Perovskite-based thin film solar cell and preparing method thereof

A thin-film solar cell and perovskite technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problem of low hole mobility, achieve simple manufacturing process, easy operation, and expand the application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

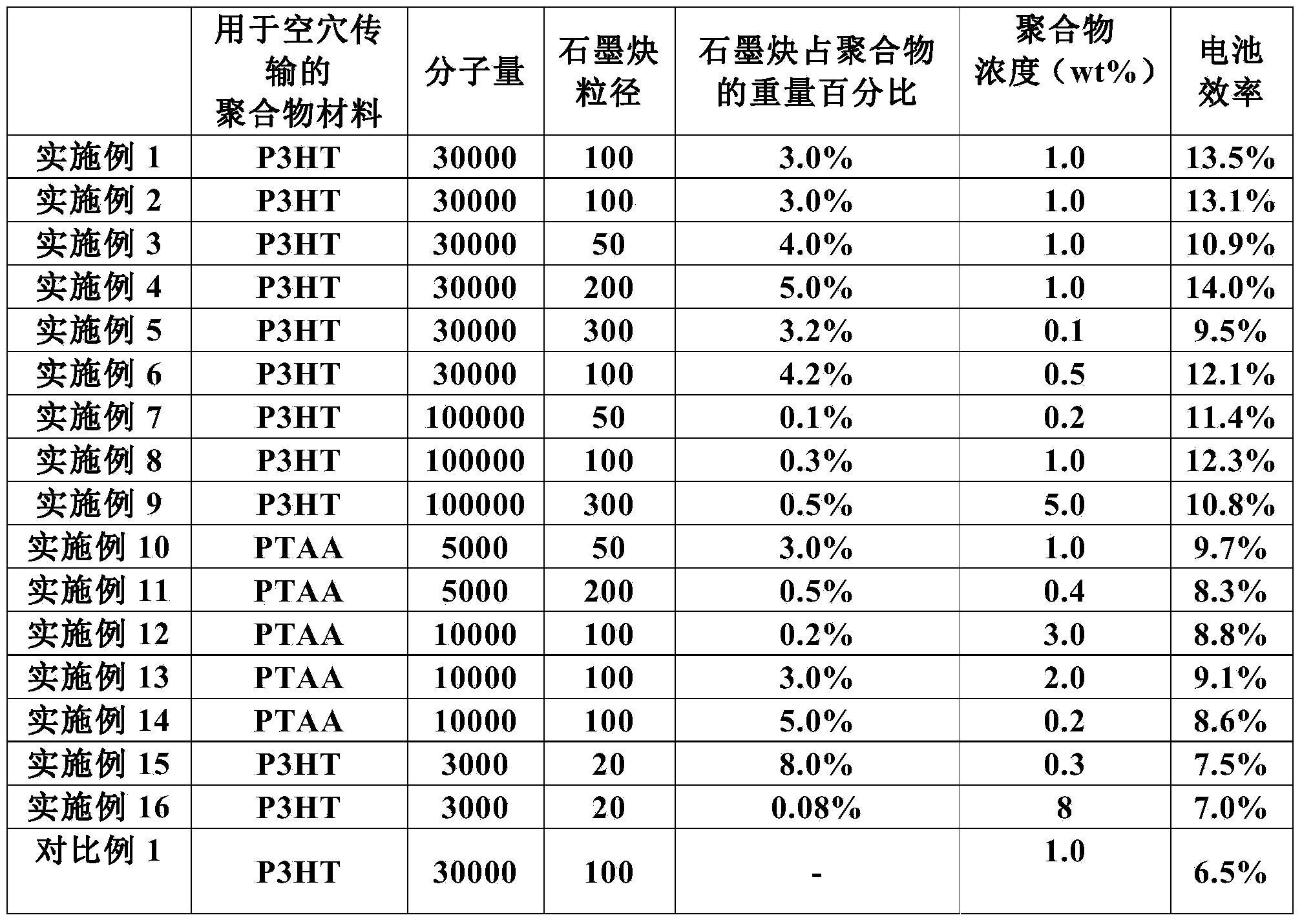

Examples

preparation example Construction

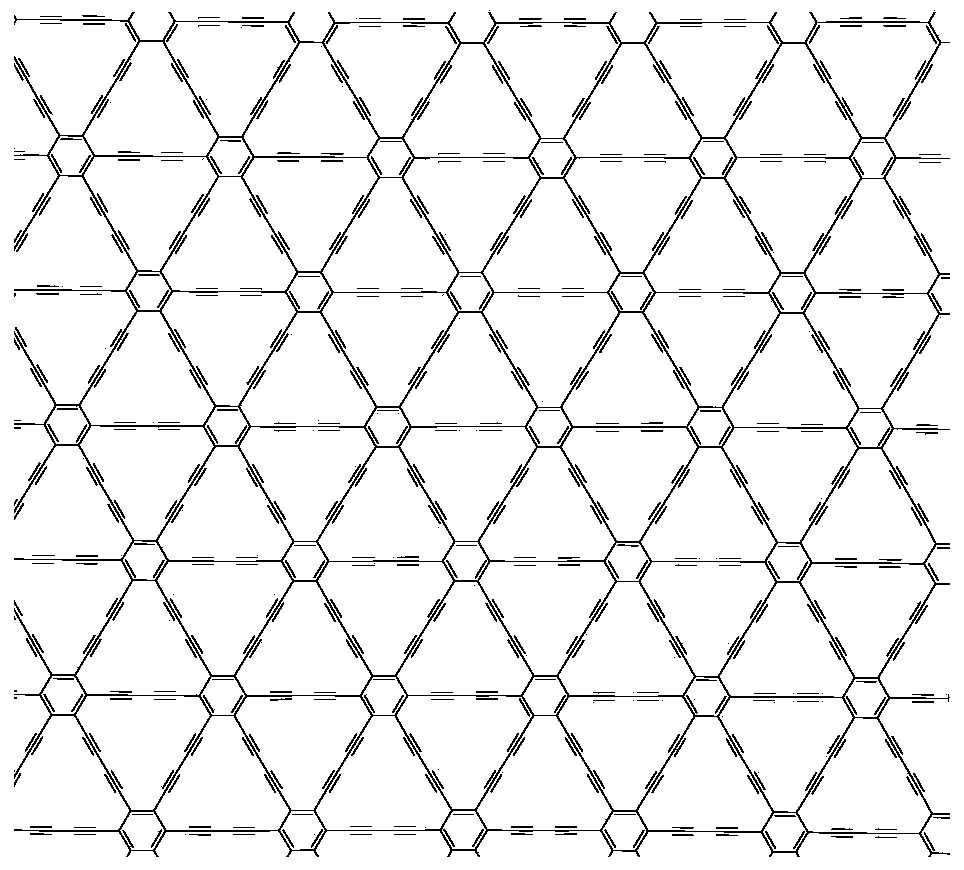

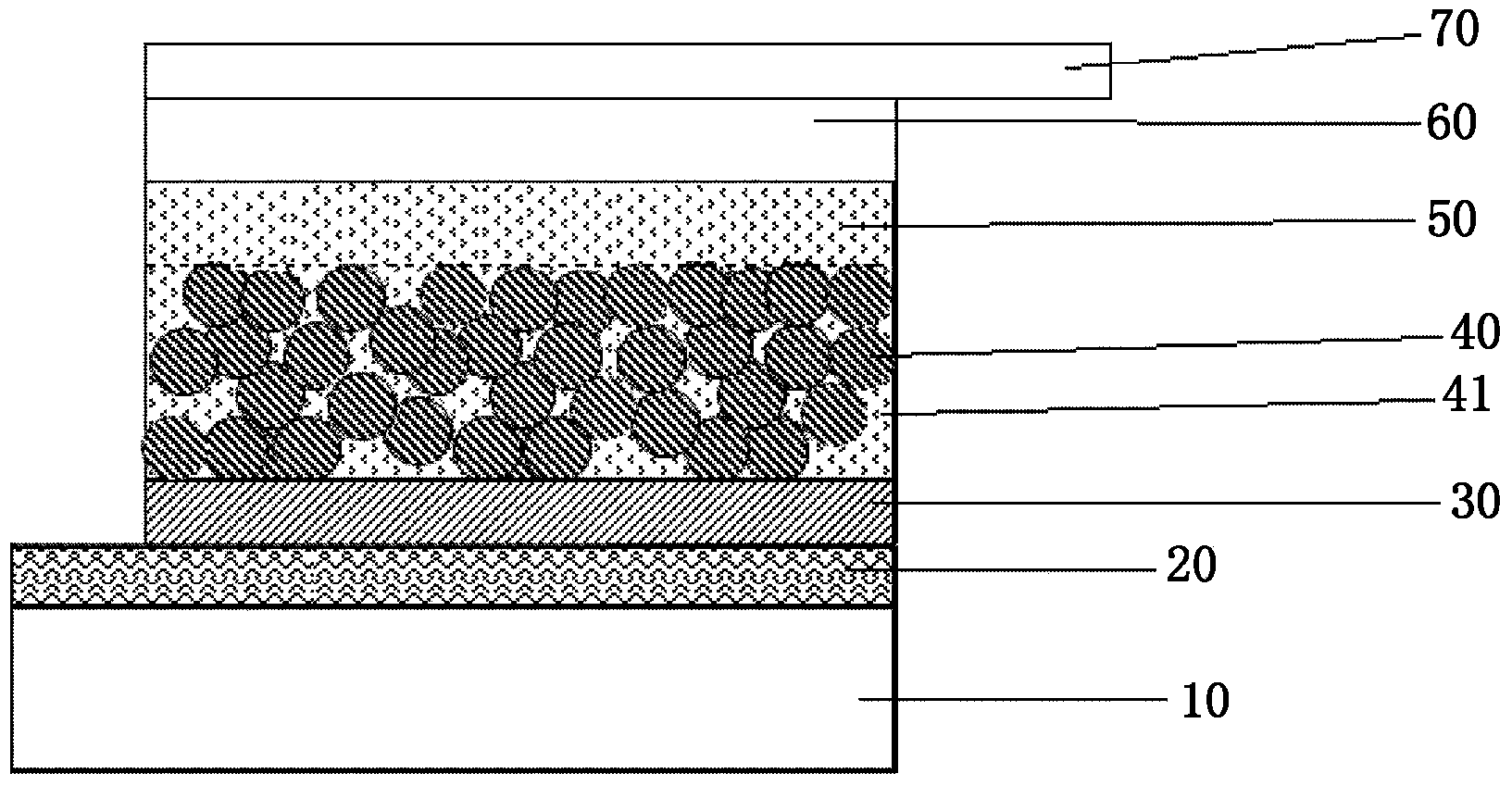

[0043] According to another aspect of the present invention, a method for preparing a perovskite-based thin film solar cell is also provided, including the step of forming a hole transport layer 60 . Wherein, the step of forming the hole transport layer 60 includes: uniformly dispersing the polymer capable of hole transport and graphyne into an organic solvent to form a mixed slurry, and then arranging the mixed slurry on a preformed porous support layer 40 or its capping layer 50; the mixed slurry is dried to form a hole transport layer 60.

