Method for preparing antimicrobial textiles by using electronic radiation technology

An antibacterial textile, electronic radiation technology, applied in textiles and papermaking, fiber types, fiber treatment, etc., can solve the problems of increased finishing and wastewater treatment costs, uncontrollable factors and side reactions, and difficult product quality control. Control, high product yield, antibacterial performance improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0043] Dissolve 0.5mol methacrylamide and 0.05mol initiator in 100ml water, and react at 70°C for 5min to make oligomer antibacterial liquid. The natural fiber textiles to be treated (cotton fabrics, purchased from Zhejiang Guandong Printing and Dyeing Garment Co., Ltd.) were processed by 100KGy electron radiation, immersed in the above antibacterial solution for 6 hours, taken out, and dried in a dryer at 60°C for 30 minutes. Wash its surface with a large amount of deionized water, after drying, soak it in a 0.5% sodium hypochlorite solution by mass percentage, take it out after soaking for 1 hour, wash it with a large amount of water, and dry it in a dryer at 45°C for 1 hour. Prepare antibacterial pure cotton fabric. The available chlorine content of the antibacterial pure cotton fabric was measured by iodometric method.

Embodiment 3

[0049] Dissolve 0.5mol of acrylamide (structure as shown below) and 0.025mol of initiator in 100ml of water, react at 60°C for 30min, and make a working solution. After the synthetic fiber (polypropylene nonwoven fabric) to be treated is irradiated by 80KGy, immersed in the above working solution for 2 hours, the polypropylene fabric is taken out, and its surface is cleaned with a large amount of deionized water. After drying, soak it in a solution of 0.5% sodium hypochlorite by mass, take it out after soaking for 1 hour, wash it with plenty of water, and dry it in a dryer at 45°C for 1 hour to obtain an antibacterial polypropylene fabric. The available chlorine content of the antibacterial polypropylene fabric measured by iodometric method is 0.14%.

[0050]

[0051] 2. Example of co-radiation process

[0052] 1. Embodiment 4

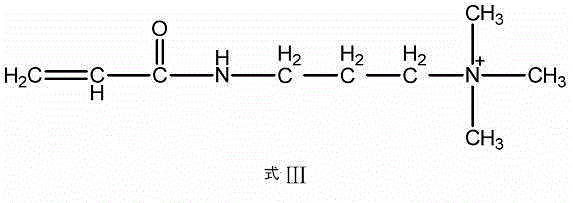

[0053] Immerse the cotton fabric in an aqueous solution containing 10% 3-acrylamidopropyltrimethylammonium chloride (structure as shown in formul...

Embodiment 5

[0056] Immerse the cotton fabric in 5% 1,1,2,2-tetramethylpiperidinol acrylate (structure as shown in formula IV) / acrylic acid solution, take it out and roll it (rolling ratio 120%), After 65KGy electron radiation, place it in a dryer at 60°C for 30 minutes. After drying, soak it in 0.5% sodium hypochlorite solution by mass percentage, take it out after soaking for 1 hour, wash it with plenty of water, and dry it in a dryer at 45°C for 1 hour to obtain antibacterial cotton fabric. The available chlorine content of the antibacterial cotton fabric measured by iodometric method is 0.23%.

[0057]

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com