaction time was 2 h; the p...

Embodiment 2

[0027] Catalyst preparation: mix β molecular sieve with concentrated nitric acid at a mass ratio of 1:110, at a temperature of 100 o Stirring and dealumination at C for 20 h, centrifugation and washing 8 times, 80 o C drying for 2 h, then 150 o C drying for 10 h to obtain dealuminated β molecular sieves, mixed 1 g of dealuminated β molecular sieves with 92.19 mg zinc acetate (0.42 mmol Zn), ground for 20 min, at a temperature of 550 o C, Calcined in air atmosphere for 6 h, the aluminum-free Zn-β molecular sieve catalyst can be obtained.

[0028] Catalyzed reaction: The reaction was carried out in a stainless steel reactor lined with polytetrafluoroethylene. Weighed 225 mg of sucrose, 160 mg of aluminum-free Zn-β molecular sieve catalyst, and 10 g of deionized water, and directly placed the reactor in the The reaction was carried out in a rotary oven, the rotation speed of the rotary oven was 20 r / min, and the temperature was 190 o C, the reaction time was 2 h; the product w...

Embodiment 3

[0030] Catalyst preparation: mix β molecular sieve with concentrated nitric acid at a mass ratio of 1:110, at a temperature of 100 o Stirring and dealumination at C for 20 h, centrifugation and washing 8 times, 80 o C drying for 2 h, then 150 o C drying for 10 h to obtain dealuminated β molecular sieve, mixed 1 g of dealuminated β molecular sieve with 92.19 mg of tin acetate (0.42 mmol Sn), ground for 20 min, at a temperature of 550 o C, roasting in air atmosphere for 6 h, the aluminum-free Sn-β molecular sieve catalyst can be obtained.

[0031] Catalytic reaction: The reaction was carried out in a stainless steel reactor lined with polytetrafluoroethylene, weighed 225 mg of sucrose, 160 mg of aluminum-free Sn-β molecular sieve catalyst, and 10 g of deionized water, and directly placed the reactor in the The reaction was carried out in a rotary oven, the rotation speed of the rotary oven was 20 r / min, and the temperature was 190 o C, the reaction time was 2 h; the product w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com