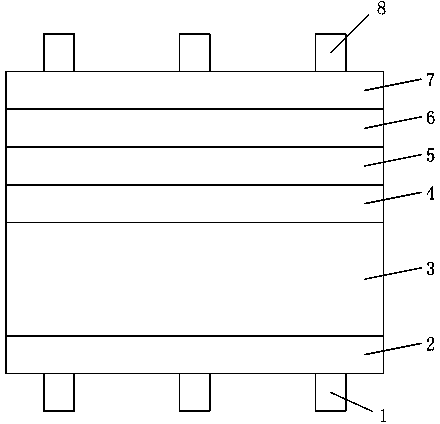

Solar cell with potential induction decay resistance and method for manufacturing solar cell

A potential-induced attenuation and solar cell technology, applied in the field of solar cells, can solve the problems of unsatisfactory sodium ion blocking effect, unsatisfactory anti-PID performance, and reduced photoelectric conversion efficiency of solar cells, so as to improve photoelectric conversion efficiency and improve Anti-PID effect, effect of improving anti-PID performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

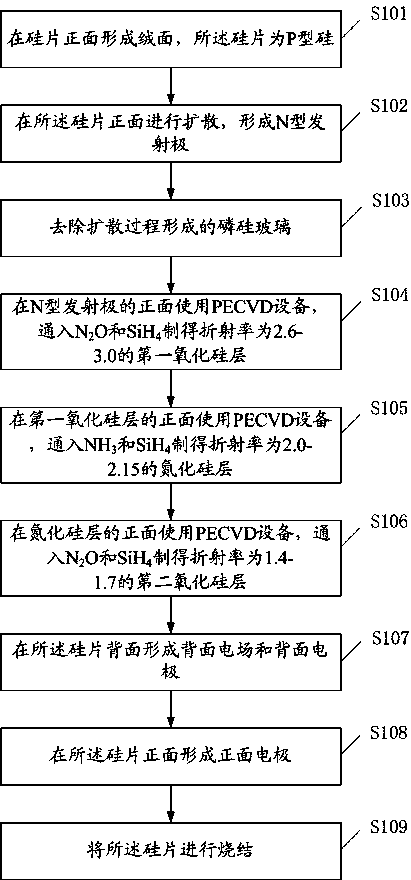

[0045] see figure 2 , the invention provides a method for preparing a solar cell resistant to potential-induced decay, comprising:

[0046] S101, forming a textured surface on the front surface of the silicon wafer, where the silicon wafer is P-type silicon.

[0047] The textured surface of the silicon chip adopts HF and / or HNO 3 solution to form an ideal suede structure and reduce reflectivity.

[0048] S102, performing diffusion on the front surface of the silicon wafer to form an N-type emitter.

[0049] The N-type emitter can be formed by methods such as thermal diffusion or ion implantation, wherein the diffusion of the silicon wafer is preferably made of phosphorus oxychloride.

[0050] S103, removing the phosphosilicate glass formed in the diffusion process.

[0051] Removing the phosphosilicate glass is beneficial to ensure the photoelectric conversion efficiency of the battery.

[0052] S104, use PECVD equipment on the front of the N-type emitter, and pass throu...

Embodiment 1

[0067] Forming a suede surface on the front side of the silicon wafer, the silicon wafer is P-type silicon;

[0068] Diffusion is performed on the front side of the silicon wafer to form an N-type emitter;

[0069] Removal of phosphosilicate glass formed by the diffusion process;

[0070] Use PECVD equipment on the front of the N-type emitter, pass N 2 O and SiH 4 A first silicon oxide layer with a refractive index of 2.6 and a thickness of 1nm was prepared, wherein the reaction temperature was 350°C, the deposition time was 10s, and the N 2 O and SiH 4 The flow ratio is 0.1:3;

[0071] Use PECVD equipment on the front side of the first silicon oxide layer, pass NH 3 and SiH 4 A silicon nitride layer with a refractive index of 2.10 and a thickness of 50nm was prepared, wherein the reaction temperature was 380°C, the deposition time was 500s, and SiH 4 and NH 3 The flow ratio is 0.1:1;

[0072] Use PECVD equipment on the front side of the silicon nitride layer, pass N ...

Embodiment 2

[0077]Forming a suede surface on the front side of the silicon wafer, the silicon wafer is P-type silicon;

[0078] Diffusion is performed on the front side of the silicon wafer to form an N-type emitter;

[0079] Removal of phosphosilicate glass formed by the diffusion process;

[0080] Use PECVD equipment on the front of the N-type emitter, pass N 2 O and SiH 4 A first silicon oxide layer with a refractive index of 2.65 and a thickness of 3nm was prepared, wherein the reaction temperature was 380°C, the deposition time was 50s, and N 2 O and SiH 4 The flow ratio is 0.5:5;

[0081] Use PECVD equipment on the front side of the first silicon oxide layer, pass NH 3 and SiH 4 A silicon nitride layer with a refractive index of 2.11 and a thickness of 52nm was prepared, wherein the reaction temperature was 400°C, the deposition time was 600s, and SiH 4 and NH 3 The flow ratio is 0.2:1;

[0082] Use PECVD equipment on the front side of the silicon nitride layer, pass N 2 O...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com