Catalyst composition for exhaust gas purification and exhaust gas purifying catalyst for automobiles

A technology of exhaust gas purification and catalyst, which is applied in the direction of catalyst activation/preparation, heterogeneous catalyst chemical elements, physical/chemical process catalysts, etc. It can solve the problems of NOx performance reduction and damage to Pd performance, and achieve high purification performance and stable supply , the effect of effective use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0125] (1) Preparation method of catalyst composition

[0126] In order to prepare the exhaust gas-purifying catalyst composition of the present invention, when α-alumina is supported on a zirconia-based base material, the following method can be used, for example.

[0127] (Process 1)

[0128] Mix the slurry containing α-alumina particles and the slurry containing zirconia-based base material, and cover and load α-alumina on the oxidized on the zirconium base material. As the slurry, in addition to the above, slurry obtained by wet pulverizing α-alumina until it becomes fine particles using a pulverizing device such as a bead mill, or using a pulverizing device such as a bead mill A slurry obtained by wet pulverizing materials until they reach a specified particle size.

[0129] (Craft 2)

[0130] In process 1, boehmite, γ-alumina, etc. are used instead of α-alumina, which are covered on the zirconia-based base material, and then the alumina-supported zirconia-based base ...

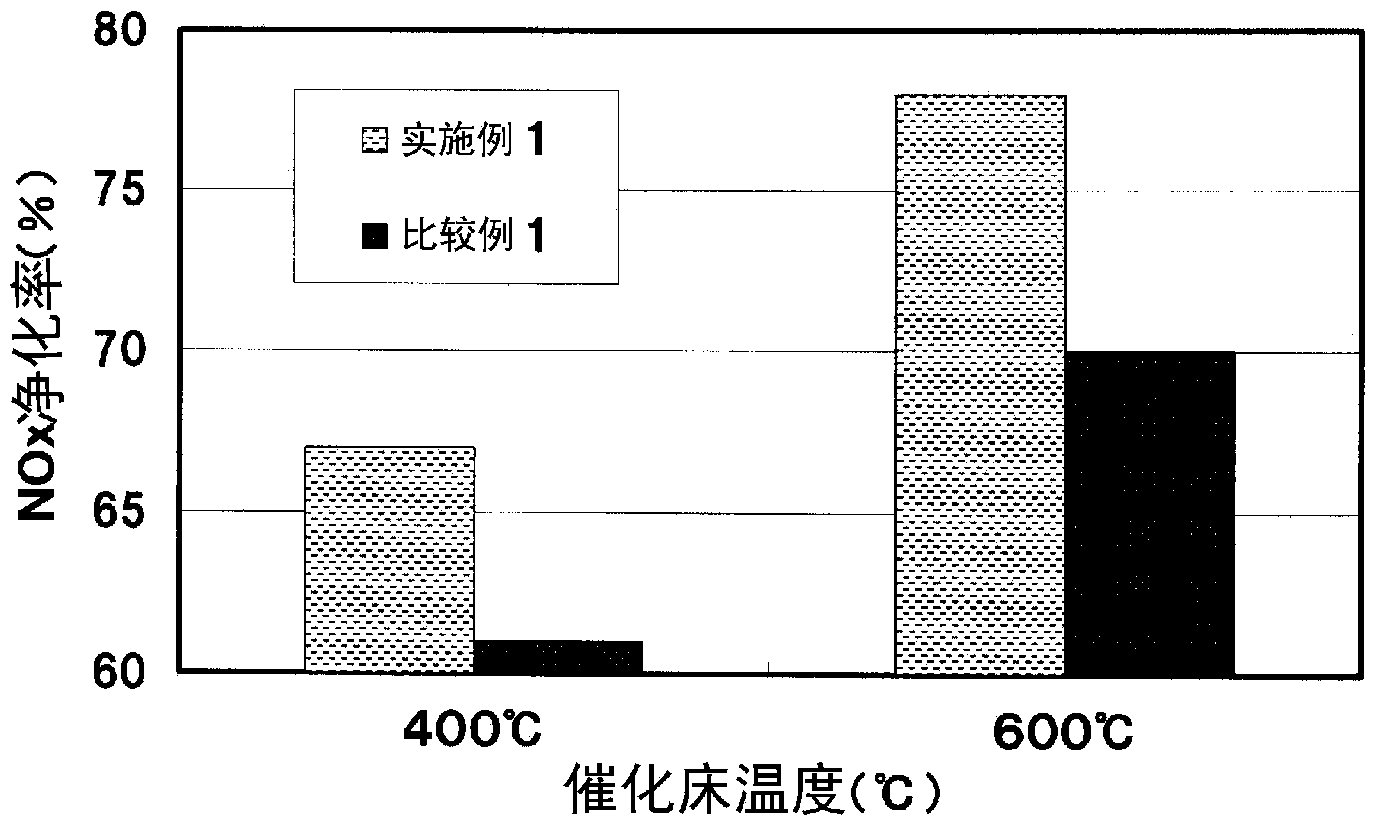

Embodiment 1

[0168] Set the BET specific surface area to 7m 2 300 g of α-alumina powder A per g and water were put into a ball mill, and α-alumina was ground until the average particle diameter (D50) became 200 nm, thereby obtaining slurry α.

