Graphene-containing composite material as well as preparation method and application thereof

A graphene composite, composite material technology, applied in conductive materials, conductive materials, chemical instruments and methods, etc., can solve the problems of interface bonding conductivity, mechanical strength, flexibility, etc. Easy to operate, easy to operate, and the effect of reducing surface energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] 1) Preparation of sulfonated graphene

[0058] Disperse carboxylated graphene in deionized water, ultrasonically disperse for 2 hours, and prepare a 10 mg / ml carboxylated graphene solution for subsequent use;

[0059] Dissolve 4-anilinesulfonic acid in deionized water to prepare a 20 mg / ml solution for subsequent use;

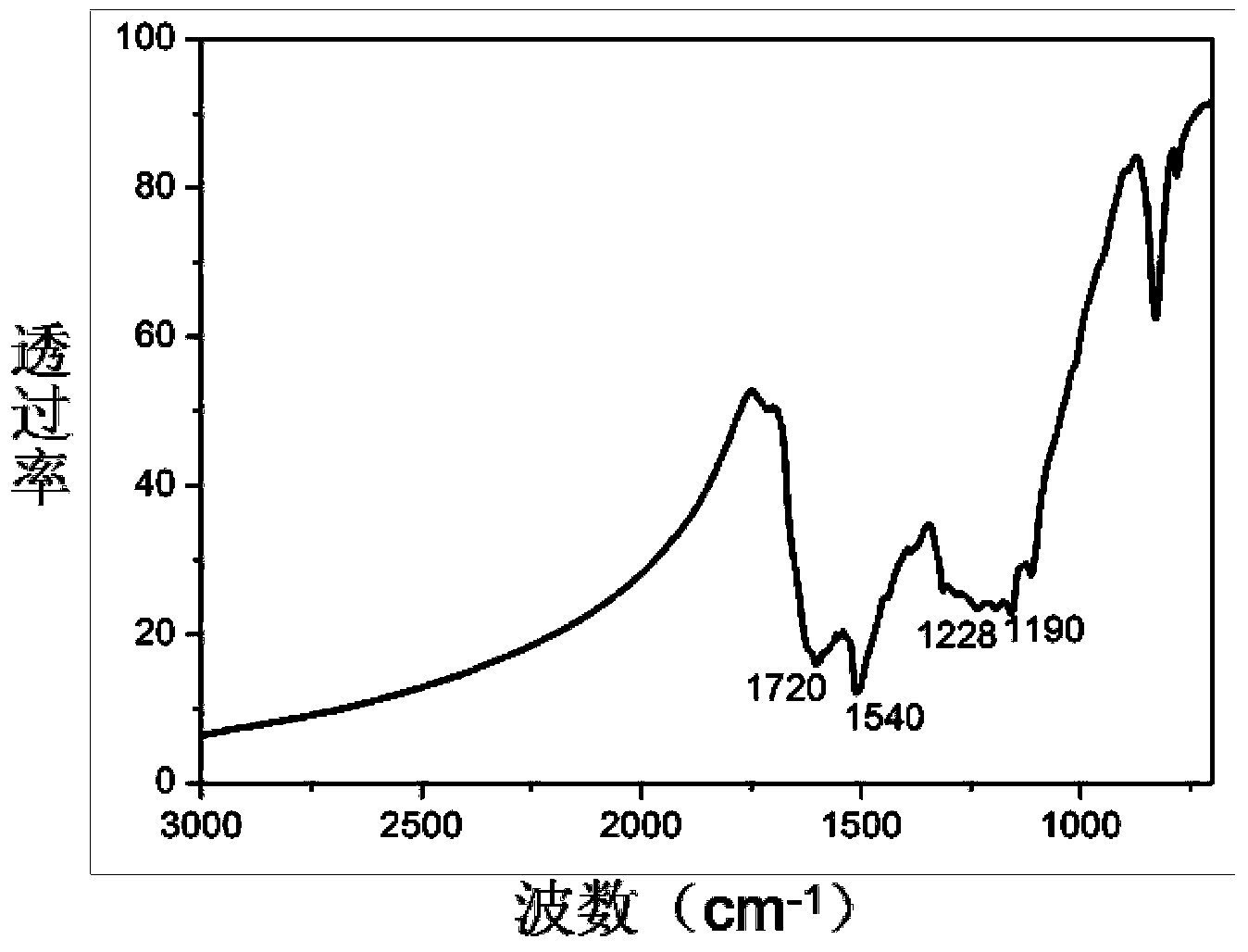

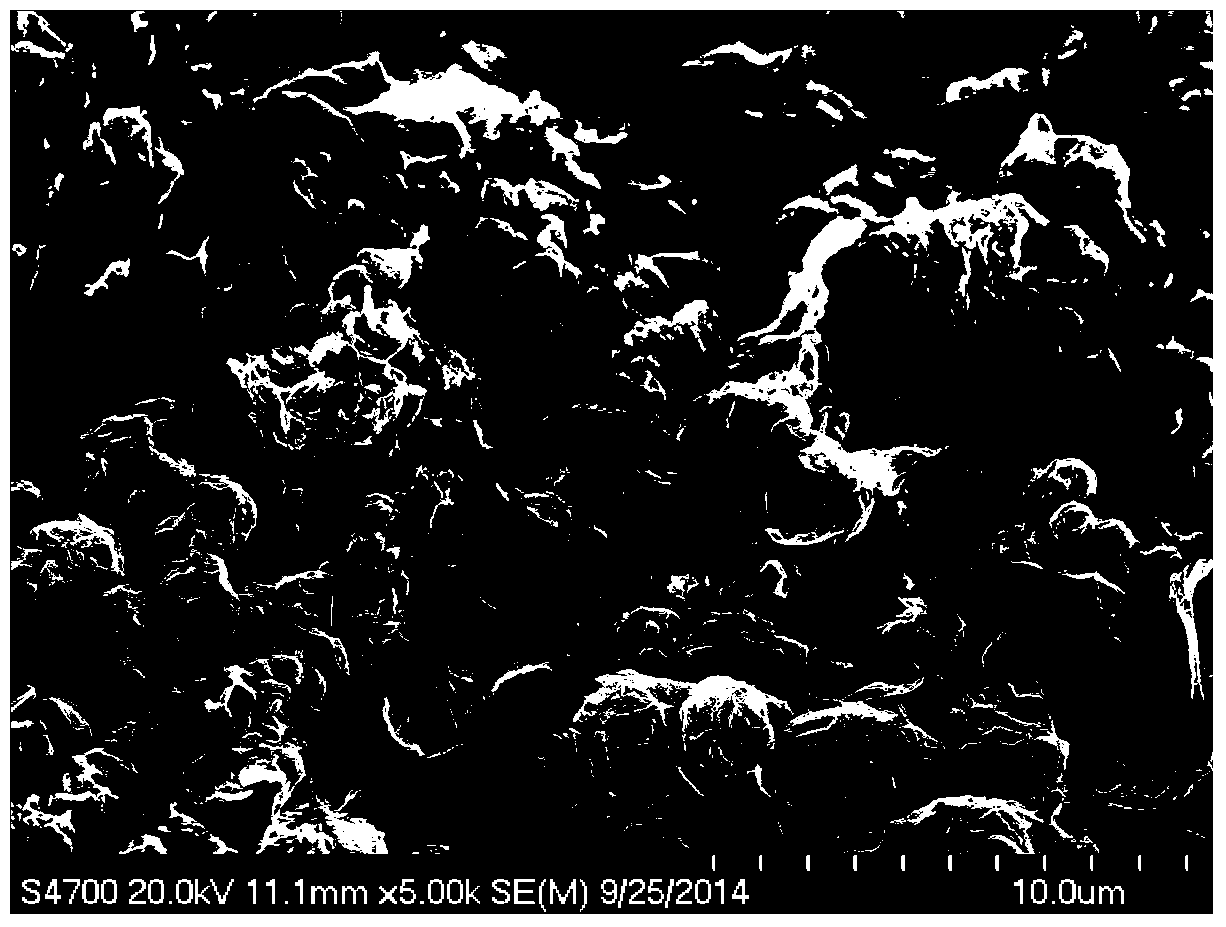

[0060] Mix the two solutions obtained above at a volume ratio of 2:3, add 1-3 drops of dibutyltin dilaurate as a catalyst, and heat and reflux at 95°C for 10 hours, lower the system temperature to 90°C, and then add to the mixed reaction Hydrazine hydrate was added to the system and reacted at a constant temperature for 2 hours, wherein the ratio of the amount of hydrazine hydrate added to the carboxylated graphene was 1.0ml:0.8g. Obtained sulfonated graphene at last, and carried out the pointer analysis of structure morphology and surface group to it, the result is as follows figure 1 , figure 1 It can be seen that sulfonated graphene is a very thin ...

Embodiment 2

[0066] 1) Preparation of sulfonated graphene

