Preparation method of liner rubber material for soft seal gate valve plates

A soft sealing and sizing technology, applied in the field of rubber-lined sizing, can solve the problems of short service life, high energy consumption and high cost, and achieve the effects of improving physical stability, low material cost and prolonging life.

Active Publication Date: 2015-02-18

铜陵天海流体控制股份有限公司

View PDF9 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

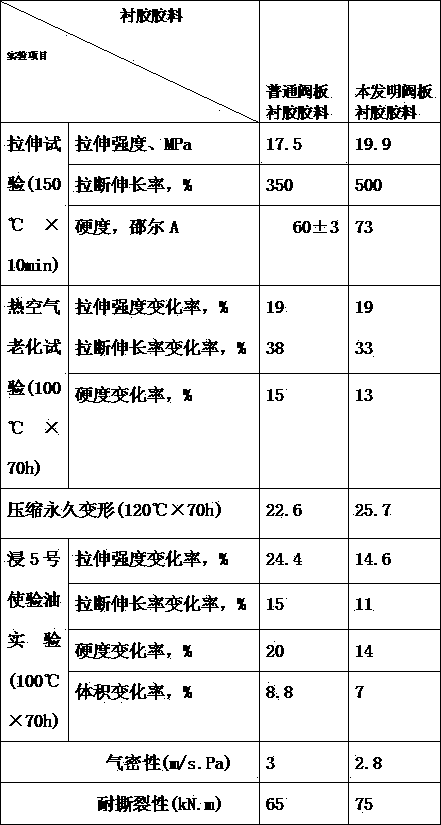

The technical problem to be solved by the present invention is that the rubber lining of the existing soft-sealed gate valve plate has unsatisfactory air tightness, poor heat resistance, poor memory and short service life, high cost, and high energy consumption in the manufacturing process. A rubber-lined rubber material for a soft-sealed gate valve plate and a preparation method thereof

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

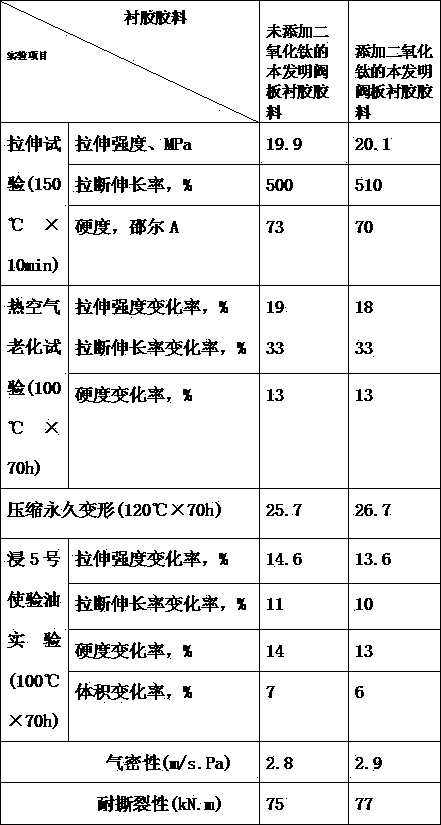

The invention discloses a preparation method of a liner rubber material for soft seal gate valve plates, which comprises the following steps: (1) preparation of rubber material A; (2) preparation of rubber material B; and (3) mixing of rubber material A and rubber material B: mixing the rubber material A and rubber material B in a weight ratio of (2-3):1, adding into an open mill, mixing and carrying out thin pass for 3-5 times. The rubber material can be prepared at lower temperature without plastification; the rubber material is vulcanized on the surface of the soft seal valve plate and the internal surface of the valve opening; the obtained liner rubber valve plate has the characteristics of favorable elasticity, favorable hardness, favorable air tightness, favorable heat resistance, favorable memory, low cost and the like; and the titanium dioxide added in the mixing process can enhance the physical stability of the rubber material and further prolong the service life.

Description

technical field The invention relates to a preparation method of a rubber-lined rubber material, in particular to a preparation method of a rubber-lined rubber material for a soft-sealed gate valve plate. Background technique Soft-sealed gate valve, industrial valve, the opening and closing part of the soft-sealed gate valve is a gate, the direction of movement of the gate is perpendicular to the direction of the fluid, the gate valve can only be fully opened and fully closed, and cannot be adjusted or throttled. The gate has two sealing surfaces, and the two sealing surfaces of the most commonly used mode gate form a wedge shape and a wedge angle. In terms of water quality: the soft-sealed gate valve avoids secondary pollution of water quality in the pipe network, reduces direct contact between water quality and metal, and prevents debris from blocking the valve. In terms of manufacturing: Soft-sealed gate valve has the advantages of light switch, reliable sealing, complet...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C08L27/12C08L51/04C08L23/16C08L93/04C08L83/04C08K13/04C08K7/10C08K3/36C08K3/08C08F253/00

CPCC08F253/00C08F255/06C08L51/04C08L2201/14C08L2201/08C08L2205/035C08L27/12C08L23/16C08L93/04C08L83/04C08K13/04C08K7/10C08K3/36C08K3/08C08K2003/2237C08F220/58C08F220/281C08F222/20

Inventor 王胜原

Owner 铜陵天海流体控制股份有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com