Steel containment energy control system

A steel containment, energy control technology, applied in nuclear power generation, climate sustainability, emergency protection devices, etc., can solve problems such as increasing construction costs, enhance safety, reduce the possibility of system failure, reduce The effect of construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

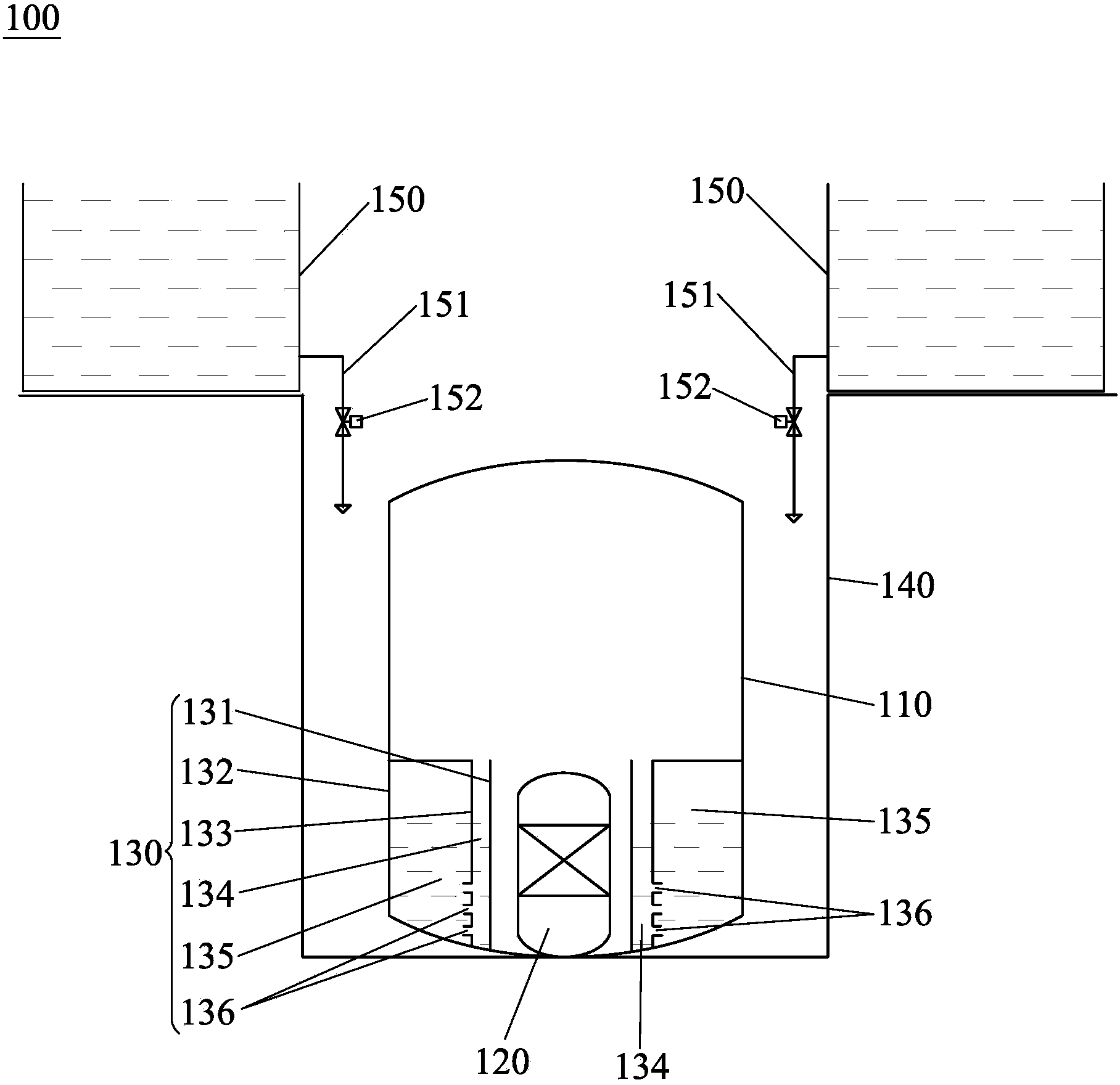

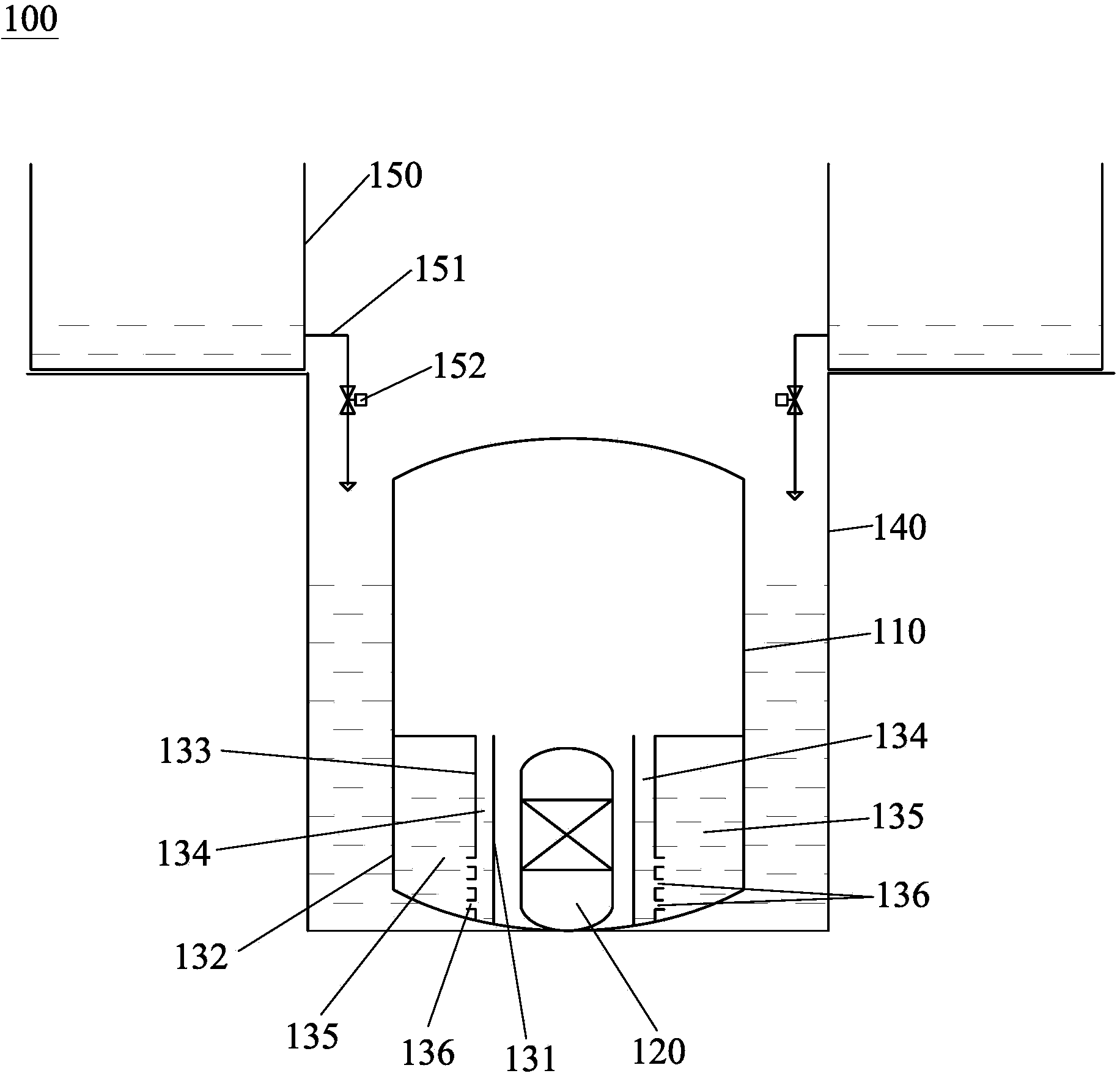

[0022] Embodiments of the present invention will now be described with reference to the drawings, in which like reference numerals represent like elements. The steel containment vessel energy control system 100 provided by the present invention can completely passively discharge heat from the core and containment vessel 110 during the whole process after the accident.

[0023] like figure 1 As shown, the steel containment vessel energy control system 100 provided by the present invention includes a containment vessel 110, a reactor pressure vessel 120 disposed inside the containment vessel 110, a suppression pool 130, and a submerged pool 140 disposed outside the containment vessel 110, An elevated water tank 150, the decompression water pool 130 is arranged in the containment vessel 110 and along the pressure vessel 120, the depressurization water pool 130 has cooling water and communicates with the inner space of the containment vessel 110, the depressurization water pool 13...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com