A kind of slightly cross-linked thermoplastic elastomer and preparation method thereof

A thermoplastic elastomer and micro-crosslinking technology, applied in the field of polymer materials, can solve the problems of weak intermolecular force, poor mechanical strength, poor heat resistance of thermoplastic materials, etc., to enhance chemical force, reduce density, and reduce vulcanization The effect of temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

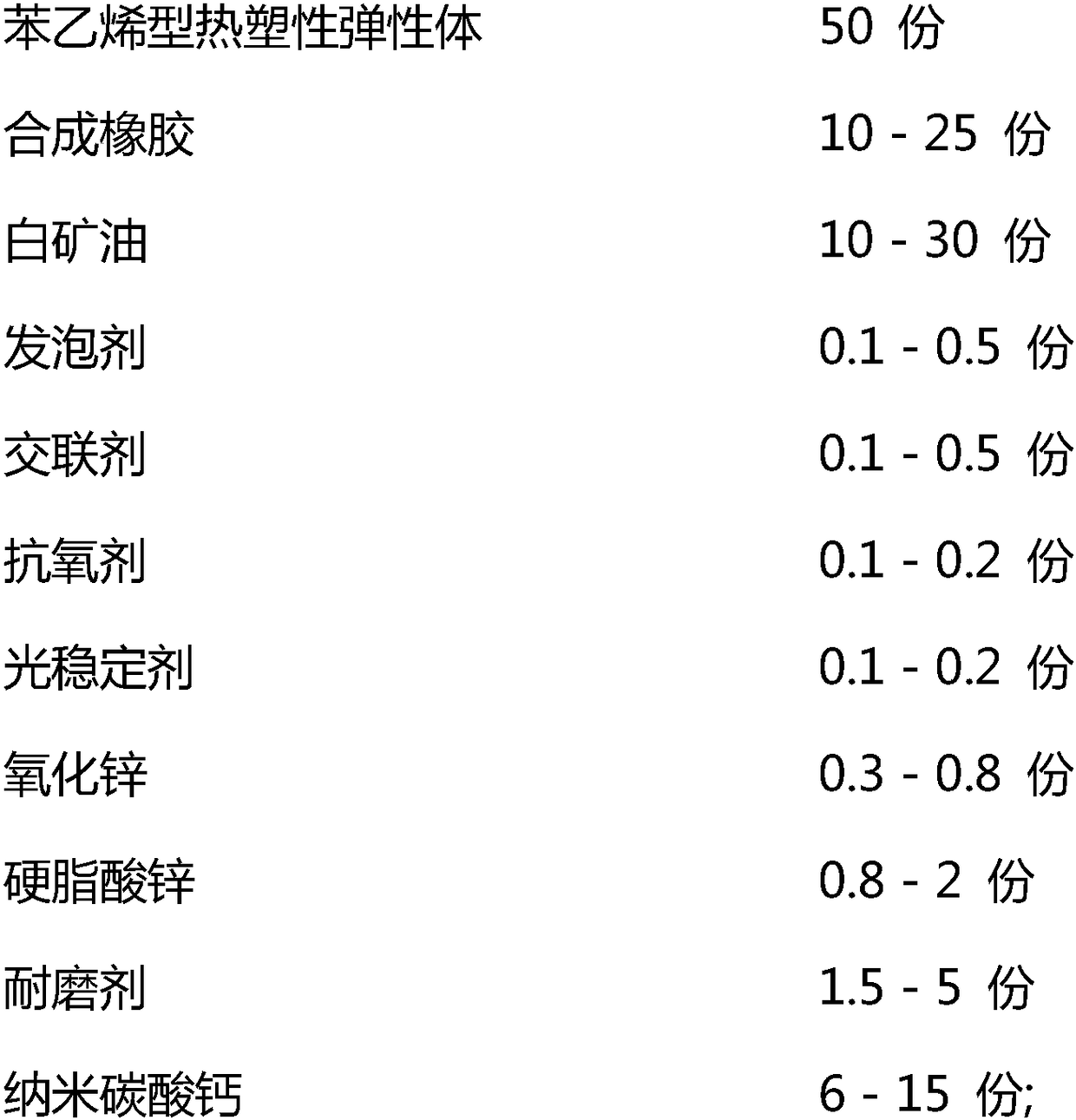

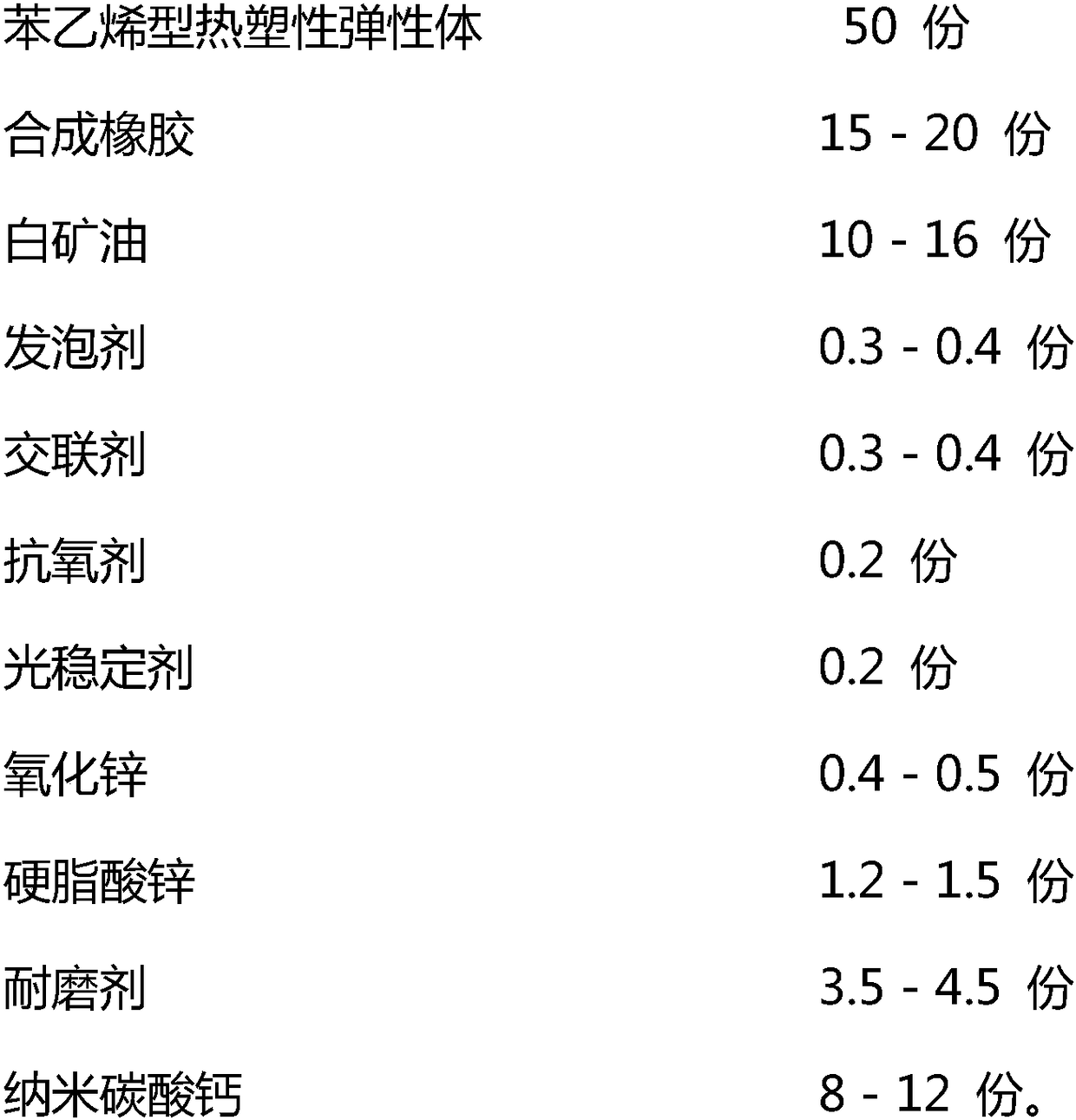

[0047] In this embodiment, a slightly crosslinked thermoplastic elastomer consists of the following components:

[0048] SBS YH-792 50 parts

[0049] Butadiene rubber BR 9000 15 parts

[0050] 16 parts white mineral oil

[0051] Foaming agent 0.3 parts

[0052] Cross-linking agent DCP 0.35 parts

[0053] Antioxidant 1076 0.2 parts

[0054] Light stabilizer UV-531 0.2 parts

[0056] Zinc stearate 1.3 parts

[0057] Anti-wear agent FY-500 4.0 parts

[0058] Nano calcium carbonate 10 parts.

[0059] Put the above component materials into the internal mixer for 12 minutes, control the discharge temperature to 131 degrees, and then press them into uniform sheets through the double-roller open mill, and finally cut the materials into specified sizes and put them into a large vulcanizing machine Taichung vulcanization molding, control vulcanization temperature 174 degrees, vulcanization time 240 seconds, to obtain micro-crosslinked thermoplastic...

Embodiment 2

