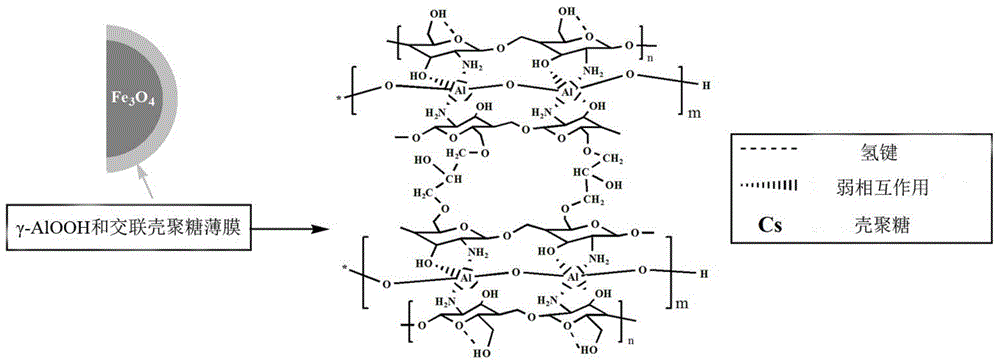

A kind of chitosan-mimetic thin aluminum doped magnetic adsorbent and preparation method thereof

A technology of imitating thin water aluminum and magnetic adsorbent, applied in chemical instruments and methods, adsorbed water/sewage treatment, water pollutants, etc., can solve the problems of long time for precipitation, difficult separation, etc. , large adsorption capacity, strong magnetic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Chitosan-mimetic thin aluminum doped magnetic adsorbent, its preparation process is as follows:

[0026] (1) Weigh 2.0g of ferric chloride (FeCl 3 ·6H 2 O) Evenly dispersed in 80mL ethylene glycol to make a solution. And under stirring condition, add PVP (2.00g) and anhydrous sodium acetate (7.20g) successively, stir to form a homogeneous system. The mixture was transferred to a 100mL reactor with a polytetrafluoroethylene liner and sealed. Finally, the autoclave was placed in an electric blast drying oven and heated to 180°C for constant temperature reaction for 8h. After cooling, the resulting suspension was magnetically separated to obtain a black powdery substance. After washing the powder 3 times with dehydrated ethanol, transfer it to a 50 mL volumetric flask with ethanol as the medium, and dilute to 50 mL with ethanol. A superparamagnetic nano-fluid is obtained.

[0027] (2) Weigh 1.0g of aluminum isopropoxide and dissolve it in 300mL of absolute ethanol, an...

Embodiment 2

[0038]Chitosan-mimetic thin aluminum doped magnetic adsorbent, its preparation process is as follows:

[0039] (1) Weigh 3.0g of ferric chloride (FeCl 3 ·6H 2 O) Evenly dispersed in 80mL ethylene glycol to make a solution. Then add PVP (3.0g) and anhydrous sodium acetate (9.0g) successively under stirring condition, and stir to form a homogeneous system. The mixture was transferred to a 100mL reactor with polytetrafluoroethylene liner and sealed. Finally, the autoclave was placed in an electric blast drying oven and heated to 200°C for constant temperature reaction for 10h. After cooling, the resulting suspension was magnetically separated to obtain a black powdery substance. After washing the powder 3 times with dehydrated ethanol, transfer it to a 50 mL volumetric flask with ethanol as the medium, and dilute to 50 mL with ethanol. A superparamagnetic nano-fluid is obtained.

[0040] (2) Weigh 1.0g of aluminum isopropoxide and dissolve it in 150mL of absolute ethanol, an...

Embodiment 3

[0048] Chitosan-mimetic thin aluminum doped magnetic adsorbent, its preparation process is as follows:

[0049] (1) Weigh 4.0g of ferric chloride (FeCl 3 ·6H 2 O) Evenly dispersed in 80mL ethylene glycol to make a solution. Then add PVP (3.0g) and anhydrous sodium acetate (6.0g) successively under stirring condition, and stir to form a homogeneous system. The mixture was transferred to a 100mL reactor with a polytetrafluoroethylene liner and sealed. Finally, the autoclave was placed in an electric blast drying oven and heated to 160°C for constant temperature reaction for 6h. After cooling, the resulting suspension was magnetically separated to obtain a black powdery substance. After washing the powder 3 times with dehydrated ethanol, transfer it to a 50 mL volumetric flask with ethanol as the medium, and dilute to 50 mL with ethanol. A superparamagnetic nano-fluid is obtained.

[0050] (2) Weigh 0.2g of aluminum isopropoxide and dissolve it in 150mL of absolute ethanol, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com