Biological curing and preservation method of green plums

A biological and green plum technology is applied in the field of biological pickling and preservation of green plums, which can solve the problems such as the loss of green plum flavor, and achieve the effects of not softening the pulp, improving hardness and brittleness, and not wrinkling the fruit.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A biological pickling and preservation method for green plums, comprising the following steps:

[0029] (1) Put 10 kg of complete, non-rotten 6-7 mature turquoise green plums in a ventilated water tank to clean them, remove them and place them in a vibrating sieve to drain until no water drops adhere to the surface of the fruit.

[0030] (2) Lay the cleaned greengage fruit on the mesh conveyor belt, spray superheated steam at 110°C up and down simultaneously, and the processing time is 15 seconds.

[0031] (3) Pour the green plum fruit of the above-mentioned step (2) into 20L of alcohol solution with a concentration of 75% (V / V) and soak for 4 to 5 minutes. alcohol solution.

[0032] (4) Preparation of biological pickling solution:

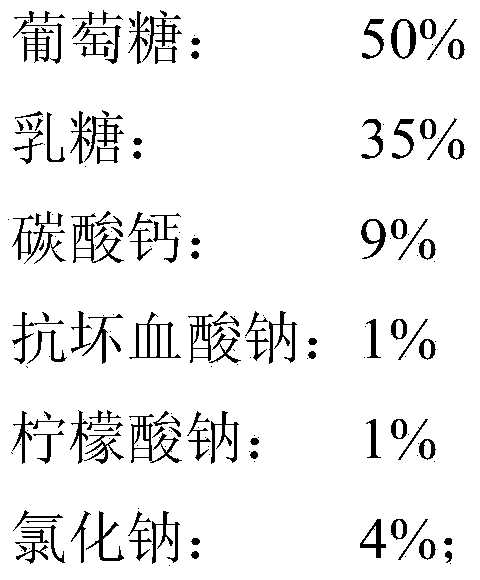

[0033] A, 0.48kg biological marinade 1 (made up of 240g glucose, 168g lactose, 43.2g calcium carbonate, 4.8g sodium ascorbate, 4.8g sodium citrate and 19.2g sodium chloride) is dissolved in water and is made into 6kg solution, 0.3kg of b...

Embodiment 2

[0038] A biological pickling and preservation method for green plums, comprising the following steps:

[0039] (1) Put 5 kg of complete, non-rotten 6-7 mature turquoise green plums in a ventilated water tank to clean them, remove them and put them in a vibrating sieve to drain until no water drops adhere to the surface of the fruit.

[0040] (2) Spread the cleaned greengage fruit on the mesh conveyor belt, spray superheated steam at 105°C up and down simultaneously, and the processing time is 40 seconds.

[0041] (3) Pour the green plum fruit of the above-mentioned step (2) into 10L concentration and soak in the alcohol solution of 75% (V / V) for 4 to 5 minutes. alcohol solution.

[0042] (4) Preparation of biological pickling solution:

[0043] A, 0.36kg biological marinade 1 (made up of 180g glucose, 126g lactose, 32.4g calcium carbonate, 3.6g sodium ascorbate, 3.6g sodium citrate and 14.4g sodium chloride) is dissolved in water and is made into 3kg solution, 0.225kg of bi...

Embodiment 3

[0048]A biological pickling and preservation method for green plums, comprising the following steps:

[0049] (1) Put 20 kg of complete, non-rotten 6-7 mature turquoise green plums in a ventilated water tank to clean them, remove them and put them in a vibrating sieve to drain until no water drops adhere to the surface of the fruit.

[0050] (2) Lay the cleaned greengage fruit on the mesh conveyor belt, spray superheated steam at 108°C up and down simultaneously, and the processing time is 25 seconds.

[0051] (3) Pour the green plum fruit of the above-mentioned step (2) into 40L concentration and soak in the alcohol solution of 75% (V / V) for 4 to 5 minutes. alcohol solution.

[0052] (4) Preparation of biological pickling solution:

[0053] A, 1.2kg biological marinade 1 (consisting of 600g glucose, 420g lactose, 108g calcium carbonate, 12g sodium ascorbate, 12g sodium citrate and 48g sodium chloride) is dissolved in water to form a 12kg solution, and 0.75kg biological Mar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com