Carbon-sulfur combining sugar juice carbonation and clarifying method through CO2 generated from alcohol in production of sugar from sugarcane

A technology combining sugar and filling, applied in the production of sucrose, purification of sugar juice, purification by physical methods, etc., can solve problems such as air pollution, achieve strong adsorption capacity, eliminate energy waste and environmental pollution, and improve product quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

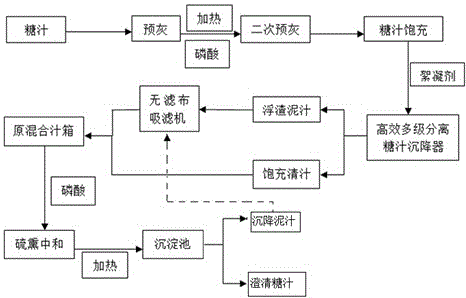

[0038] Such as figure 1 Shown, a kind of carbon-sulfur combined sugar juice is full and cleansing method, comprises the following steps:

[0039] Step (1), preash the sugar juice to pH 7.6, add phosphoric acid with a mass concentration of 30% to it, the amount of phosphoric acid added is 300ppm, and then heat to 65°C;

[0040] Step (2), add ash to the sugar juice heated in step (1) to a pH of 8.0, and then pass CO 2 Gas, for rapid filling, and the pH of the filling juice is controlled at 9.0; the CO 2 The gas is CO produced during alcohol production in sugar factories 2 Gas, the purity is above 99%;

[0041] Step (3), add flocculant to the sugar juice that has been rapidly filled in step (2), the amount of flocculant added is 3ppm, stir until the mixture is uniform, and then separate through the high-efficiency multi-stage separation sugar juice settler, separate Get scum and mud and clear juice;

[0042] In step (4), the scum and mud juice separated in step (3) are mixe...

Embodiment 2

[0045] Such as figure 1 Shown, a kind of carbon-sulfur combined sugar juice is full and cleansing method, comprises the following steps:

[0046]Step (1), preash the sugar juice to pH 7.6, add phosphoric acid with a mass concentration of 35% to it, the amount of phosphoric acid added is 280ppm, and then heat to 60°C;

[0047] Step (2), add ash to the sugar juice heated in step (1) to a pH of 8.3, and then pass CO 2 Gas, for fast filling, and the pH of the filling juice is controlled at 8.5; the CO 2 The gas is CO produced during alcohol production in sugar factories 2 Gas, the purity is above 99%;

[0048] Step (3), add polyacrylamide to the juice that has been quickly filled in step (2), the amount of polyacrylamide added is 5ppm, stir until the mixture is uniform, and then separate through the high-efficiency multi-stage separation sugar juice settler , separated to obtain scum and mud juice and full clear juice;

[0049] In step (4), mix the scum and mud juice separat...

Embodiment 3

[0052] Such as figure 1 Shown, a kind of carbon-sulfur combined sugar juice is full and cleansing method, comprises the following steps:

[0053] Step (1), preash the sugar juice to pH 7.6, add phosphoric acid with a mass concentration of 27% to it, the amount of phosphoric acid added is 270PPm, and then heat to 63°C;

[0054] Step (2), add ash to the sugar juice heated in step (1) to a pH of 8.5, and then pass CO 2 Gas, for rapid filling, and the pH of the filling juice is controlled at 9.6; the CO 2 The gas is CO produced during alcohol production in sugar factories 2 Gas, the purity is above 99%;

[0055] Step (3), add polyacrylamide to the juice that has been quickly filled in step (2), the amount of polyacrylamide added is 4ppm, stir until the mixture is uniform, and then separate through the high-efficiency multi-stage separation sugar juice settler , separated to obtain scum and mud juice and full clear juice;

[0056] In step (4), the scum and mud juice separated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com