A kind of preparation method of silicon calcium potassium magnesium soil conditioner

A soil conditioner, silicon calcium potassium magnesium technology, applied in calcareous fertilizers, fertilizer mixtures, inorganic fertilizers and other directions, can solve the problems of affecting yield and quality, uneven calcination, time-consuming and laborious, etc., to increase storage resistance, improve commodity Value, effect of improving soil performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A. Raw material preparation:

[0039] By weight, including potassium shale 60%, limestone 20%, dolomite 20%;

[0040] B. Grinding:

[0041] Grind the raw materials prepared in step A with a ball mill to 200 mesh;

[0042] C. Calcination:

[0043] Grind the raw materials in step B to 200 mesh, place them in a rotary kiln, and calcine them at 1200° C. to obtain clinker. During calcination, control the calcination time to 45 minutes, and the calcination pressure to 1 atmosphere;

[0044] D. Water quenching:

[0045] The clinker obtained after step C is calcined is immediately conveyed through the conveyor belt for water quenching to obtain a solid product. During water quenching, water spraying at 20°C is used, the water pressure is 1.5 atmospheres, and the conveying speed of the conveyor belt is controlled at 60-80cm / s;

[0046] E. Crushing:

[0047] The solid intermediate product obtained in step D is pulverized to 300 mesh by a pulverizer to obtain a powder;

[...

Embodiment 2

[0053] The difference from Example 1 is that the preparation of raw materials in step A includes 65% of potassium-containing shale, 17.5% of limestone and 17.5% of dolomite by weight ratio. In step C, the calcination temperature is 1160° C., and the calcination time is 50 min.

Embodiment 3

[0055] The difference from Example 1 is that the preparation of raw materials in step A includes, by weight ratio, 70% of potassium-containing shale, 15% of limestone, and 15% of dolomite. In step C, the calcination temperature is 1240° C., and the calcination time is 40 minutes.

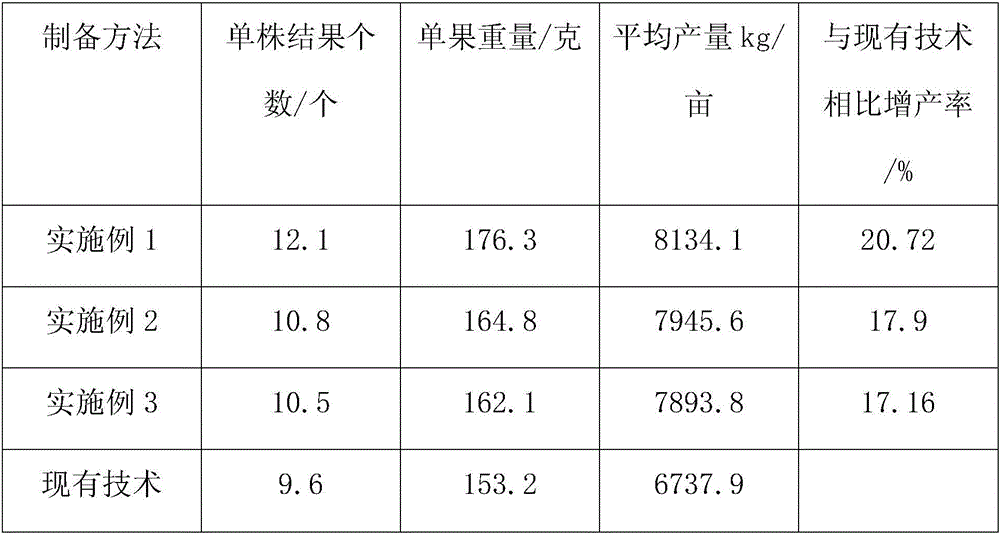

[0056] Product analysis and application effect of the present invention are shown in Table 1-Table 4:

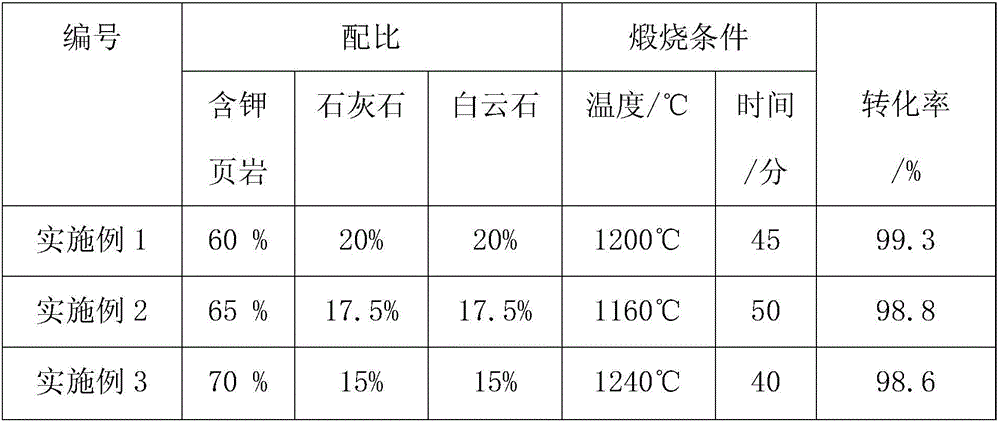

[0057] Table 1 Conversion rate of potassium in potassium shale into available potassium

[0058]

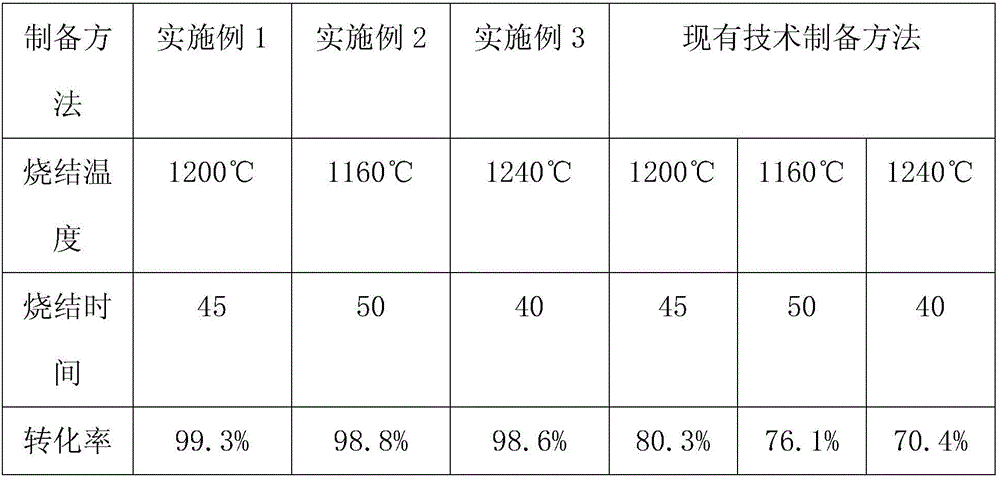

[0059] Table 2 Comparison results of the conversion rate of potassium in potassium-bearing shale into available potassium

[0060]

[0061] It can be clearly shown by Table 1 and Table 2 that the conversion rate of potassium in the potassium-containing shale of the technical solution of the present invention into available potassium is high, which can reach more than 98.6%, and the conversion rate of potassium can be significantly improved, which is obviously higher than current technology.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com