Preparation method of dimethyl ether

A technology of dimethyl ether and plasma, applied in ether preparation, dehydration of hydroxyl-containing compounds to prepare ether, organic chemistry, etc., can solve the problems of low selectivity and low conversion rate of dimethyl ether, and achieve high carbon dioxide utilization rate, The effect of fast reaction rate and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

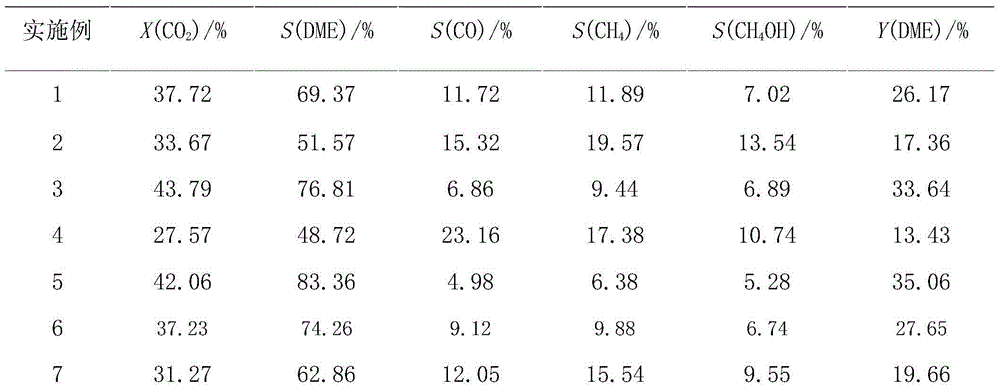

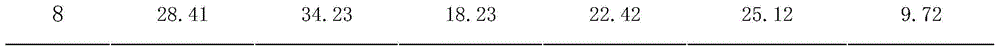

Examples

Embodiment 1

[0024] A kind of preparation method of dimethyl ether

[0025] Spread a layer of 0.5cm thick quartz sand on the plate electrode of the plasma-catalytic reactor, weigh 1g composite catalyst (Cu-Zn-Cr / γ-Al 2 o 3 ) on the quartz sand, and then spread a layer of quartz sand on the composite catalyst, so that the quartz sand-composite catalyst-quartz sand layer reaches 2cm. The flow rate is 30mL·min -1 H 2 , in situ reduction at 300°C for 4h, after the catalyst is reduced and activated, switch to V(H 2 ) / V(CO 2 ) is a reaction raw material gas of 3, the raw material gas flows through a plasma-catalytic reactor with a discharge distance of 8cm, a discharge voltage of 8kV, and a discharge frequency of 8kHz. The reaction pressure is 2.5MPa, the reaction temperature is 280°C, and the reaction space velocity for 2000h -1 The carbon dioxide hydrogenation reaction is carried out under the same conditions, the main product of the reaction is dimethyl ether, and the by-products are ca...

Embodiment 2

[0027] A kind of preparation method of dimethyl ether

[0028] Spread one deck of 0.5cm thick quartz sand on the plate electrode of the plasma-catalytic reactor, take by weighing 1g composite catalyst (Cu-Zn / HZSM-5, the silicon-aluminum ratio of HZSM-5 is 25) and be placed on the quartz sand, Then spread a layer of quartz sand on the composite catalyst, so that the layer of quartz sand-composite catalyst-quartz sand reaches 2cm. The flow rate is 30mL·min -1 H 2 , in situ reduction at 300°C for 4h, after the catalyst is reduced and activated, switch to V(H 2 ) / V(CO 2 ) is the reaction raw material gas of 2, and the raw material gas flows through a plasma-catalytic reactor whose discharge distance is 3cm, discharge voltage is 4kV, and discharge frequency is 8kHz. The reaction pressure is 5MPa, the reaction temperature is 270°C, and the reaction space velocity is 4000h -1 The carbon dioxide hydrogenation reaction is carried out under the same conditions, the main product of ...

Embodiment 3

[0030] A kind of preparation method of dimethyl ether

[0031]Spread a layer of 0.5cm thick quartz sand on the plate electrode of the plasma-catalytic reactor, weigh 1g composite catalyst (Cu-Zn-Al / HZSM-5, the silicon-aluminum ratio of HZSM-5 is 600) and put it on the quartz sand On the sand, lay a layer of quartz sand on the composite catalyst, so that the quartz sand-composite catalyst-quartz sand layer reaches 2cm. The flow rate is 30mL·min -1 H 2 , in situ reduction at 300°C for 4h, after the catalyst is reduced and activated, switch to V(H 2 ) / V(CO 2 ) is the reaction raw material gas of 5, the raw material gas flows through a plasma-catalytic reactor with a discharge distance of 6cm, a discharge voltage of 12kV, and a discharge frequency of 7kHz. The reaction pressure is 3.5MPa, the reaction temperature is 260°C, and the reaction space velocity 3000h -1 The carbon dioxide hydrogenation reaction is carried out under the same conditions, the main product of the reacti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com