A detection device and detection method for a high-precision embedded multi-terminal plug connector

A detection method and detection device technology, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of low automation level and difficulty in realization, and achieve the effect of less material waste, avoiding wear and tear, and high-precision detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The specific implementation manners of the present invention will be described below in conjunction with the accompanying drawings.

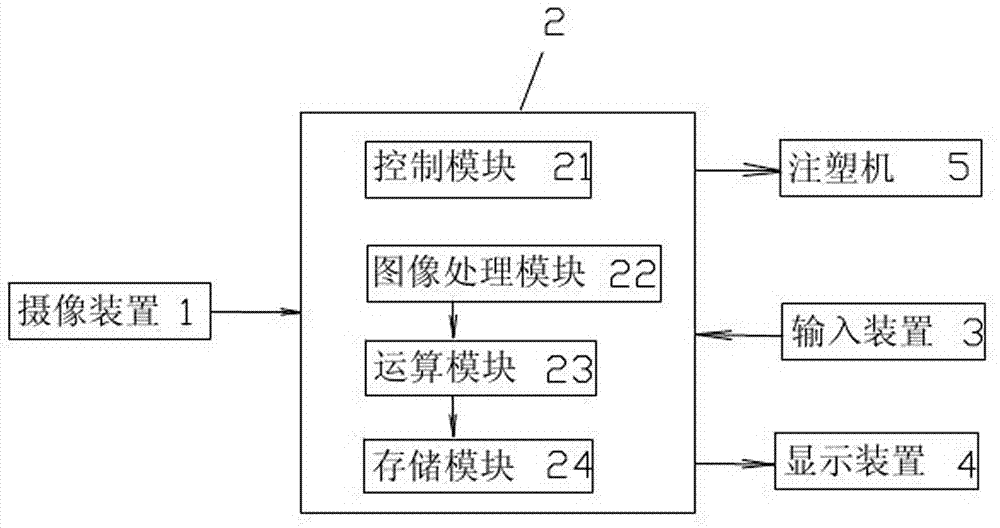

[0038] like figure 1 As shown, a detection device for a high-precision embedded multi-terminal plug connector, including

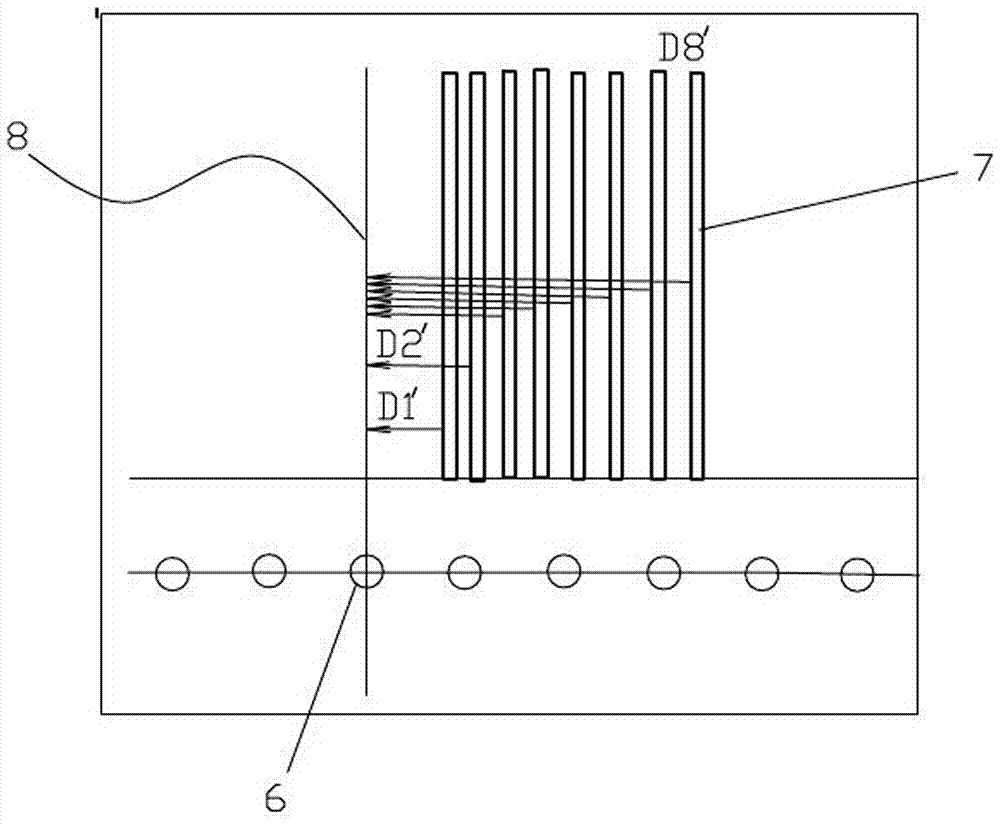

[0039] The camera device 1 is set in cooperation with the mold for producing high-precision embedded molding multi-terminal plug connectors, and is used to photograph the terminals accommodated in the accommodation cavity of the mold. The mold includes multiple accommodation cavities, and the terminals are accommodated in one-to-one correspondence in each cavity of the mold.

[0040]It also includes a central processing unit 2, and the central processing unit 2 is electrically connected to the camera device 1 for processing images and data input from the camera device, as well as instructions and data input from the operating device 3; the central processing unit 2 is also connected with the production high Precisio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com