Iron-group carbide nano crystal-graphene nanoribbon composite material as well as preparation and application thereof

A graphene nanobelt and iron group carbide technology, applied in the field of carbon nanomaterials, achieves the effects of uniform distribution, high degree of crystallization and simplified process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

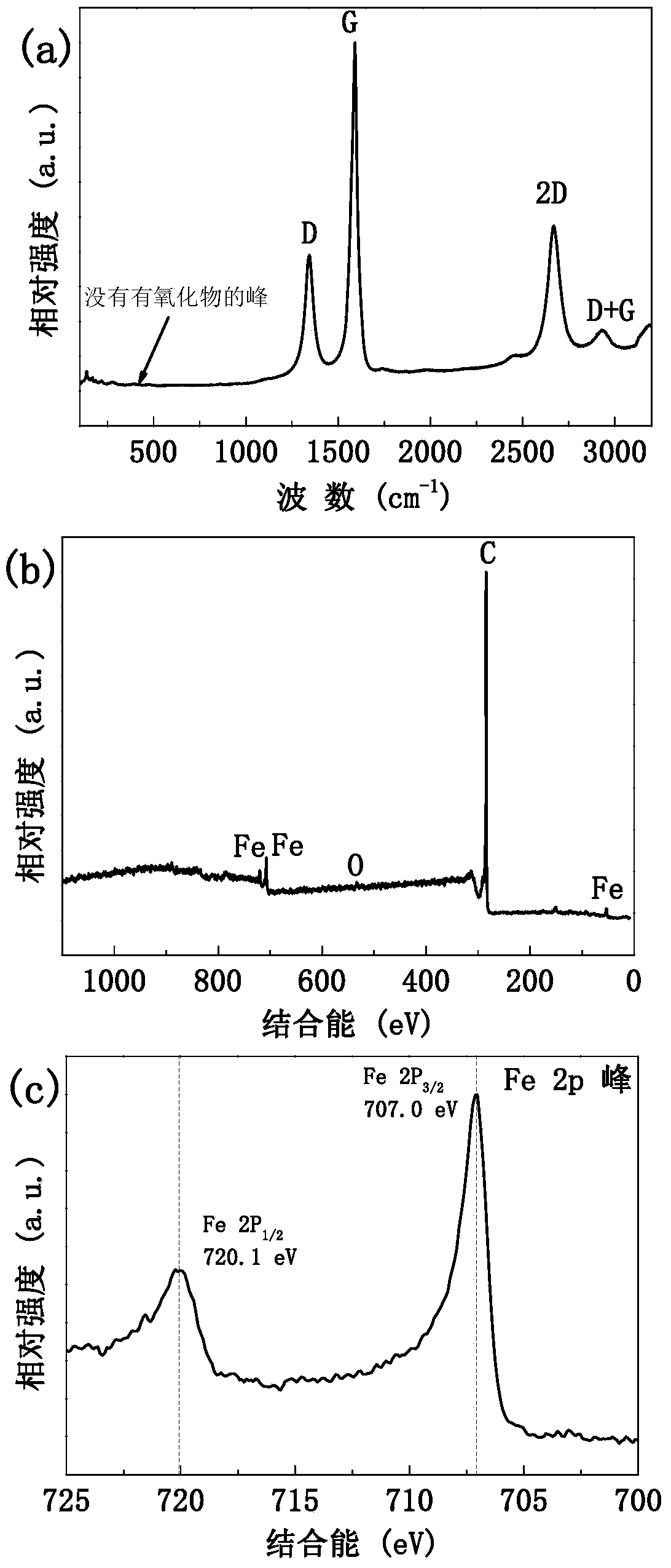

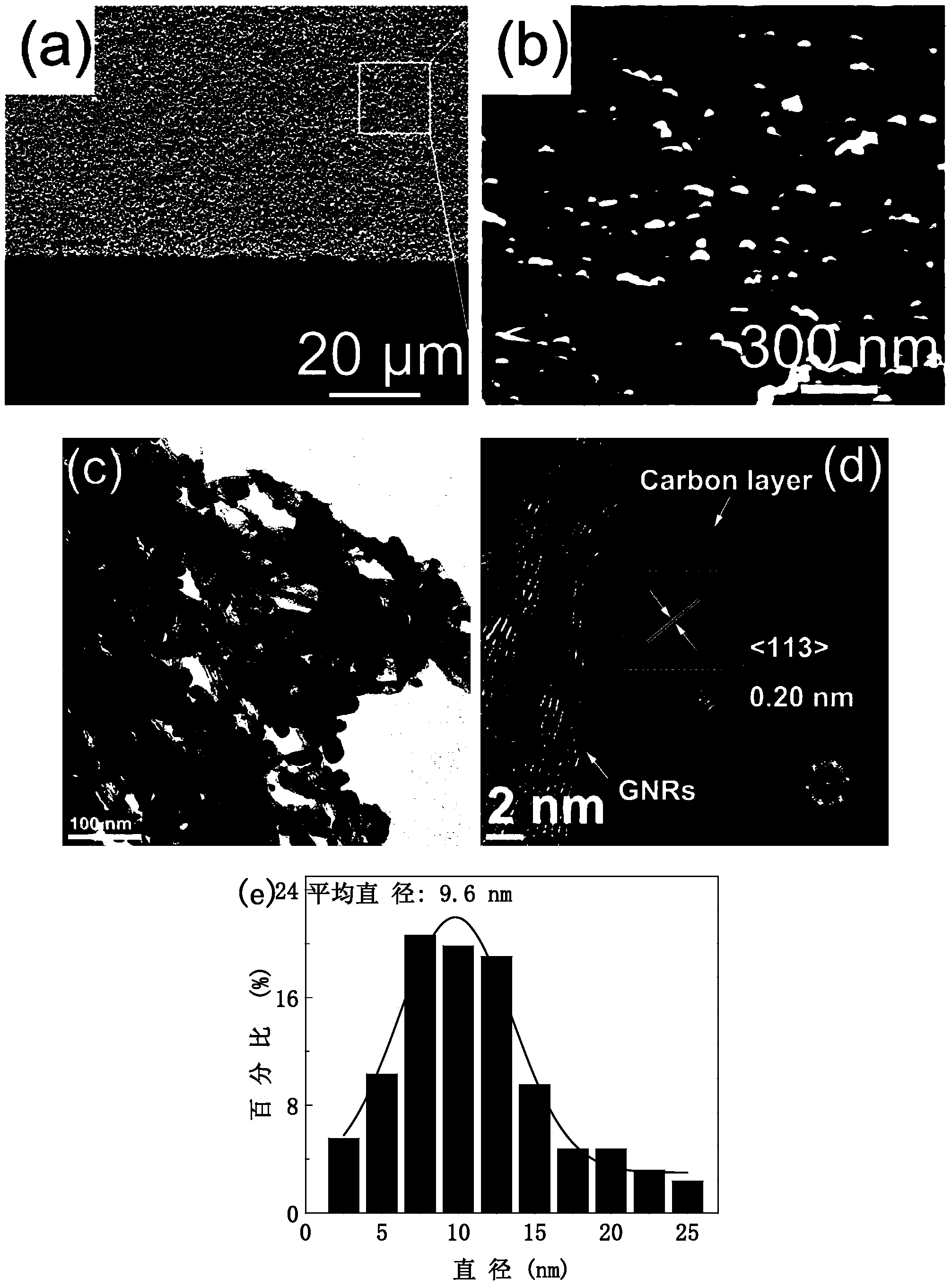

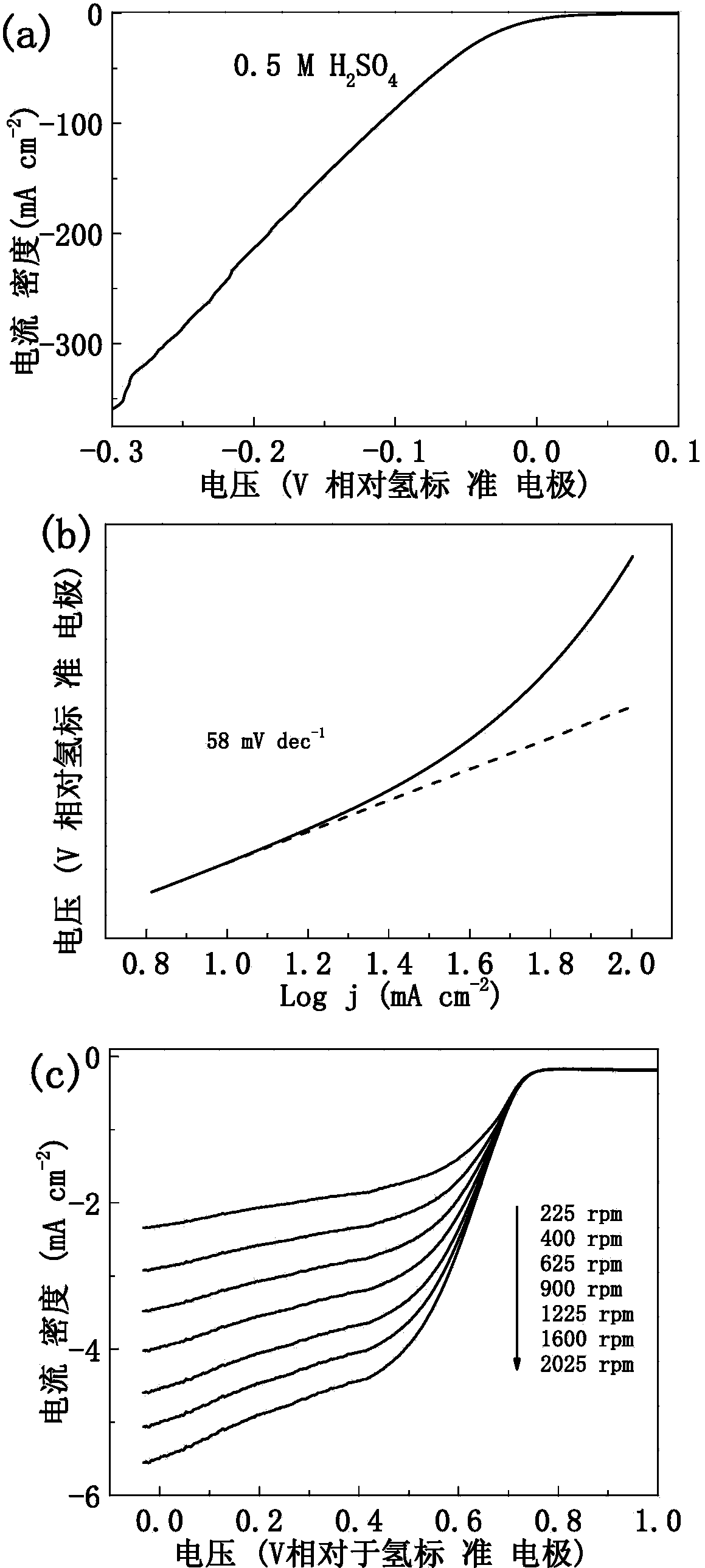

[0045] Embodiment 1: The CVD furnace used in the present invention is a hot wire-CVD furnace. The iron group element is Fe.

[0046] (1) Silicon wafers were ultrasonically cleaned with methanol, acetone and isopropanone for 15 minutes, N 2 blow dry. 9.5nm Al was sequentially evaporated by E-Beam Evaporation 2 o 3 , 1.2nm Fe.

[0047] (2) At a furnace temperature of 750°C, the gas flow rates are H 2 :200sccm, C 2 h 2 : 2 sccm, H through deionized water 2 Under the conditions of 200sccm, total air pressure of 25.5Torr, single tungsten wire, and 30W power, place the silicon wafer made in (1) 0.4cm in front of the tungsten wire, and set the total power of the tungsten wire to 0, the total air pressure was adjusted to 6.4 Torr, and the vertical array growth of single-walled carbon nanotubes was completed after 15 minutes of reaction.