[0067] First, weigh a certain amount of carboxylated graphene and disperse it in deionized water, and disperse it ultrasonically for 4 hours to prepare a 10 mg / ml carboxylated graphene solution for subsequent use; secondly, weigh a certain amount of 4-anilinesulfonic acid derivative R-1 was dissolved in deionized water (can be heated to help dissolve), and a 20mg / ml solution was prepared for subsequent use; finally, the two solutions obtained above were mixed at a volume ratio of 2:3, and 1-3 drops of di Dibutyltin laurate was used as a catalyst, and the mixture was heated and refluxed at 95°C for 10 hours, then the temperature of the system was lowered to 90°C, and then a certain amount of hydrazine hydrate was added to the mixed reaction system, and the reaction was carried out at constant temperature for 2 hours. Obtain sulfonated graphene, wherein the ratio of the addition of the hydrazine hydrate to the carboxylated graphene ...

Embodiment 3

[0071] 1) Preparation of sulfonated graphene

[0072] First, weigh a certain amount of carboxylated graphene and disperse it in deionized water, and disperse it ultrasonically for 6 hours to prepare a 10 mg / ml carboxylated graphene solution for subsequent use; secondly, weigh a certain amount of 4-anilinesulfonic acid derivative R-2 was dissolved in deionized water (can be heated to help dissolve), and a 20mg / ml solution was prepared for subsequent use; finally, the two solutions obtained above were mixed at a volume ratio of 2:3, and 1-3 drops of di Dibutyltin laurate was used as a catalyst, and the mixture was heated and refluxed at 95°C for 10 hours, then the temperature of the system was lowered to 90°C, and then a certain amount of hydrazine hydrate was added to the mixed reaction system, and the reaction was carried out at constant temperature for 2 hours. Obtain sulfonated graphene, wherein the ratio of the addition of the hydrazine hydrate to the carboxylated graphene ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com