400 MPa-level tungstenic corrosion-resistant twisted steel and preparation method thereof

A threaded steel bar, 400mpa technology, applied in the field of alloy steel, can solve the problems of limited lifting, achieve simple operation, improve seawater corrosion resistance, good strength and plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

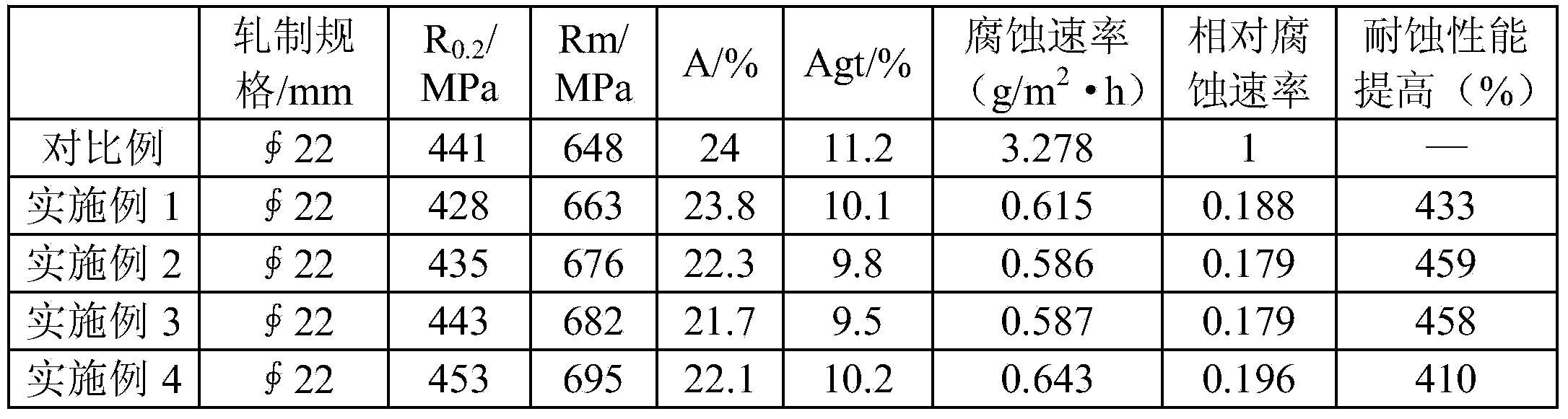

Examples

Embodiment 1

[0024] The reinforcing bar of the present embodiment, each component is as shown in table 1, and its preparation method is:

[0025] The hot metal is desulfurized by the KR method to ensure that the sulfur content in the steel is controlled below 0.01%. Electric furnace smelting, using side blowing for decarburization and dephosphorization, smelting at 1655°C until the carbon content in molten steel is less than 0.05%, and the phosphorus content is less than 0.01%, tapping, adding ferrosilicon, Silicon-manganese alloy deoxidation, adding carbon powder and slagging material; after adding Cr alloy elements, use RH vacuum refining at 1625 °C to carry out oxygen blowing decarburization, and then use LF refining at 1595 °C to deoxidize until the oxygen content in molten steel is 0.002%, add W and other alloying elements after deoxidation; after refining, adopt protective casting, and continuously cast into 150mm×150mm billets; Single-strand rolling, the rolling specification is ∮2...

Embodiment 2

[0027] The reinforcing bar of the present embodiment, each component is as shown in table 1, and its preparation method is:

[0028] The hot metal is desulfurized by the KR method to ensure that the sulfur content in the steel is controlled below 0.01%. Electric furnace smelting, using side blowing for decarburization and dephosphorization, smelting at 1665°C until the carbon content in molten steel is less than 0.06%, and the phosphorus content is less than 0.01%, tapping, and adding ferrosilicon, Silicon-manganese alloy deoxidation, adding carbon powder and slagging material; after adding Cr alloy elements, use RH vacuum refining at 1635 °C to carry out oxygen blowing decarburization, and then use LF refining at 1605 °C to deoxidize until the oxygen content in molten steel is 0.002%, add W and other alloying elements after deoxidation; after refining, adopt protective casting, and continuously cast into 150mm×150mm billets; Single-strand rolling, the rolling specification i...

Embodiment 3

[0030] The reinforcing bar of the present embodiment, each component is as shown in table 1, and its preparation method is:

[0031] The hot metal is desulfurized by the KR method to ensure that the sulfur content in the steel is controlled below 0.01%. Electric furnace smelting, using side blowing for decarburization and dephosphorization, smelting at 1675°C until the carbon content in the molten steel is less than 0.06%, and the phosphorus content is less than 0.01%, tapping, adding ferrosilicon, Silicon-manganese alloy deoxidation, adding carbon powder and slagging material; after adding Cr alloy elements, use RH vacuum refining at 1645 °C to carry out oxygen blowing decarburization, and then use LF refining at 1615 °C to deoxidize until the oxygen content in molten steel is 0.002%, add W and other alloying elements after deoxidation; after refining, adopt protective casting, and continuously cast into 150mm×150mm billets; Single-strand rolling, the rolling specification is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com