Synthetic method of 5-nonyl salicylaldoxime

A nonylsalicylaldoxime and synthetic method technology, applied in oxime preparation, organic chemistry, etc., can solve the problems of high reaction temperature, high equipment requirements, and many side reactions, and achieve mild reaction conditions, low equipment requirements, safety and convenience The effect of the operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

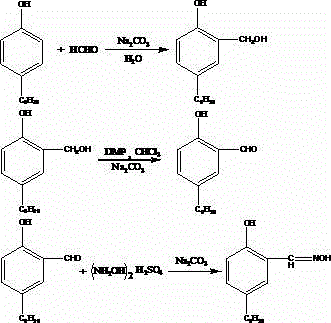

Image

Examples

Embodiment 1

[0023] Put 220g of 4-nonylphenol and 200g of formaldehyde solution with a mass concentration of 30% into a 1L four-neck flask, add 18g of sodium carbonate, stir and heat up to 70°C, keep the temperature for 2 hours, and then stand for stratification; discard the water layer, and the organic Transfer the layer into a 1L four-neck flask and add 200ml of chloroform, then add 178g of Dess-Martin reagent (produced by Weifang Weimeng Chemical Co., Ltd.) and react at 25°C for 2h. After washing with sodium thiosulfate aqueous solution and 200g deionized water, let it stand for stratification, discard the water layer, transfer the organic layer into a 1L four-necked flask, add 300g of 25% mass concentration of sodium carbonate aqueous solution, and drop in 30% The mass concentration of hydroxylamine sulfate aqueous solution is 328g. After the dropwise addition, keep it warm at 60°C for 3 hours, add 60g of 20% mass concentration of sulfuric acid aqueous solution to neutralize (pH is 6...

Embodiment 2

[0026] Put 220g of 4-nonylphenol and 150g of 30% mass concentration formaldehyde solution into a 1L four-necked flask, add 10g of sodium hydroxide, stir and raise the temperature to 50°C, keep the temperature for 2 hours and then let it stand for stratification, discard the water layer, and put Transfer the organic layer into a 1L four-neck flask and add 200ml of chloroform, add 170g of Dess-Martin reagent (produced by Weifang Weimeng Chemical Co., Ltd.) and react at 30°C for 2h. After washing with sodium thiosulfate aqueous solution and 200g deionized water, let it stand for stratification, discard the water layer, transfer the organic layer to a 1L four-necked flask, add 175g of 25% mass concentration of sodium hydroxide aqueous solution, and drop in 30% The mass concentration of hydroxylamine sulfate aqueous solution is 300g, after the dropwise addition is completed, it is incubated at 50°C for 3 hours, and 10g of 20% mass concentration of sulfuric acid aqueous solution i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com