Cost-saving preparation method of p-nitrobenzyl alcohol

A cost-saving technology for p-nitrobenzyl alcohol, which is applied in the field of synthesis technology of p-nitrobenzyl alcohol, and achieves the effects of low preparation cost, simple process and simple reaction system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

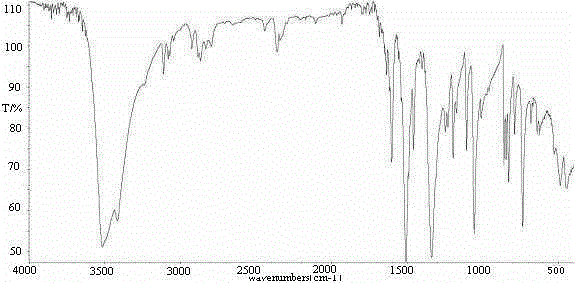

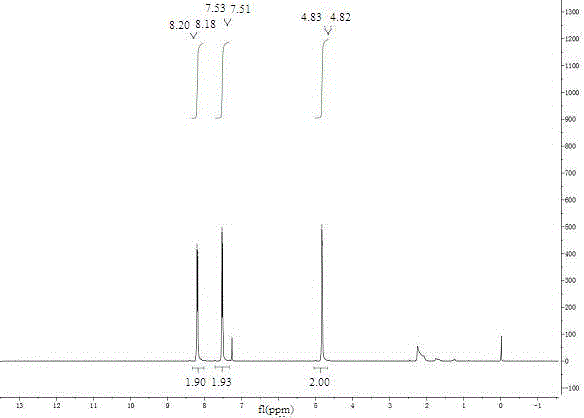

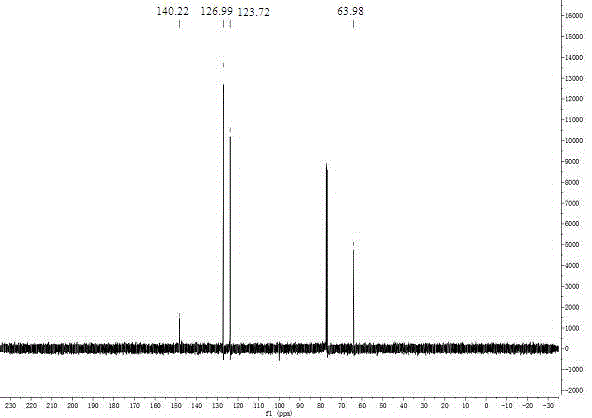

Image

Examples

Embodiment 1

[0018] Preparation of p-nitrobenzyl chloride

[0019] Take 1mol of p-nitrotoluene, 5mmol of benzoyl peroxide, and 1mol of carbon tetrachloride into the reaction flask, heat to 150°C and reflux at a stirring speed of 250-500r / min, and introduce chlorine gas, and the time is controlled at 1- 2h; after adding, continuously sample during the reaction and carry out chromatographic analysis. When the yield of p-nitrobenzyl chloride reaches about 50%, the raw material p-nitrotoluene is distilled out at 180° C. The total yield of nitrobenzyl chloride is increased to 88%. At the same time, the hydrogen chloride gas generated during the reaction is discharged to the tail gas absorption system to be absorbed into hydrochloric acid by water. Finally, the crude product of nitrobenzyl chloride is crystallized with 3mol absolute ethanol as a solvent Purification, the product with a purity higher than 99.0% can be obtained.

Embodiment 2

[0021] Preparation of p-nitrobenzyl chloride

[0022] Take 1mol of p-nitrotoluene, 4mmol of benzoyl peroxide, and 1.2mol of carbon tetrachloride into the reaction flask, heat to 160°C and reflux at a stirring speed of 250-500r / min, and feed in chlorine gas for a time of 1 -2h; After adding, keep sampling during the reaction and carry out chromatographic analysis. When the yield of p-nitrobenzyl chloride reaches about 37%, the raw material p-nitrotoluene is distilled out at 190°C and chlorinated again. Repeat the above steps to make The total yield of p-nitrobenzyl chloride is increased to 89%. At the same time, the hydrogen chloride gas produced in the reaction process is discharged to the tail gas absorption system to be absorbed into hydrochloric acid with water, and finally the crude product of p-nitrobenzyl chloride is used as a solvent with 3mol absolute ethanol Crystallization and purification can obtain products with a purity higher than 98.0%.

Embodiment 3

[0024] Preparation of p-nitrobenzyl chloride

[0025] Take 1mol of p-nitrotoluene, 6mmol of benzoyl peroxide, and 1.3mol of carbon tetrachloride into the reaction flask, heat to 150°C and reflux at a stirring speed of 250-500r / min, feed chlorine gas, and control the time at 1 -2h; After the addition, the reaction is continuously sampled for chromatographic analysis. When the yield of p-nitrobenzyl chloride reaches about 40%, the raw material p-nitrotoluene is distilled out by steam distillation at 100°C and then chlorinated again. Repeat the above steps to make The total yield of p-nitrobenzyl chloride is increased to 86%. At the same time, the hydrogen chloride gas produced in the reaction process is discharged to the tail gas absorption system to be absorbed into hydrochloric acid with water. Finally, the crude product of p-nitrobenzyl chloride is used as a solvent with 3mol absolute ethanol Crystallization and purification can obtain products with a purity higher than 99.0%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com