[0048] (3) Replace a single tungsten wire with 4 tungsten wires, set the furnace temperature to 700°C, and the gas flow to H 2 :200sccm, C...

Embodiment 2

[0052] Embodiment 2: The CVD furnace used in the present invention is a hot wire-CVD furnace. The iron group element is Fe.

[0053] (1) Silicon wafers were ultrasonically cleaned with methanol, acetone and isopropanone for 15 minutes, N 2 blow dry. Evaporate 10nm Al sequentially by E-Beam Evaporation 2 o 3 , 1.0nm Fe.

[0054] (2) At a furnace temperature of 750°C, the gas flow rates are H 2 :190sccm, C 2 h 2 : 2.2 sccm, H through deionized water 2 The temperature is 210sccm, the total air pressure is 25Torr, the heating wire is a single tungsten wire, and the power is 32W. Place the silicon chip made in (1) 0.5cm in front of the tungsten wire, and set the power of the tungsten wire to 0 after 30s of reaction. The total air pressure was adjusted to 6.4 Torr, and the vertical array growth of single-walled carbon nanotubes was completed after 15 minutes of reaction.

[0055] (3) Replace a single tungsten wire with 4 tungsten wires, set the furnace temperature to 700°C,...

Embodiment 3

[0059] Embodiment 3: The CVD furnace used in the present invention is hot wire-CVD. The iron group element is Fe.

[0060] (1) Silicon wafers were ultrasonically cleaned with methanol, acetone and isopropanone for 15 minutes, N 2 blow dry. Evaporate 11nm Al sequentially by E-Beam Evaporation 2 o 3 , 1nm Fe.

[0061] (2) At a furnace temperature of 760°C, the gas flow rates are H 2 :190sccm, C 2 h 2: 1.8 sccm, H through deionized water 2 Under the conditions of 210sccm, total air pressure of 25.2Torr, single tungsten wire, and 35W power, place the silicon wafer made in (1) 0.5cm in front of the tungsten wire, and set the total power of the tungsten wire to 0, the total air pressure was adjusted to 6.4 Torr, and the vertical array growth of single-walled carbon nanotubes was completed after 15 minutes of reaction.

[0062] (3) Replace a single tungsten wire with 4 tungsten wires, set the furnace temperature to 700°C, and the gas flow to H 2 :200sccm, CH 4 : 0.5 sccm, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com