Efficient absorption method for 2-cyanopyridine

A technology of cyanopyridine and picoline ammonia, which is applied in the field of 2-cyanopyridine synthesis, can solve the problems of small contact area and insufficient contact of reaction gas, and achieve uniform spatial distribution, small particle diameter and dense spatial distribution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

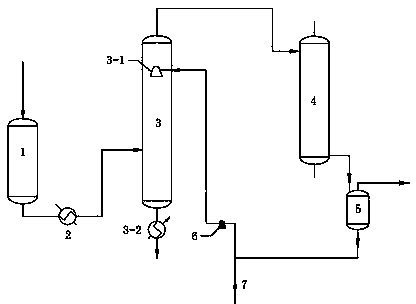

[0023] like figure 1 As shown, the reaction mixture gas produced by the ammonia oxidation in the ammonia oxidation reactor 1 is initially cooled to 200-230 °C by the heat exchanger 2, and then enters the absorption tower 3, and is sprayed with the high-pressure fine water mist nozzle 3-1. The high-pressure fine water mist out is subjected to heat exchange and material exchange, and the condensed product sinks into the bottom of the absorption tower 3, is sent to the follow-up 2-cyanopyridine separation and purification system after being cooled by the cooler 3-2; The condensed gas enters the tubular cooler 4 from the top of the absorption tower 3 for cooling, and the cooled liquid phase enters the storage tank 5, and after being merged with the water inlet pipeline 7, it is pressurized by the high-pressure water mist pump 6 and sent to the high-pressure fine mist pump. Water mist nozzle 3-1; non-condensable gas is discharged from the top of the storage tank 5 and enters the t...

Embodiment 2

[0027] A 2-cyanopyridine high-efficiency absorption method: in the process of preparing 2-cyanopyridine by ammoxidation of 2-picoline, high-pressure fine water mist is used as an absorbent, and the temperature obtained after the ammoxidation reaction and preliminary cooling is The mixed gas at 205-210°C is cooled and absorbed; the particle size of the high-pressure fine water mist is less than 50 μm. The high-pressure fine water mist is sprayed from the high-pressure fine water mist nozzle located at the top of the absorption tower, and the 2-cyanopyridine aqueous solution obtained at the bottom of the tower stays in the absorption tower for no more than 0.5 h. Then, it is pumped to Subsequent separation and purification are carried out in the rectification tower. The water used in the high-pressure water mist is pure water, which is used once and does not circulate directly. details as follows:

[0028] The preheated 2-picoline (flow rate 10.0 kg / h), ammonia, air and other ...

Embodiment 3

[0030] A 2-cyanopyridine high-efficiency absorption method: in the process of preparing 2-cyanopyridine by ammoxidation of 2-picoline, high-pressure fine water mist is used as an absorbent, and the temperature obtained after the ammoxidation reaction and preliminary cooling is The mixed gas at 218-225°C is cooled and absorbed; the particle size of the high-pressure fine water mist is less than 50 μm. The high-pressure fine water mist is sprayed from the high-pressure fine water mist nozzle located at the top of the absorption tower, and the 2-cyanopyridine aqueous solution obtained at the bottom of the tower stays in the absorption tower for no more than 0.5 h. Then, it is pumped to Subsequent separation and purification are carried out in the rectification tower. The water used in the high-pressure water mist is pure water, which is used once and does not circulate directly. details as follows:

[0031] The preheated 2-picoline (flow rate: 9.5 kg / h) and air mixed gas enters...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com