[0044] In actual operation, the graphdiyne is generally dispersed in an organic solvent first, and then the polymer material is added after stirring evenly. After the mixed slurry is formed, the mixed slurry is deposited on the porous support layer 40 by coating or screen printing, and then the slurry is dried to form the hole transport layer 60 on the porous support layer 40 . The organic solvent is selected from one or more of benzene...

Embodiment 1

[0049] First, a layer of TiO was screen-printed on the FTO glass 2 Thin film layer, after heating at 450° C. for 30 minutes, a dense layer of semiconductor material with a thickness of 50 nm is obtained. Preferably, the dense layer is formed by printing using the screen printing method disclosed in literature (Chin. Phys. Lett., 2006, 23(9), 2606-2608). TiO coating on dense layer by spin coating method 2 The nanoparticle material is dried at room temperature and then sintered at 500°C to obtain a porous scaffold layer structure with a thickness of 100nm.

[0050] Using a two-step method—spin coating followed by dipping: the PbI 2 Dissolved in N,N-dimethylformamide to prepare a spin-coating solution with a concentration of 32% by mass, spin-coat on the porous support layer at a speed of 3000 rpm, and spin-coat for 30 seconds. Spin-coated PbI 2 The porous scaffold layer film was soaked in CH at a concentration of 10 mg / mL 3 NH 3 In the I solution, an organic metal semicond...

Embodiment 2

[0053] First, a layer of TiO was screen-printed on the FTO glass 2 Thin film layer, after heating at 450° C. for 30 minutes, a dense layer of semiconductor material with a thickness of 50 nm is obtained. Preferably, the dense layer is formed by printing using the screen printing method disclosed in literature (Chin. Phys. Lett., 2006, 23(9), 2606-2608). TiO coating on dense layer by spin coating method 2 The nanoparticle material is dried at room temperature and then sintered at 500°C to obtain a porous scaffold layer structure with a thickness of 100nm.

[0054] The organometallic semiconductor light-absorbing material with a perovskite structure is deposited on the porous scaffold layer by a one-step method. The process includes: equimolar amounts of PbI 3 with organic ammonium iodide CH 3 NH 3 I is co-dissolved in N,N-dimethylformamide, prepared as a spin coating solution with a concentration of 40wt%, and the organometallic semiconductor light-absorbing material is fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com