Method for simultaneously treating inferior heavy oil and producing synthetic gas

A low-quality heavy oil and synthesis gas technology, which is applied in the petroleum industry, refined hydrocarbon oil, bulk chemical production, etc., can solve the problem of reducing the yield of synthesis gas, and achieve the effect of increasing the yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

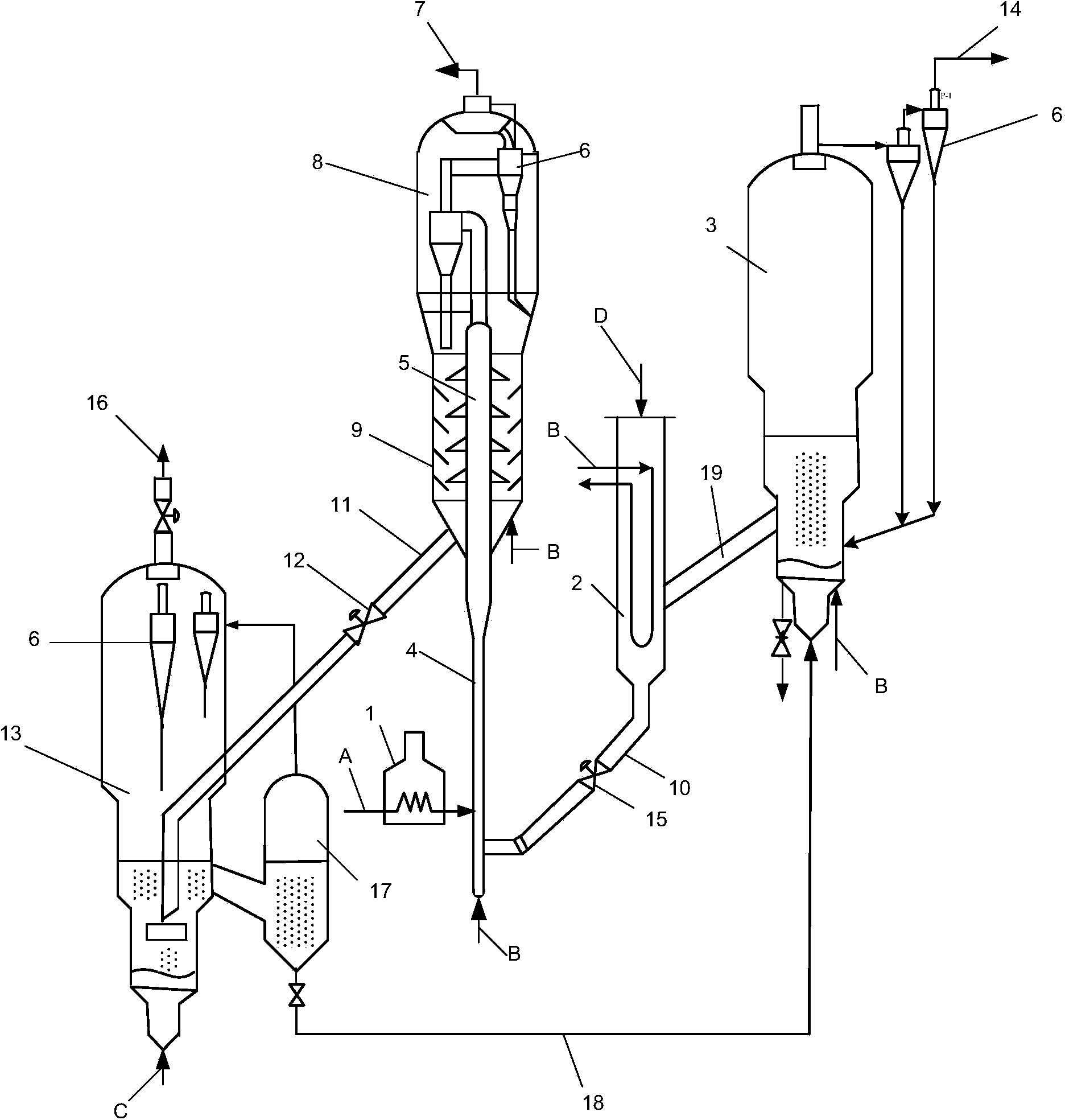

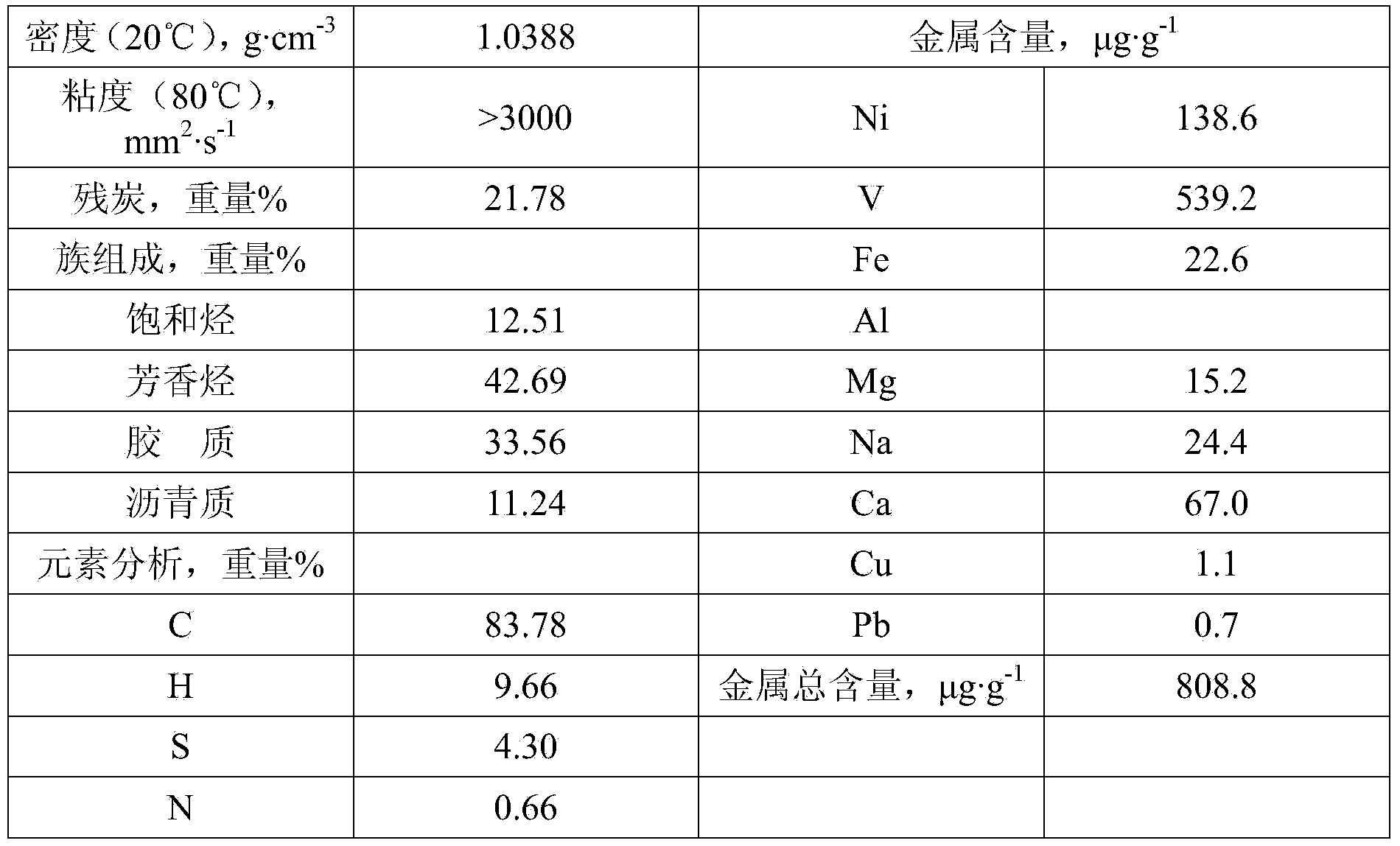

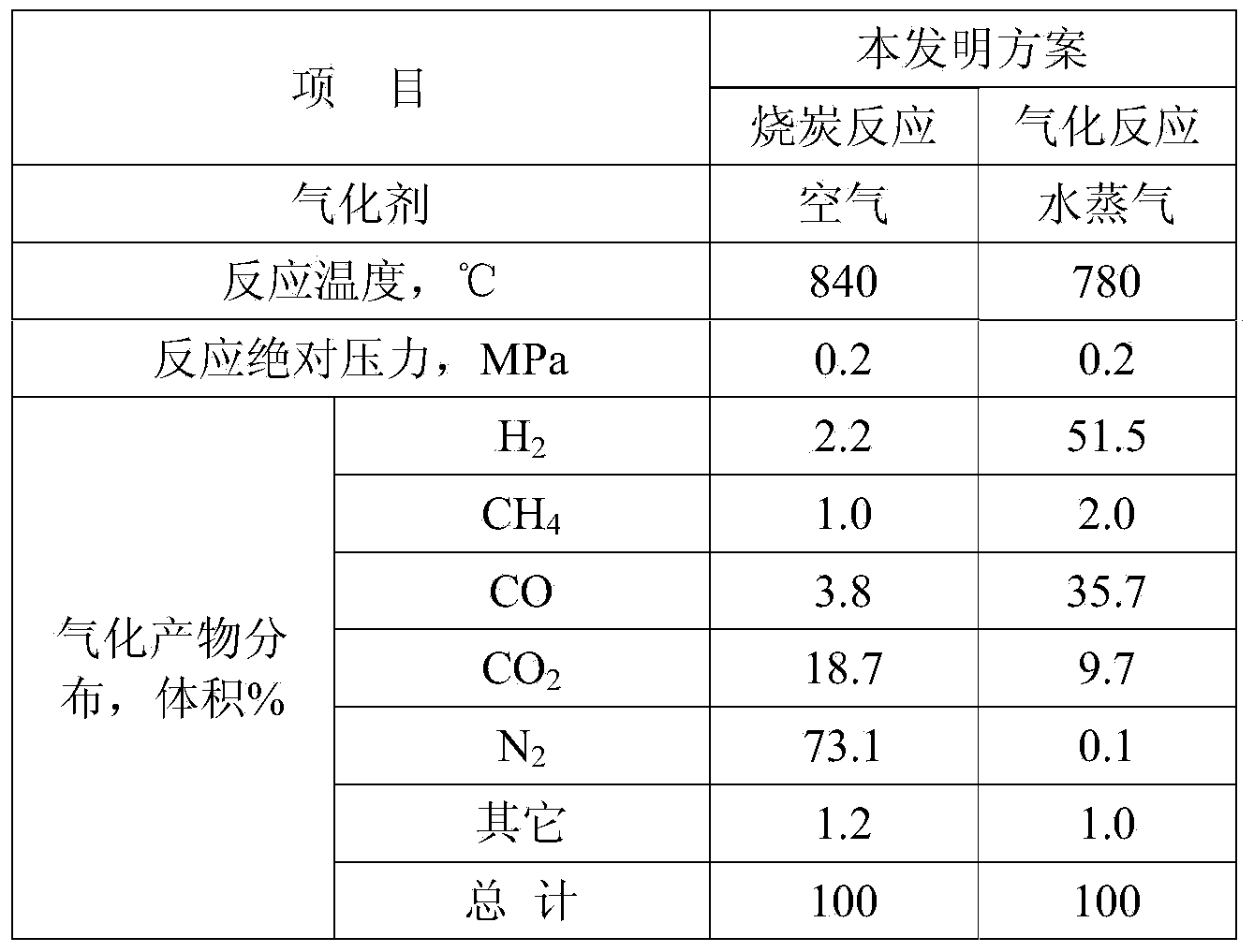

[0052] For verifying the effect of the inventive method, adopt figure 1 In the process flow shown, the Venezuelan vacuum residue is used as the inferior heavy oil raw material A to be processed, and the properties of the vacuum residue are shown in Table 1. The properties of the contact agent used are shown in Table 2. The conditions for the contact reaction between inferior heavy oil raw material A and the contact agent are shown in Table 3, and the composition of the product is shown in Table 4.

[0053] Preheat inferior heavy oil raw material A to 300°C, and then introduce it into riser reactor 4, at a weight hourly space velocity of 5h -1 , the contact reaction with the contact agent is carried out under the condition of agent-oil ratio 7-8, the reaction temperature in the reactor is 480°C, the liquid product yield exceeds 70wt%, the coke yield is close to the residual carbon value of the raw material, and the residual carbon removal rate is close to 90% %, the removal r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com