Coal combustion catalyst

A catalyst and coal combustion technology, applied in physical/chemical process catalysts, organic compounds/hydrides/coordination complex catalysts, fuels, etc., can solve problems such as threats to human living environment, excessive carbon emissions, and large energy waste , to achieve the effects of environmental protection, reducing exhaust emissions, and reducing coal consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

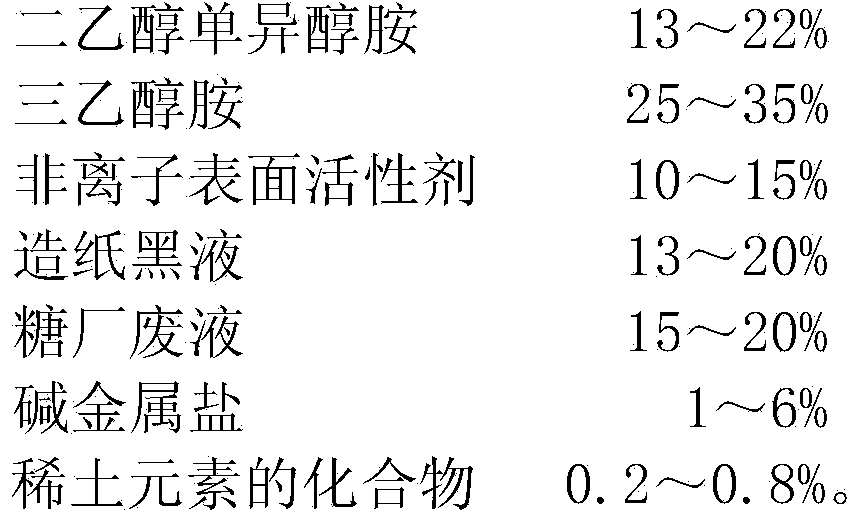

[0028] A kind of coal combustion catalyst, is made of the raw material of following percentage by weight:

[0029]

[0030] Add diethanol monoisoalcoholamine, triethanolamine and polyoxyethylene octylphenol ether into the reaction kettle and stir for 30 minutes, then add papermaking black liquor and sugar factory waste liquor, stir and mix thoroughly, and then add sodium chloride and La 2 o 3 , while continuing to stir, the reactor was heated to 40° C. for 3.5 hours to obtain the desired coal combustion catalyst. Before the catalyst leaves the factory, performance testing should be carried out according to enterprise standards and relevant national and industry standards, including pulverized coal combustion experiments and physical and chemical performance tests of cement. Products that pass the inspection can leave the factory.

Embodiment 2

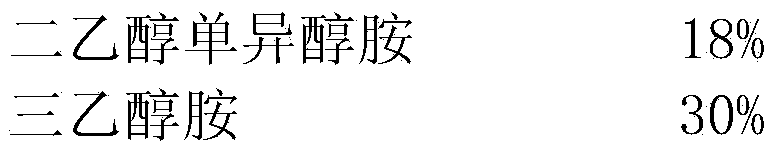

[0032] A kind of coal combustion catalyst, is made of the raw material of following percentage by weight:

[0033]

[0034] Add diethanol monoisoalcoholamine, triethanolamine and polyvinylpyrrolidone into the reaction kettle and stir for 35 minutes, then add papermaking black liquor and sugar factory waste liquor, stir and mix thoroughly, and then add potassium chloride and Y 2 o 3 , while continuing to stir, the reactor was heated to 50° C. for 3 hours to obtain the desired coal combustion catalyst. Before the catalyst leaves the factory, performance testing should be carried out according to enterprise standards and relevant national and industry standards, including pulverized coal combustion experiments and physical and chemical performance tests of cement. Products that pass the inspection can leave the factory.

Embodiment 3

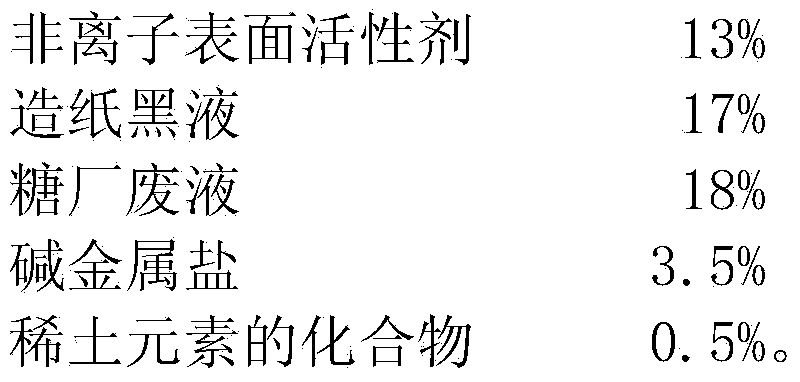

[0036] A kind of coal combustion catalyst, is made of the raw material of following percentage by weight:

[0037]

[0038] Add diethanol monoisoalcoholamine, triethanolamine and polyoxyethylene octylphenol ether into the reaction kettle and stir for 40 minutes, then add papermaking black liquor and sugar factory waste liquor, stir and mix thoroughly, filter and then add sodium chloride and LaMnO 3 , heating the reactor to 60° C. for 2.5 hours while continuing to stir, and the desired coal combustion catalyst can be prepared. Before the catalyst leaves the factory, performance testing should be carried out according to enterprise standards and relevant national and industry standards, including pulverized coal combustion experiments and physical and chemical performance tests of cement. Products that pass the inspection can leave the factory.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com