[0062] In this example, the preparation method of a slightly cross-linked thermoplastic elastomer is basically the same as the preparation method in Example 1, the difference is:

[0063] 50 parts of SEBS YH-503, 12 parts of isoprene rubber, 23 parts of white mineral oil, 0.4 parts of foaming agent, 0.3 parts of crosslinking agent BIBP;

[0064] The vulcanization temperature is 172 degrees, and the vulcanization time is 280 seconds.

[0065] The micro-crosslinked thermoplastic elastomer prepared above has a density of 0.78 g / cm 3 , DIN wear-resistant 107 mm 3 , Shore hardness 51 degrees, dimensional shrinkage 0.41%, tear strength 24N / mm, tensile strength 4.6MPa, folding resistance 60,000 times without cracks, anti-slip coefficient smooth dry 0.98 wet 0.53.

Embodiment 3

[0067] In this example, the preparation method of a slightly cross-linked thermoplastic elastomer is basically the same as the preparation method in Example 1, the difference is:

[0068] 50 parts of SIS YH-1225, 18 parts of isoprene rubber, 30 parts of white mineral oil, 15 parts of nano calcium carbonate;

[0069] Banburying for 10 minutes, controlling the discharge temperature to 130 degrees, controlling the vulcanization temperature to 175 degrees, and the vulcanization time to 210 seconds.

[0070] The micro-crosslinked thermoplastic elastomer prepared above has a density of 0.83 g / cm 3 , DIN wear-resistant 99 mm 3, Shore hardness 53 degrees, dimensional shrinkage 0.30%, tear strength 31N / mm, tensile strength 4.5MPa, folding resistance 60,000 times without cracks, anti-slip coefficient smooth dry 0.87 wet 0.51.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com