[0169] Operate in the same way, by making the BET specific surface area 60m 2 / g, neodymium oxide zirconium oxide powder B (Nd 2 o 3 :La 2 o 3 :ZrO 2 =17.5:7.5:75) 690 g and water were put into a ball mill and milled until the average particle diameter (D50) of neodymium oxide and zirconium oxide became 3 μm, thereby obtaining slurry β.

[0170] Slurry α and slurry β were added in a ratio of 30:69 according to the solid content ratio and stirred and mixed, then the mixed slurry was sprayed and dried by a spray dryer, and the obtained powder was calcined at 600°C for 2 hours, Thus, 30.3% by weight α-alumina-supported neodymium-zirconia powder a {average particle diameter (D50): 10 μm} was obtained.

[0171] An aqueous solution of Rh nitrate wa...

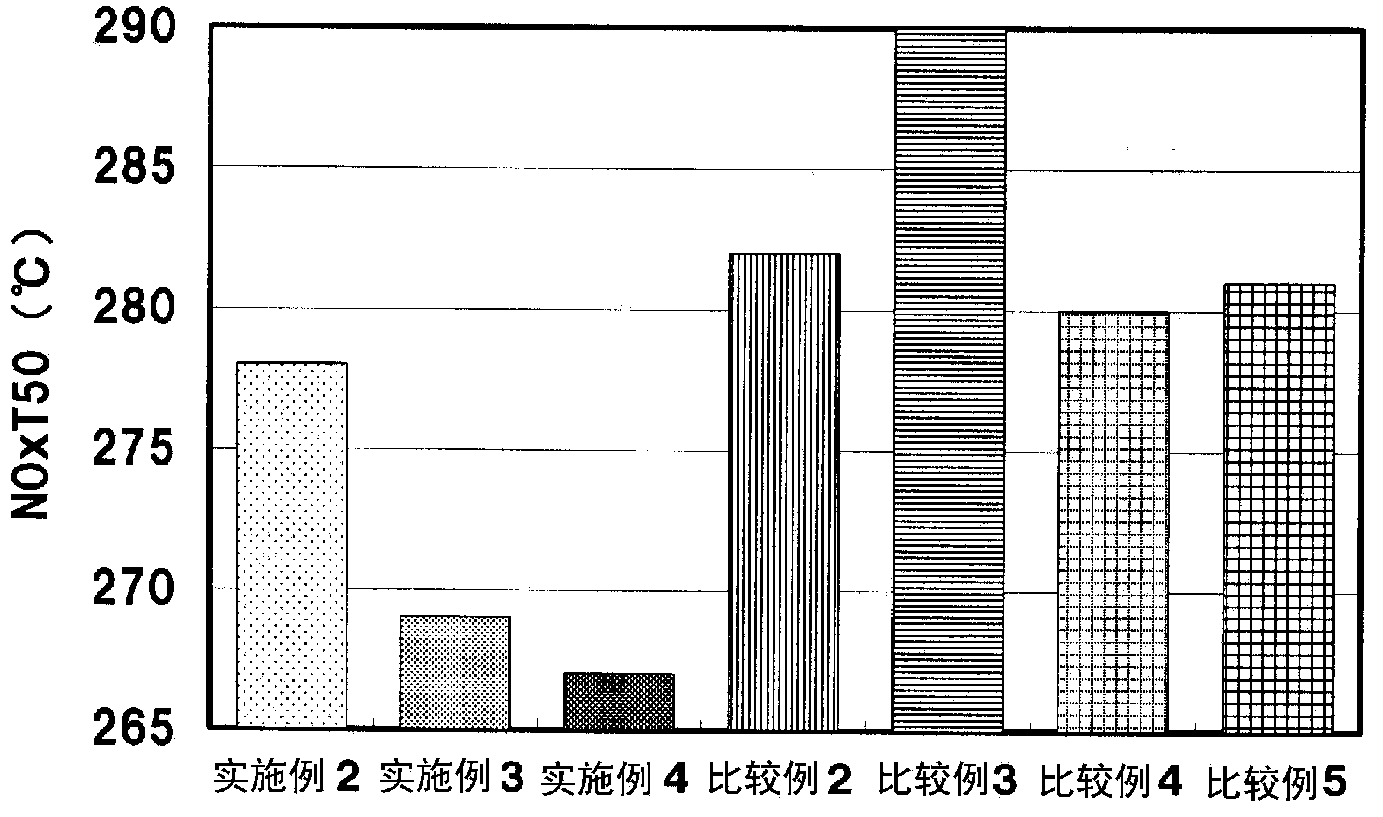

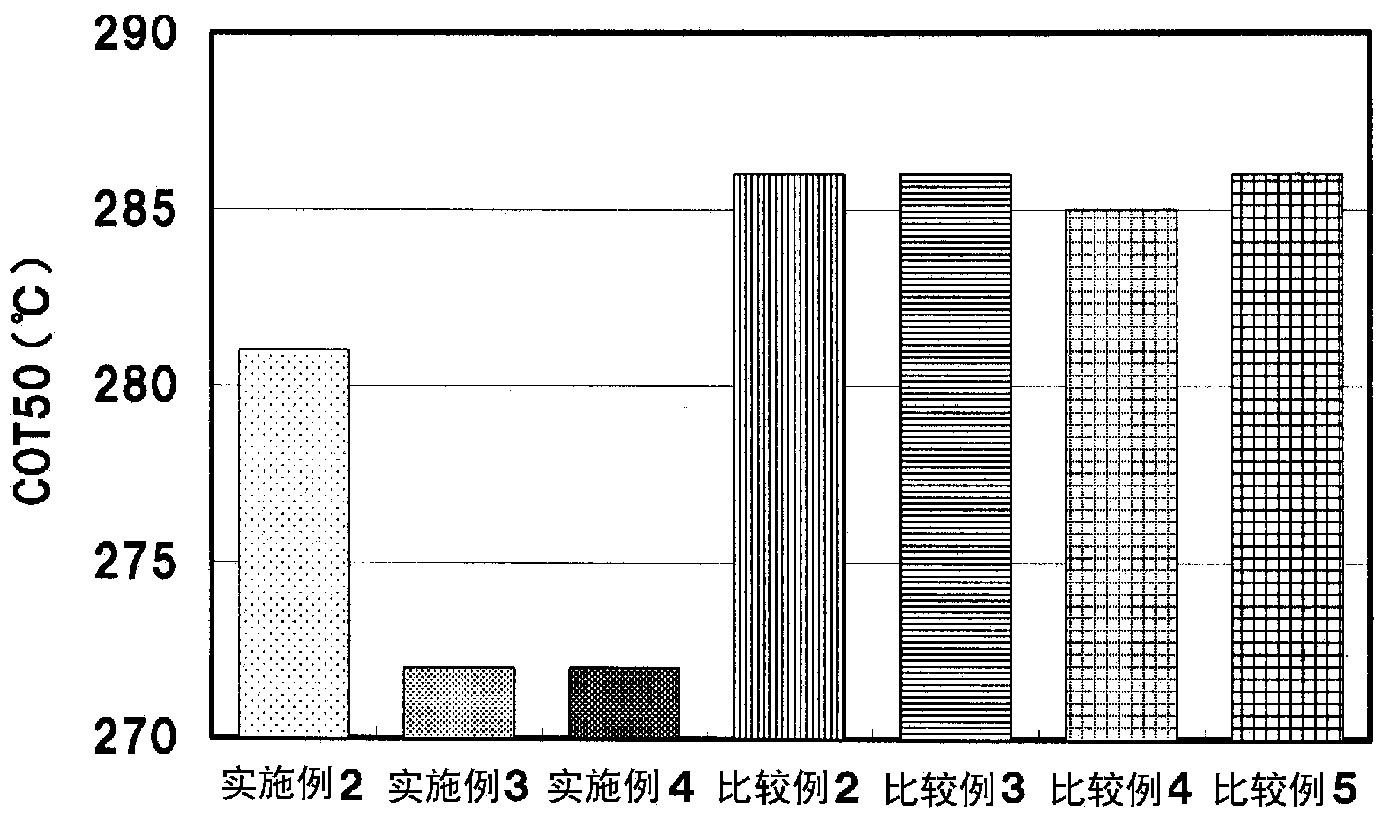

Embodiment 2

[0185] =Lower=

[0186] The aqueous solution of Pd nitrate is impregnated and supported on BET with a specific surface area of 150m 2 / g and 993.8 g of γ-alumina powder C with a pore diameter of 23 nm, thereby obtaining 0.62% by weight Pd-supported alumina powder c.

[0187] In the same manner, the Pd nitrate solution was impregnated and supported on the BET specific surface area of 73m so that the precious metal conversion would be 3.5g. 2 / g, cerium oxide zirconium oxide powder D(CeO 2 :La 2 o 3 :ZrO 2 =45:10:45) 996.5 g, thereby obtaining 0.35% by weight Pd-supported ceria / zirconia powder d.

[0188] Furthermore, 0.62 wt% Pd supported alumina powder c 500g, 0.35 wt% Pd supported ceria·zirconia powder 400g, BET specific surface area 5m 2 150 g of barium sulfate / g and 210 g of γ-alumina powder C were dispersed in water, mixed with a stirrer or the like to obtain slurry γ.

[0189] Next, the flow-through cordierite carrier {600Cell / inch 2 (930k / m 2 ) / 4mil (0.1mm),...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com