A kind of sludge treatment equipment and method thereof

A sludge treatment and sludge technology, applied in the field of sludge treatment equipment, can solve the problems of high water content in sludge, poor engineering properties, and large engineering hidden dangers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

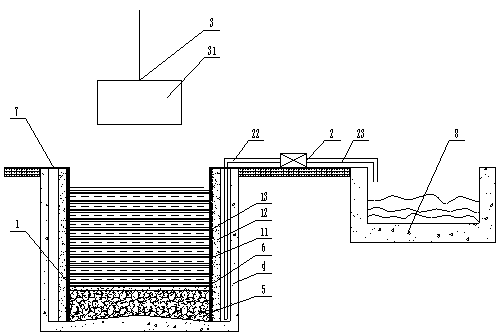

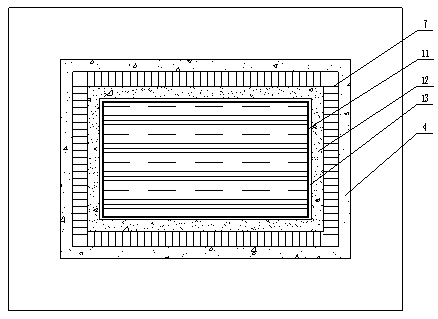

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings.

[0030] During specific implementation: if figure 1 and figure 2 As shown, a sludge treatment equipment includes a water-permeable layer assembly 1 and a suction device 2. The water-permeable layer assembly 1 encloses a sludge placement space with an upward opening, and a water accumulation space is provided outside the water-permeable layer assembly 1 in the circumferential direction. , the suction device 2 includes a water pump, the inlet end of the water pump is connected to the water accumulation space, and also includes a dynamic compaction device 3 arranged outside the mud storage space, and the dynamic compaction device 3 includes a The dynamic tamping hammer 31 above the storage space can move down along the depth direction of the silt storage space into the silt storage space for dynamic tamping.

[0031]In this technical solution, the silt is plac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com